A Fatigue Crack Growth Rate Prediction Method Based on Artificial Neural Network

A technology of fatigue crack propagation and neuron network, which is applied in the application field of artificial neuron network, can solve problems such as not being completely linear, and achieve the effect of comprehensive methods, strong scalability and strong expansibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

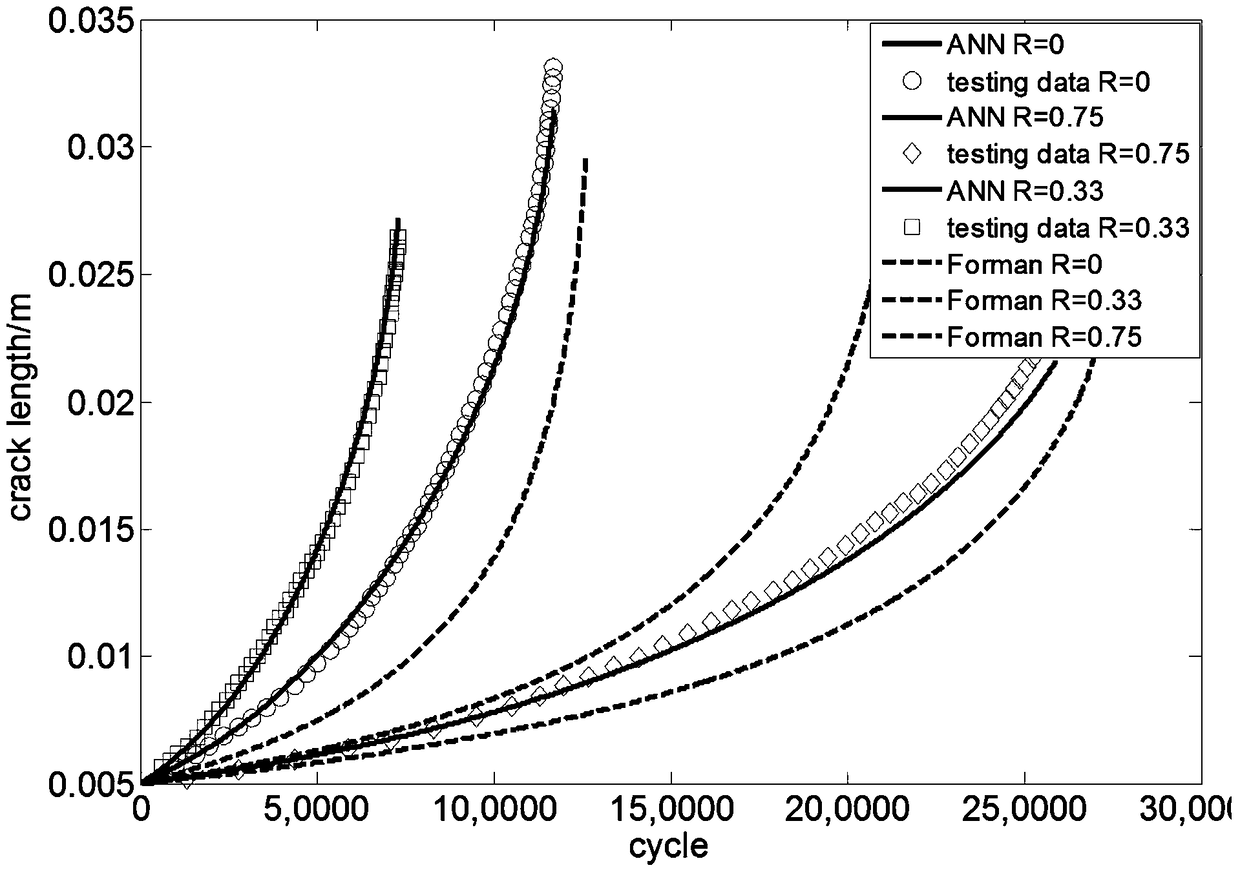

[0056] The present invention uses experimental data to train the artificial neuron network as the following steps:

