Servo motor with inertia disc and its installation method

A technology of servo motors and inertia discs, applied in the field of servo motors, can solve the problems of time-consuming and labor-intensive, cost-increasing, inflexible and inconvenient inertia adjustment, etc., and achieve the effects of cost reduction, convenient installation, and flexible and convenient inertia adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

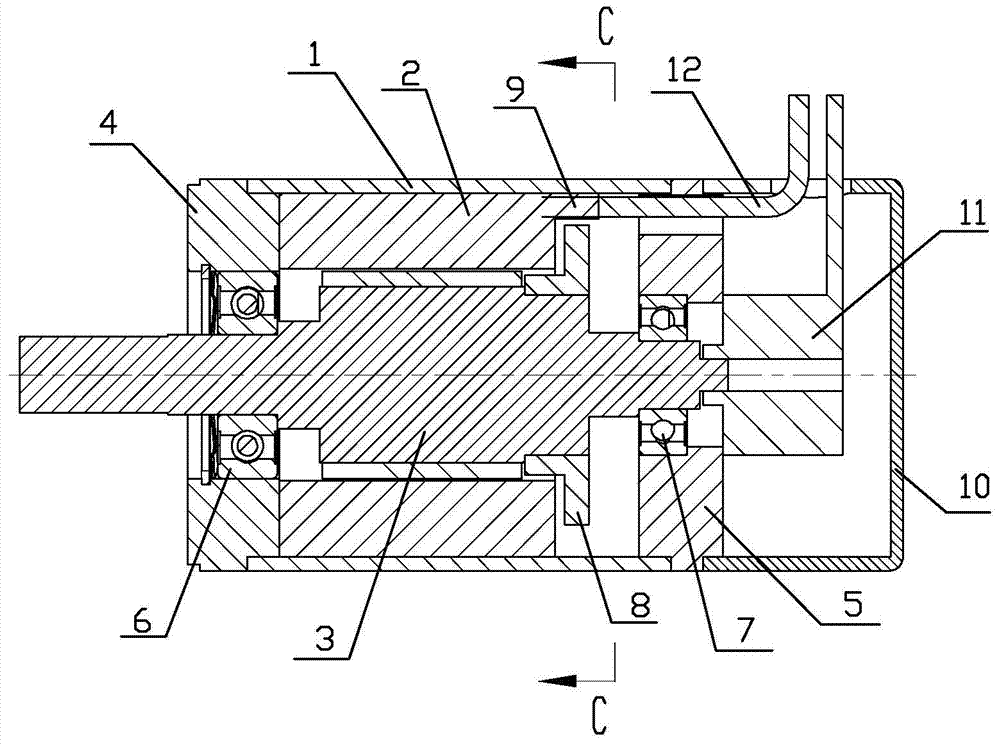

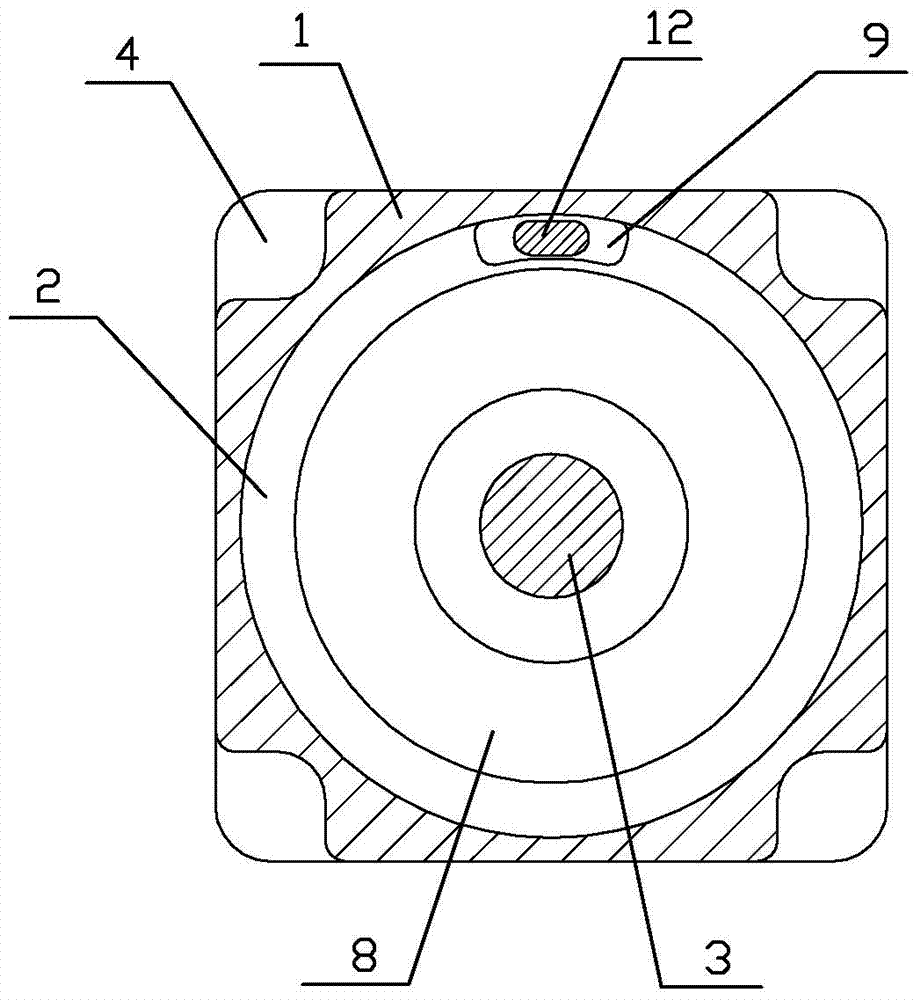

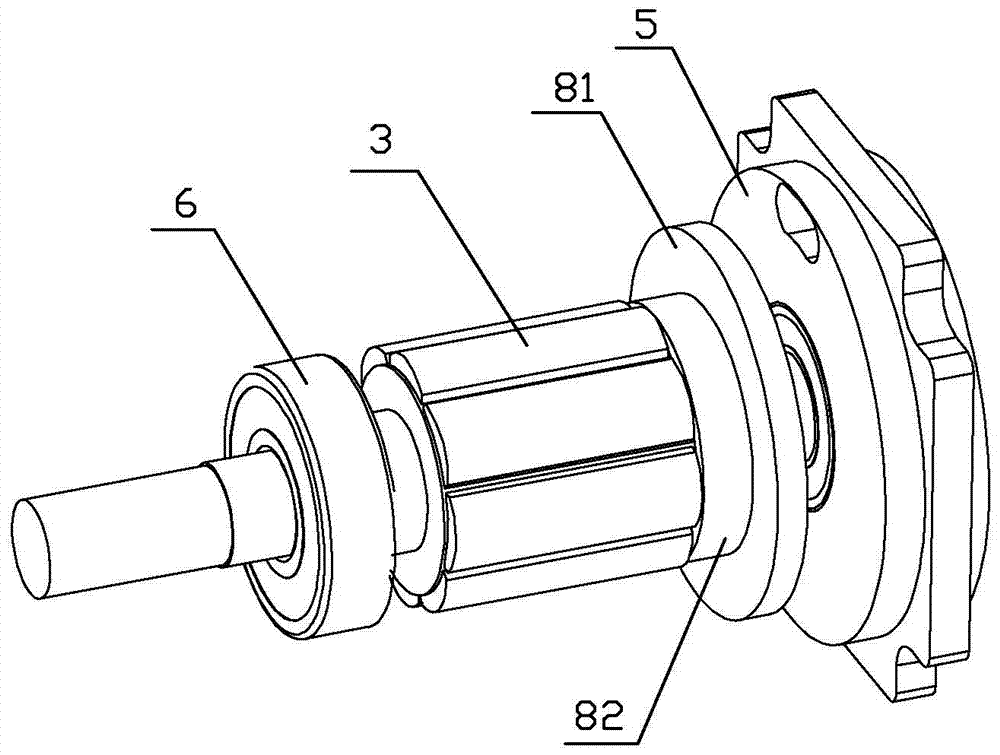

[0026] Embodiment: the servomotor of the band inertia disc of the present embodiment, as figure 1 , figure 2 , Figure 4 As shown, it includes a housing 1 and a stator 2 and a rotor 3 installed in the housing 1. The front end of the housing 1 is connected with a front end cover 4, and the rear end of the housing 1 is connected with a rear end cover 5. The front end cover 4 and the rotor A front bearing 6 is installed between the front ends of the rotor 3, a rear bearing 7 is installed between the rear end cover 5 and the rear end of the rotor 3, the stator 2 is filled with potting glue, and the potting glue surrounds the stator 2 to become a potting stator. There is a wire fixing body formed by filling glue protruding from the rear end surface of the glue stator. The wire 12 is embedded in the strip-shaped protrusion 9 and passes through the strip-shaped protrusion 9 and passes through the rear end cover 5 to lead out of the end cover. An inertia disk 8 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com