A device, method and system for monitoring a network of fluid-carrying conduits

A technology for monitoring equipment and equipment, which can be used in pipeline systems, water supply pipeline systems, general control systems, etc., and can solve problems such as discoloration, biofilm erosion, and impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

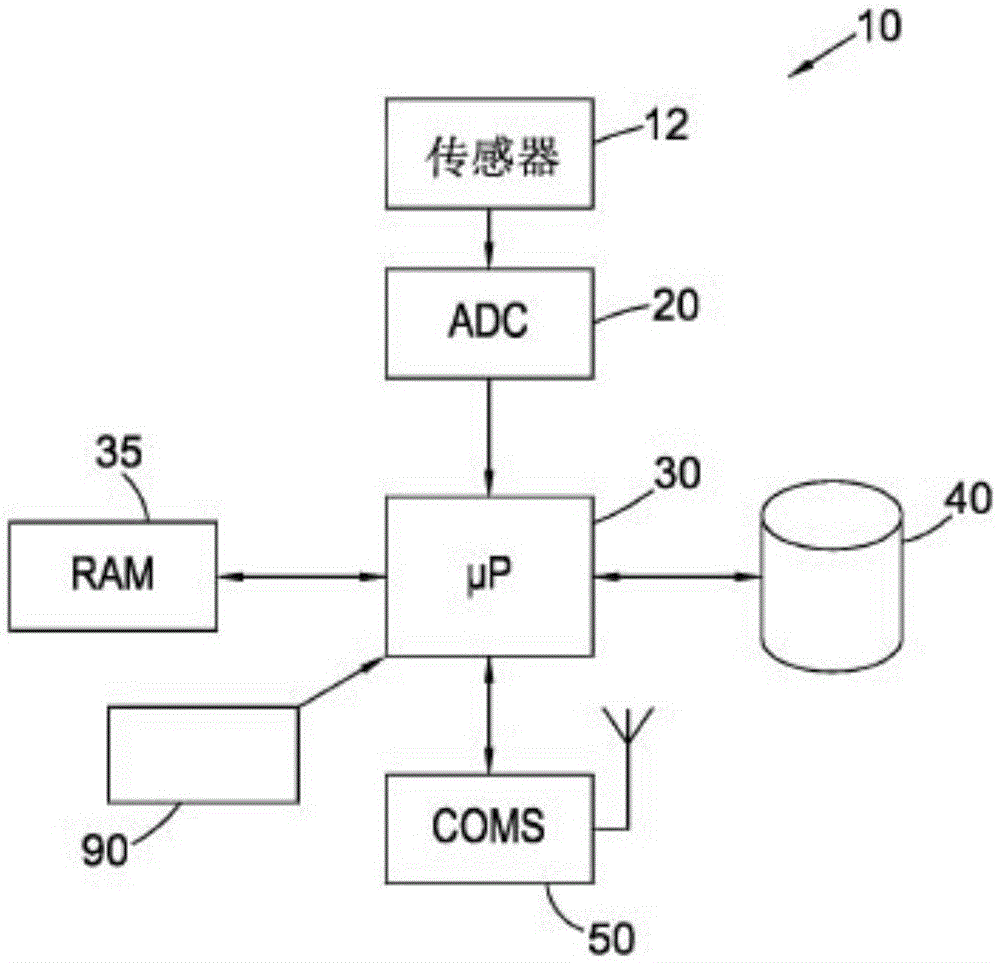

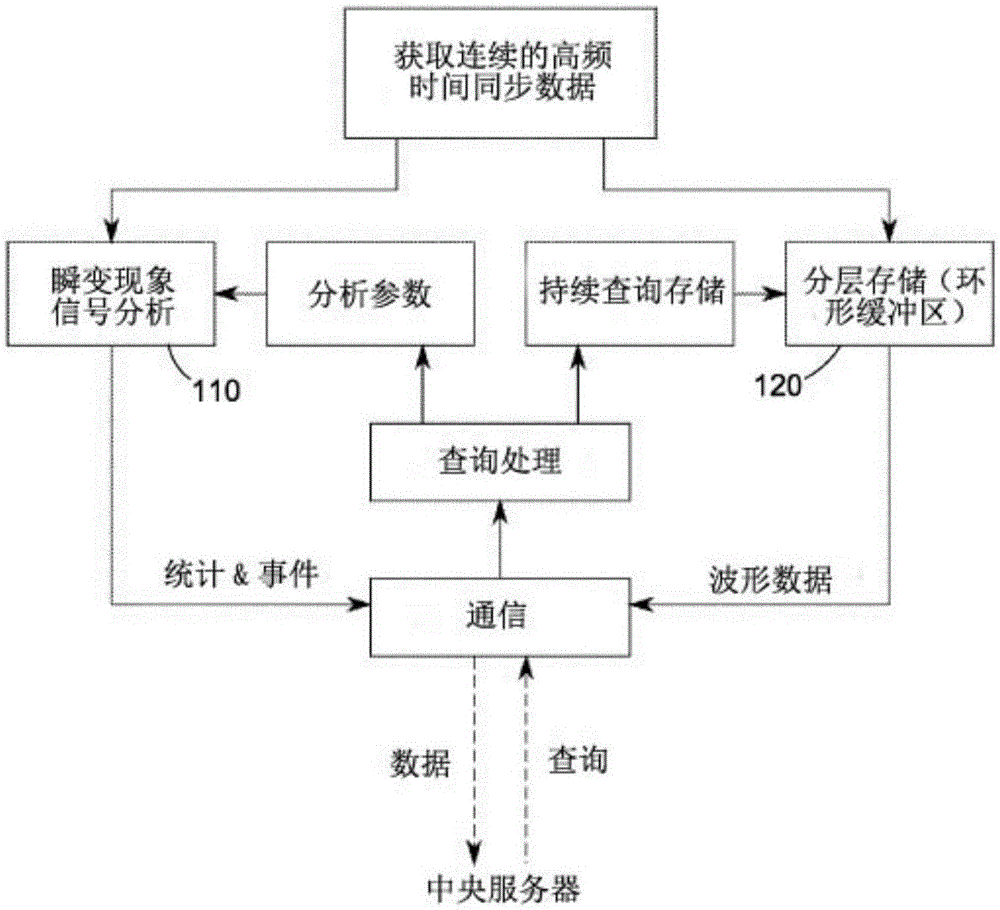

[0098] Water transmission and distribution systems are critical infrastructure with a high level of control and severe consequences of failure. Continuous monitoring of loading conditions due to dynamic hydraulic behavior helps maintain the structural strength of infrastructure for aging pipelines and protects water