Variable-frequency motor and fan for refrigerator

A frequency conversion motor and freezer technology, which is used in machines/engines, synchronous motors with static armatures and rotating magnets, and electromechanical devices, etc., can solve problems such as poor heat dissipation, small rotational inertia, and low efficiency, and achieve smooth rotation Large rotor inertia and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Embodiments of the present invention will be described in detail below.

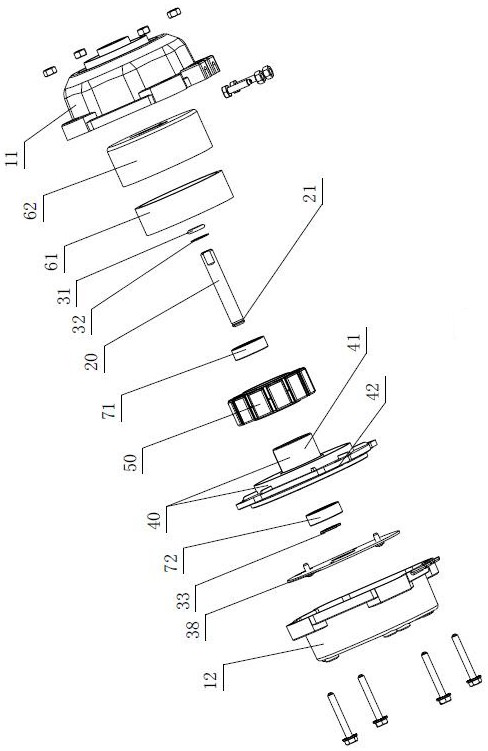

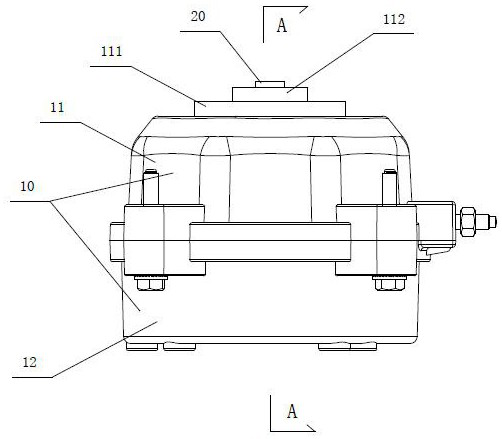

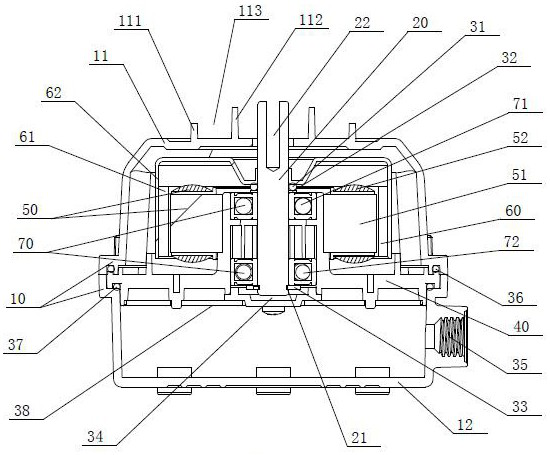

[0054] see Figure 1 to Figure 6 As shown, a frequency conversion motor for a refrigerator provided by the present invention includes a housing 10, a main shaft 20, a circuit board 38 installed in the housing 10, a stator seat 40, a stator 50, a magnetic ring 61, a rotor housing 62, and an elastic washer 31. Bakelite gasket 32, bearing seat 70, stator seat 40 includes cylinder 41, base plate seat 42, the rear end of cylinder body 41 is connected to the front side of base plate seat 42, stator base 40 is fixed to housing 10 through base plate seat 42 connection, the bearing seat 70 is installed in the cylinder 41, the stator 50 includes an iron core 51 and a three-phase winding coil 52, the iron core 51 of the stator 50 adopts a twelve-slot structure, and the three-phase winding coil 52 is installed in the cylinder through the iron core 51 41, the magnetic ring 61 is installed in the rotor shell 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com