Novel turbine acting device

A technology of power and turbine, applied in the direction of blade support components, stators, engine components, etc., can solve the problems of high manufacturing cost, reduced rigidity of wheel axle, high fuel consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The new turbine work device can be applied to work of various high-energy gases, such as high-pressure steam, high-temperature and high-pressure gas, high-energy compressed air, etc. In order to save space, only high-temperature and high-pressure gas is used as the working medium below, and the following seven examples are passed. And in conjunction with its accompanying drawing, the novel turbine power device is further elaborated.

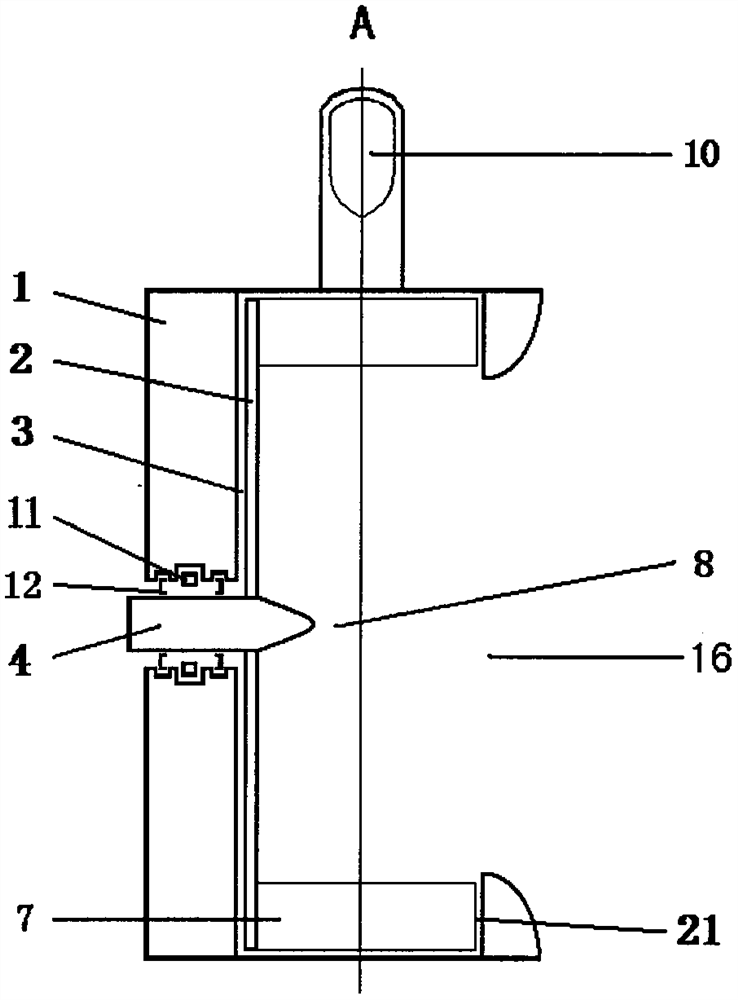

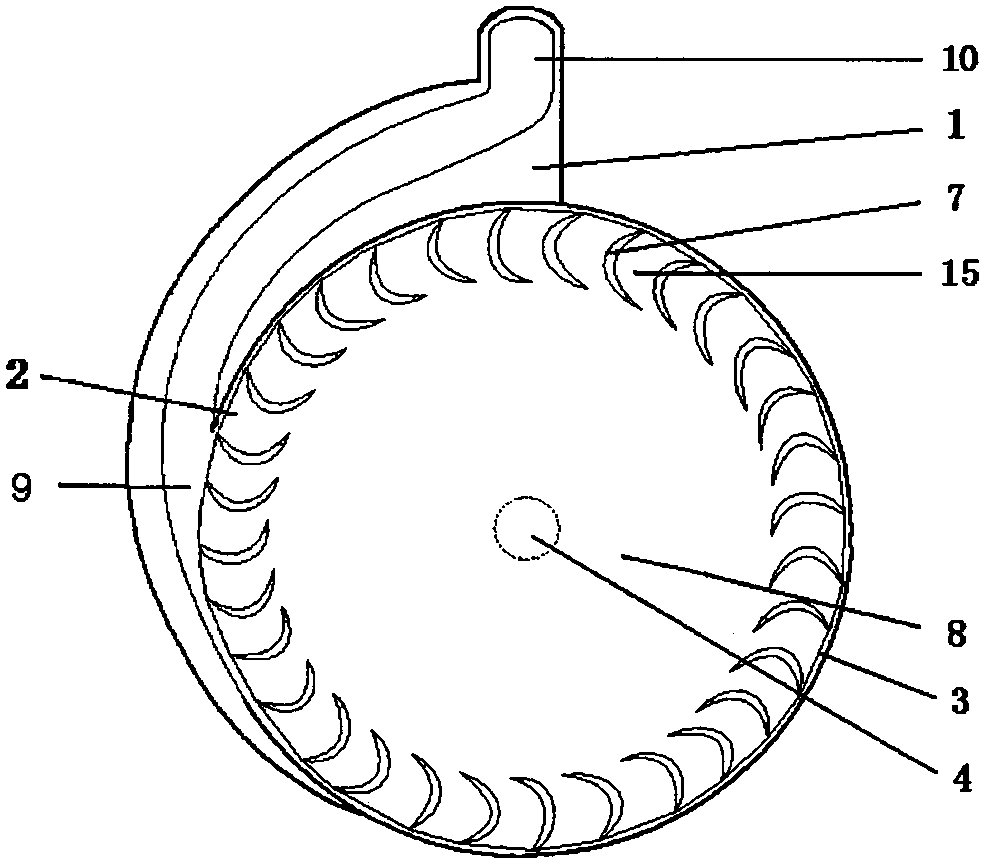

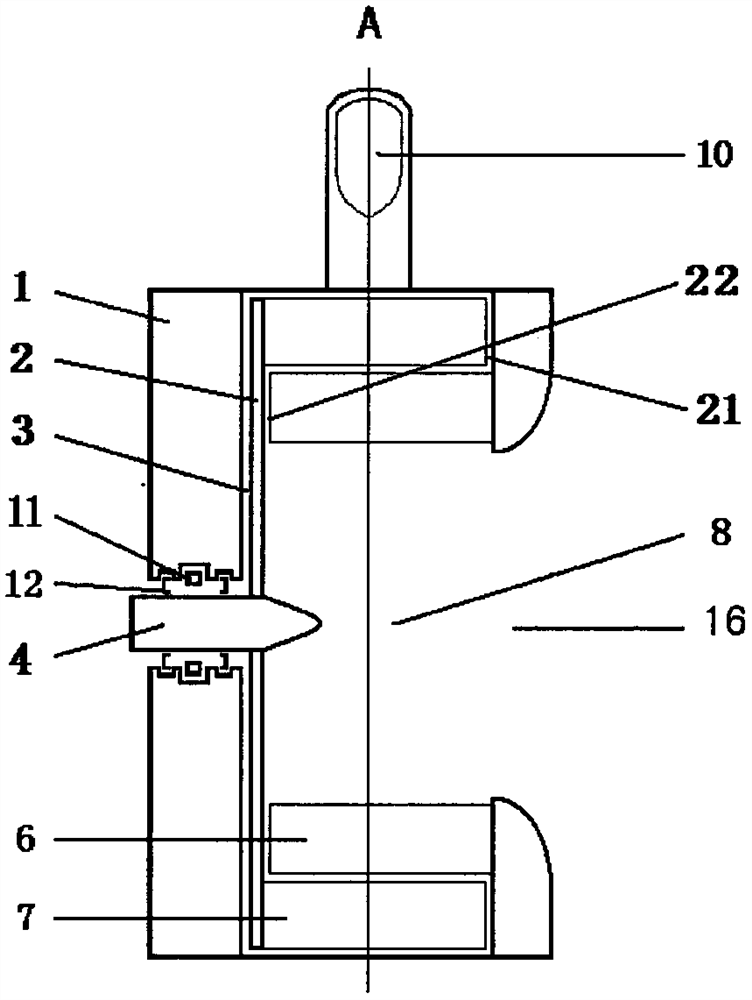

[0031] figure 1 , figure 2 The first embodiment of the novel turbine power device is shown together. As can be seen from the accompanying drawings, the new turbine power device shown in this embodiment is mainly composed of a housing 1, a wheel body 2, a wheel shaft 4, and a basic rotor. , there is a wheel cavity 3 in the housing 1, the wheel body 2 is installed in the wheel cavity 3, the basic rotor is installed on the side of the wheel body 2, the wheel shaft 4 is installed on the center of the wheel body 2, and the wheel shaft 4 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com