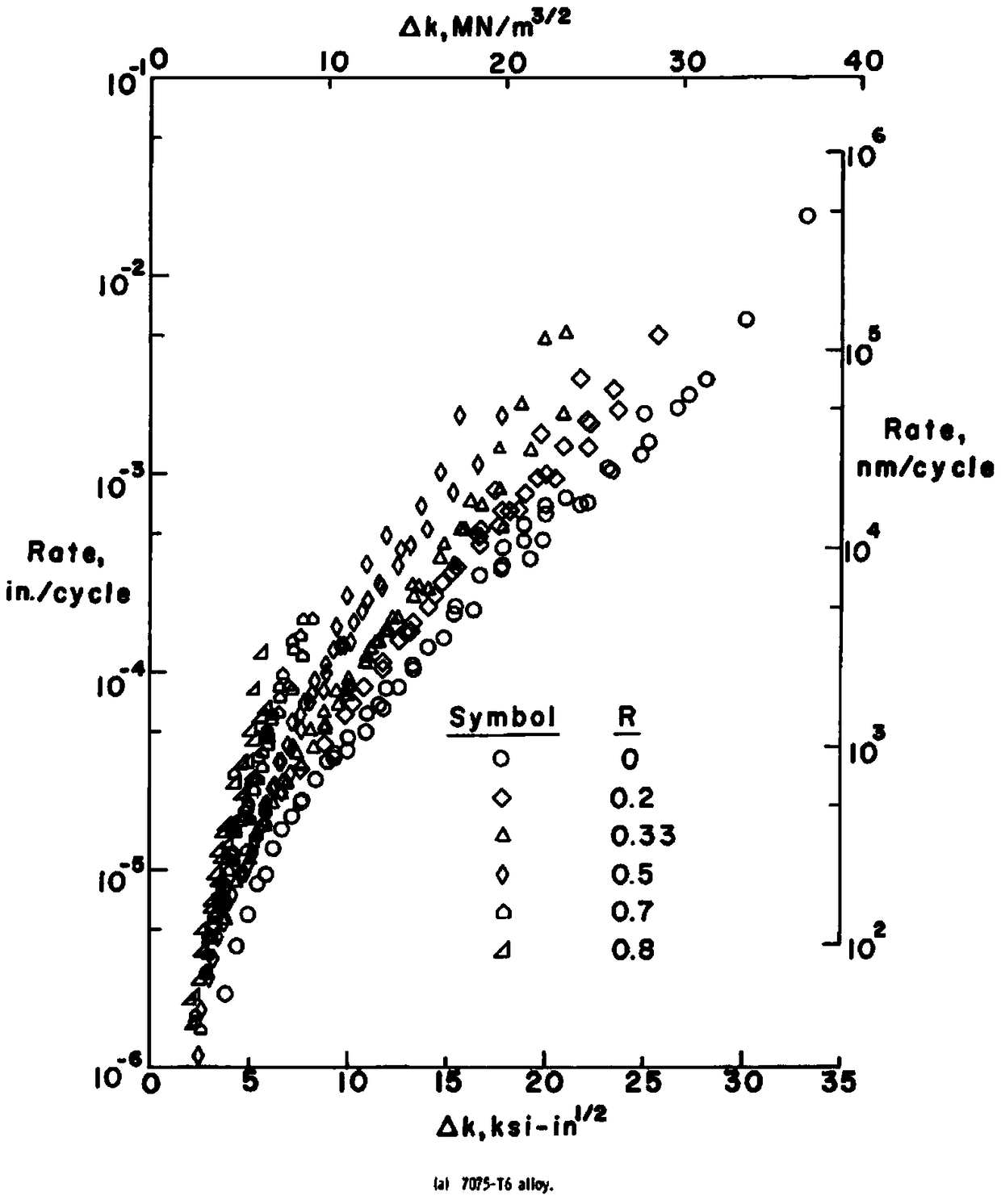

[0057] Step 1: Obtain the load Kmax, stress ratio R, and fatigue crack growth rate da under the corresponding load; import the experimental data, and refer to the specific data figure 1 : Including stress intensity factor series Kmax, stress ratio series R, single crack growth length series da;

