Power battery module

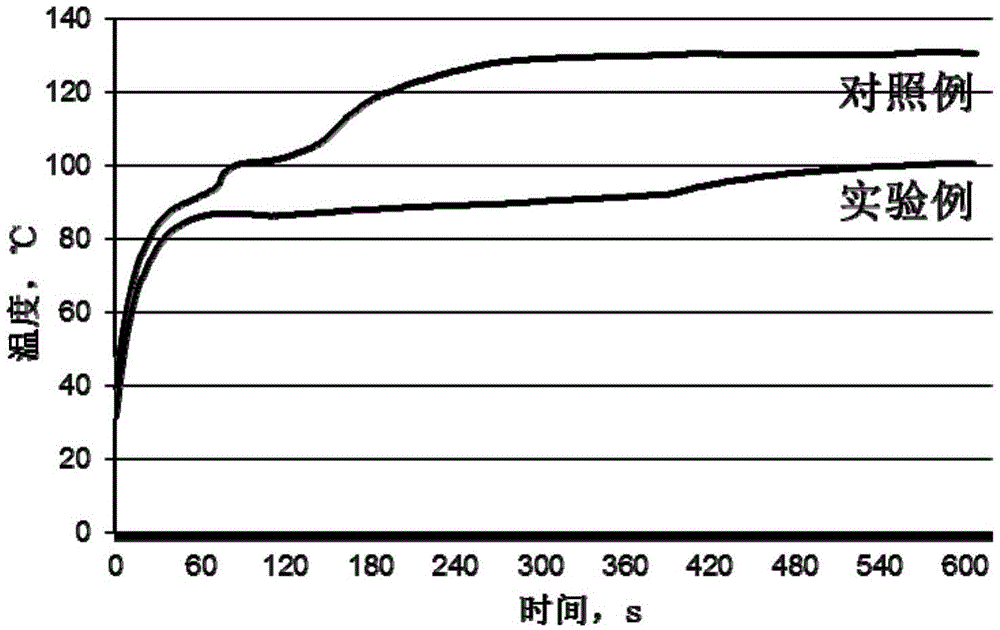

A power battery and module technology, applied in the field of energy storage devices, can solve the problems of thermal runaway of cells, thermal runaway of adjacent cells, failure of battery modules and battery packs, etc., to prevent accumulation and reduce the potential risk of thermal runaway Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

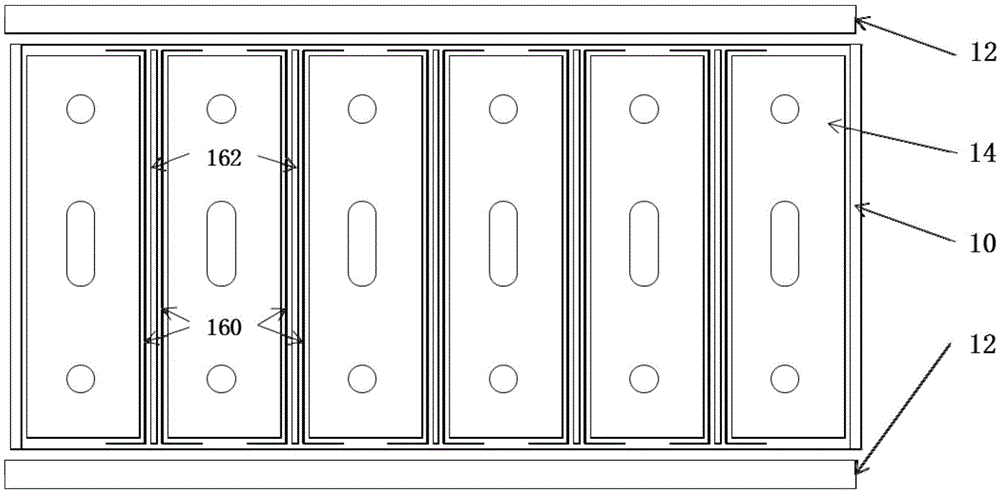

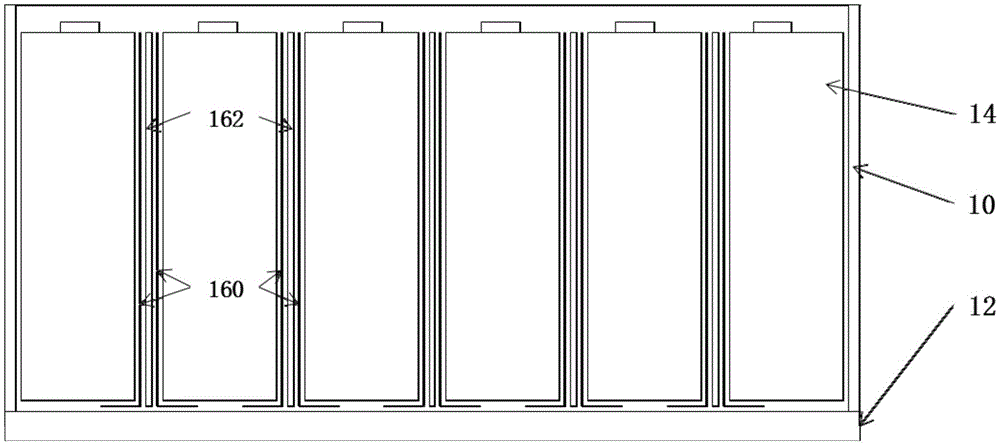

[0045] The present application will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings. "Front", "rear", "left", "right", "upper" and "lower" mentioned in the text are all based on the placement state of the power battery module in the drawings.

[0046] like Figures 1 to 3 As shown, the embodiment of the present application provides a power battery module, including a module case 10 , a heat dissipation system 12 , a battery cell 14 and a thermal runaway prevention structure 16 . Among them, several battery cells 14 are regularly arranged side by side in the module casing 10, serving as the power supply core of the battery module. The heat dissipation system 12 is arranged on the module casing 10, and generally absorbs heat inside the module casing 10 through a thermally conductive film layer with high thermal conductivity, and transfers the absorbed heat to the outside of the module casing 10 for dissipation....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com