Independently-driven untwisting mechanism for cabling machine

A technology of independent driving and back-twisting mechanism, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of difficult processing and assembly, easy damage, complex structure, etc., to achieve simple operation, reasonable structure, and simplified structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

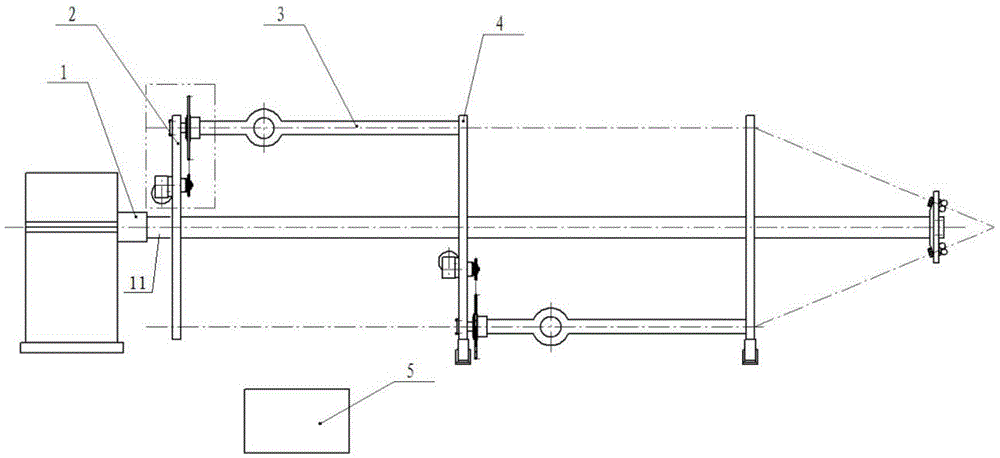

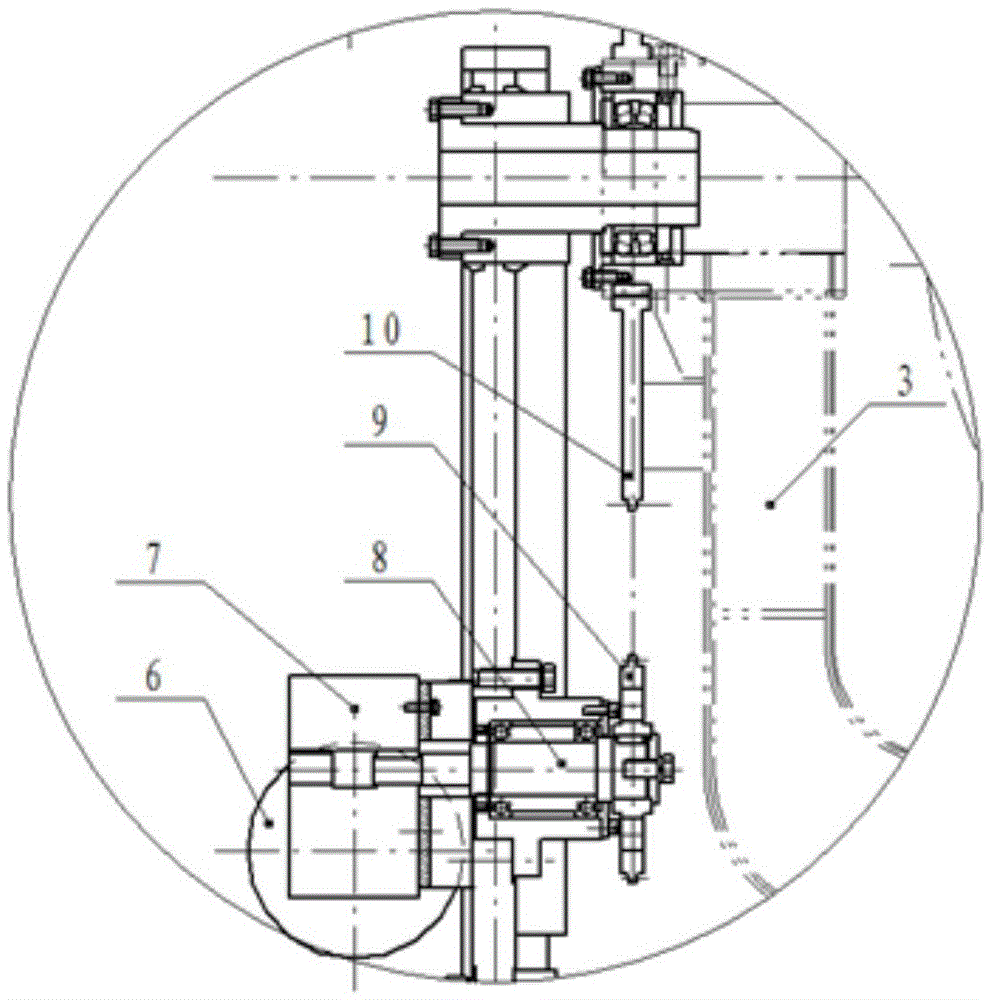

[0012] see figure 1 , 2 , an independently driven twist-back mechanism used on a cable forming machine, including a brush ring 1, an electric control system 5, front and rear capstans 2, 4 and a wire reel rotatably installed between the front and rear capstans 2, 4 The frame 3, the brush ring 1 includes slip rings and electric brushes, the outer side of the front winch 2 is equipped with a twist-back motor 6, and the inner side of the front winch 2 is rotated with a transmission shaft 8, and the twist-back motor 6 is connected to the transmission shaft 8. Drive shaft 8 is equipped with driving wheel 9, and one end of wire reel frame 3 is equipped with driven wheel 10, and driving wheel 9 is connected with driven wheel 10 transmission; And be electrically connected with electric control system 5, and electric brush is installed on the front capstan 2, and is electrically connected with back twisting motor 6.

[0013] In the present invention, the untwisting motor 6 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com