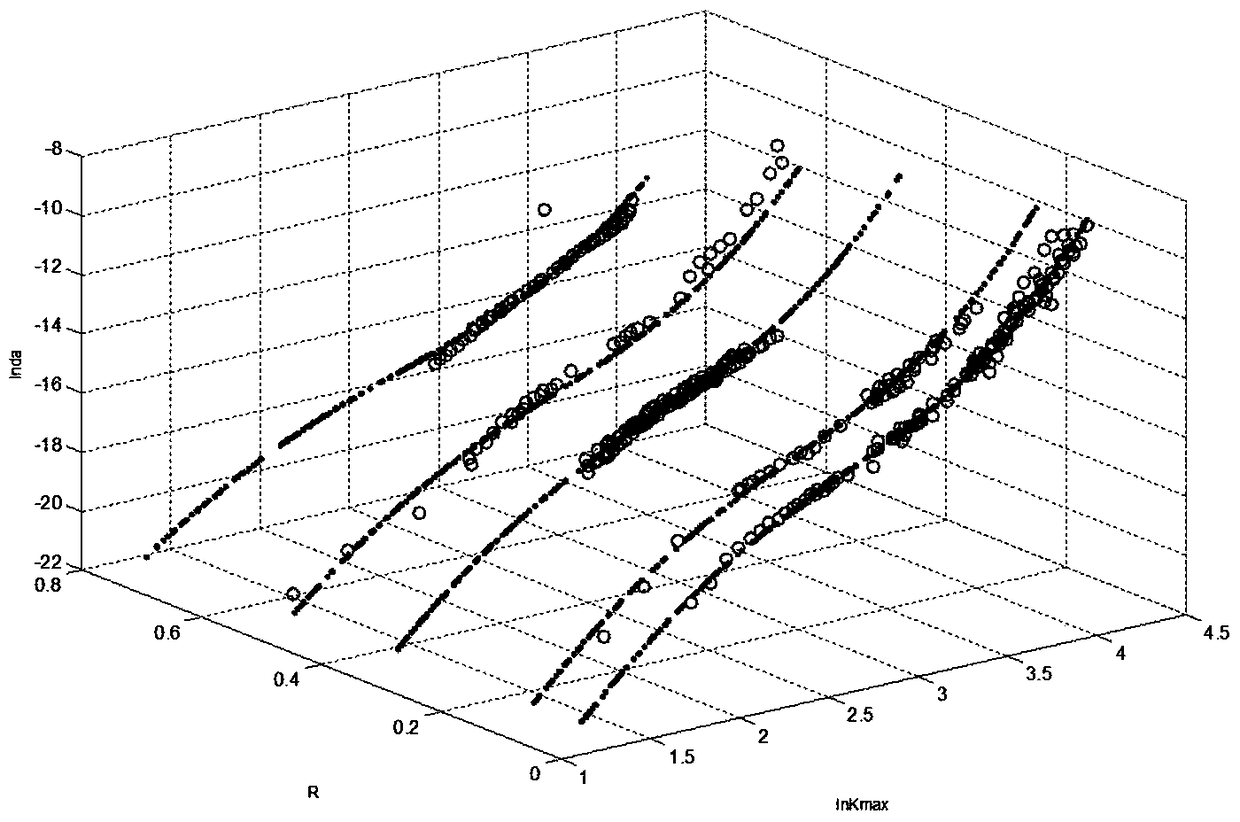

[0058] Step 2: Preprocess the experimental data: first logarithmize the experimental data Kmax, da, and then normalize the experimental data, and obtain the relevant normalization parameters ps1, ps2 at the same time;

[0059] Step 3: Adjust the mean square error target of the artificial neuron network, the expansion speed of the radial basis function, the maximum number of neurons, and use the normalized data to train the artificial neuron network;

[0060] Step 4: Create arrays tx1, tx2, ty, assign 1000 numbers uniformly distributed between 0 and 1 to tx1, assign 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com