Filter

A filter and filter cartridge technology, which is used in filtration and separation, mobile filter element filters, chemical instruments and methods, etc., can solve the problems of poor water quality, difficult removal of impurities, and low water treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

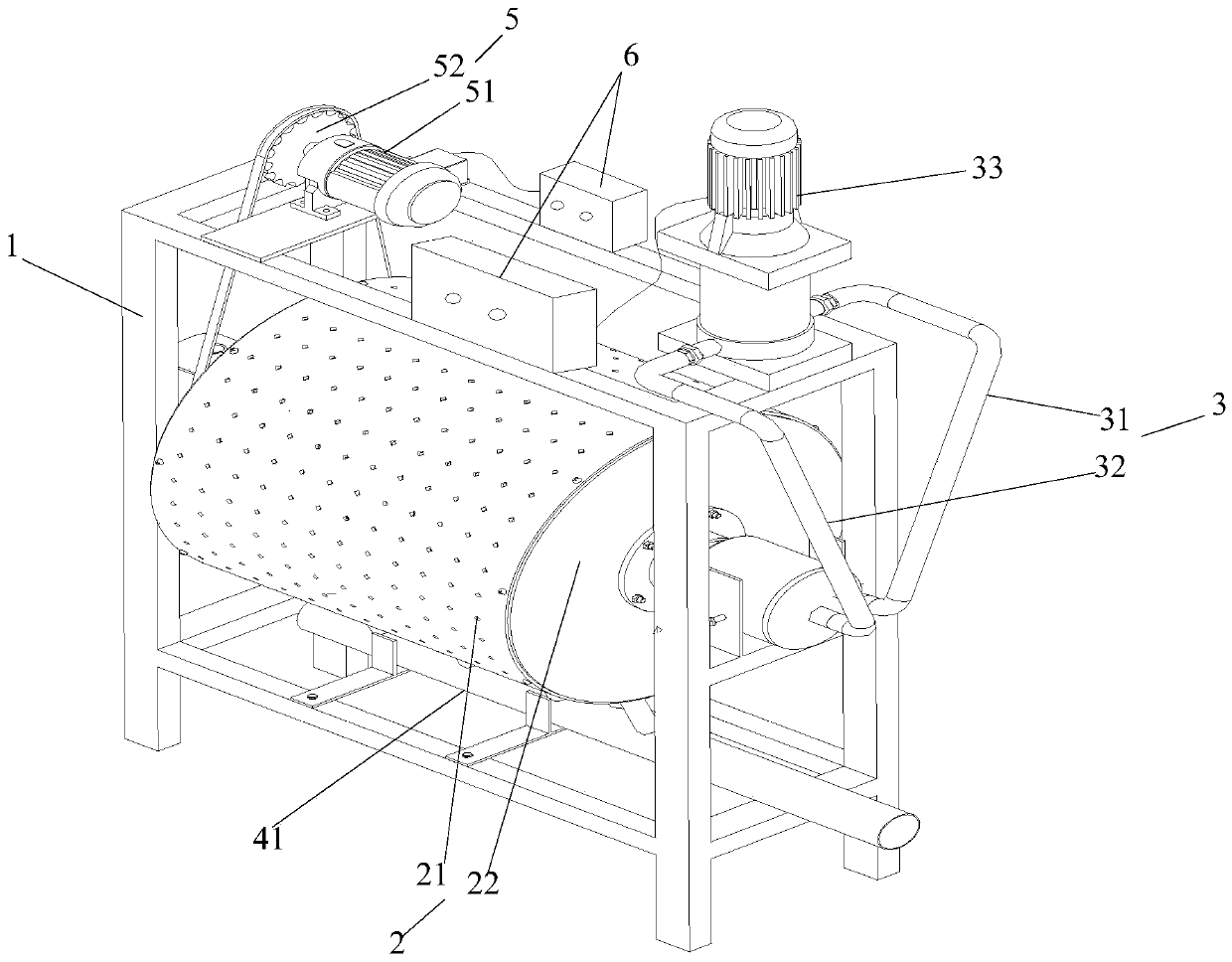

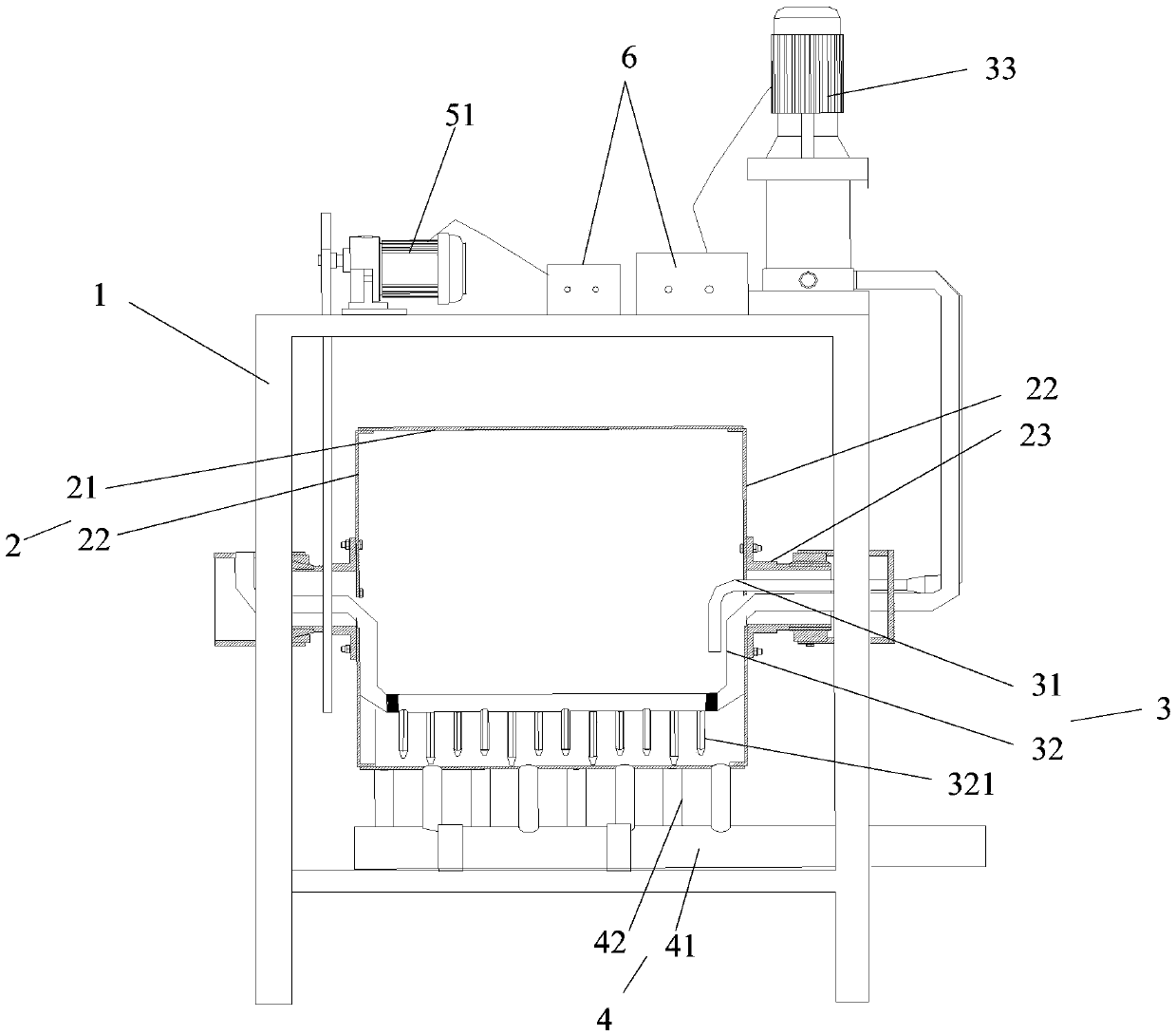

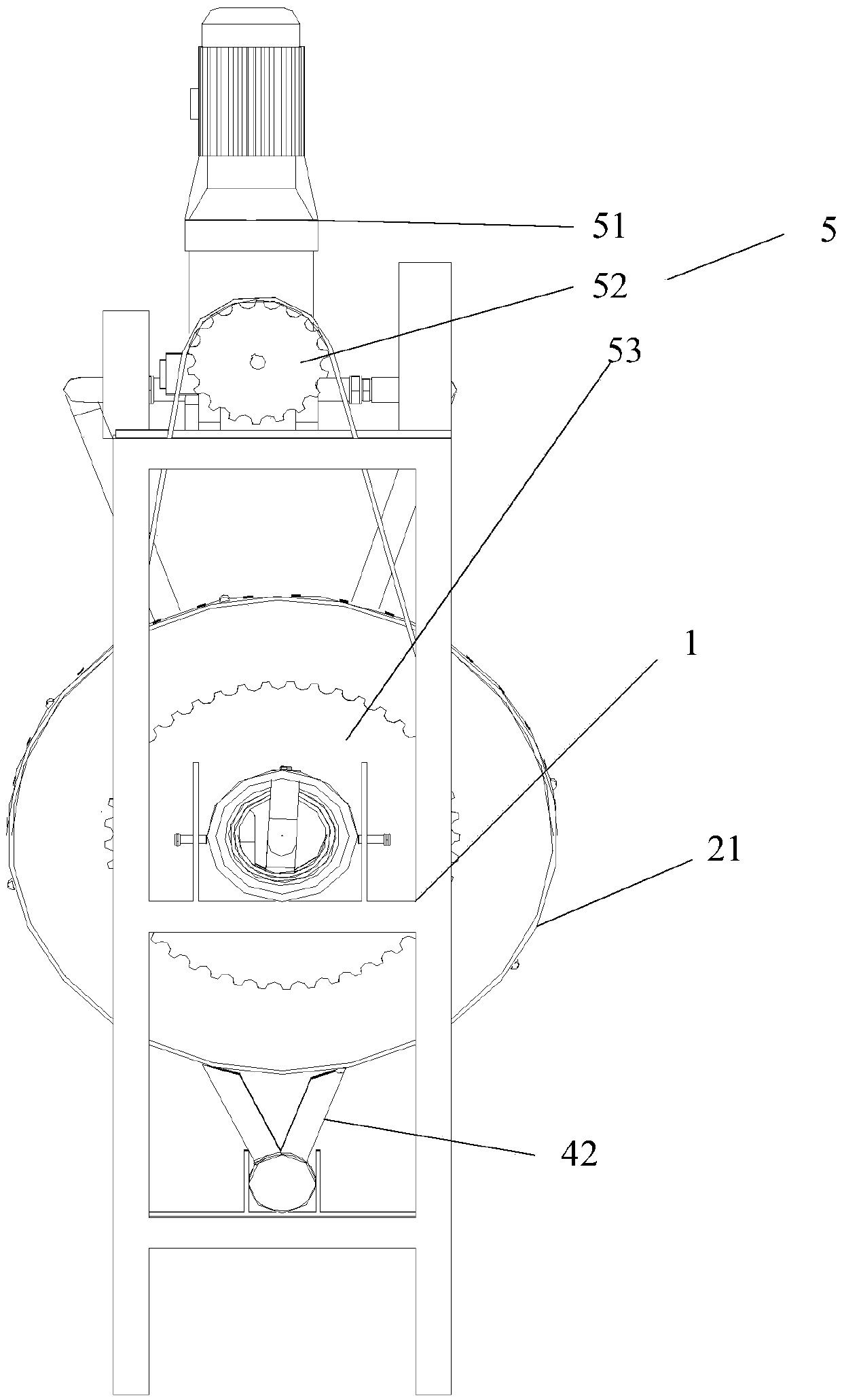

[0030] Such as figure 1 and 2 As shown, a kind of filter that the embodiment of the present invention proposes, it comprises: Frame 1, filter screen cylinder 2, backwash device 3 and blowdown device 4, filter screen cylinder 2 comprises bucket type filter screen 21 and two end seals The water cover 22 and the filter cylinder 2 are installed on the frame 1 through the rotating shaft 23; the backwash device 3 includes a recoil water intake pipe 31 and a recoil outlet pipe 32, and the water intake of the recoil intake pipe 31 is arranged inside the filter cylinder 2 , the recoil outlet pipe 32 stretches into the filter screen cylinder 2, and the water outlet of the recoil outlet pipe 32 has a predetermined distance from the bottom of the filter screen cylinder 2 inner surface; A group of dirt suction nozzles 42, the dirt suction nozzles 42 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com