quality. Monitoring and controlling dynamic hydraulic conditions requires new methods and instrumentation for collecting continuous high-frequency time-synchronized data and managing large volumes of data under severe electrical constraints. The monitoring system should also be able to query in near real time and retroactively query the extracted, high-frequency, time-synchronized hydraulic data for any time period. This is particularly useful when blowouts or other failures occur and causal analysis is required to identify failure mechanisms by extracting high-frequency, time-synchronized data before and at the time of system failure.

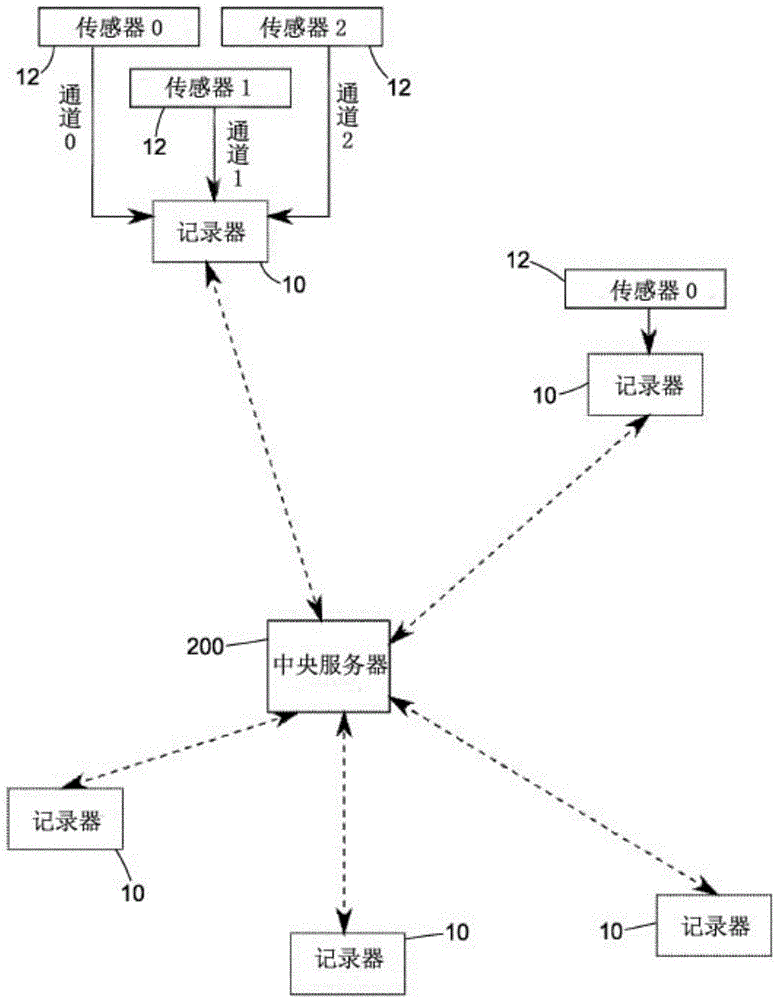

[0099] figure 1 An overvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com