A dust removal device

A technology of dust removal device and water tank, applied in separation device, combined device, dispersed particle separation and other directions, can solve the problems of expensive equipment manufacturing, large workload of dust removal, and cure the symptoms but not the root cause, so as to achieve easy maintenance, improve the purification effect, and improve the The effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

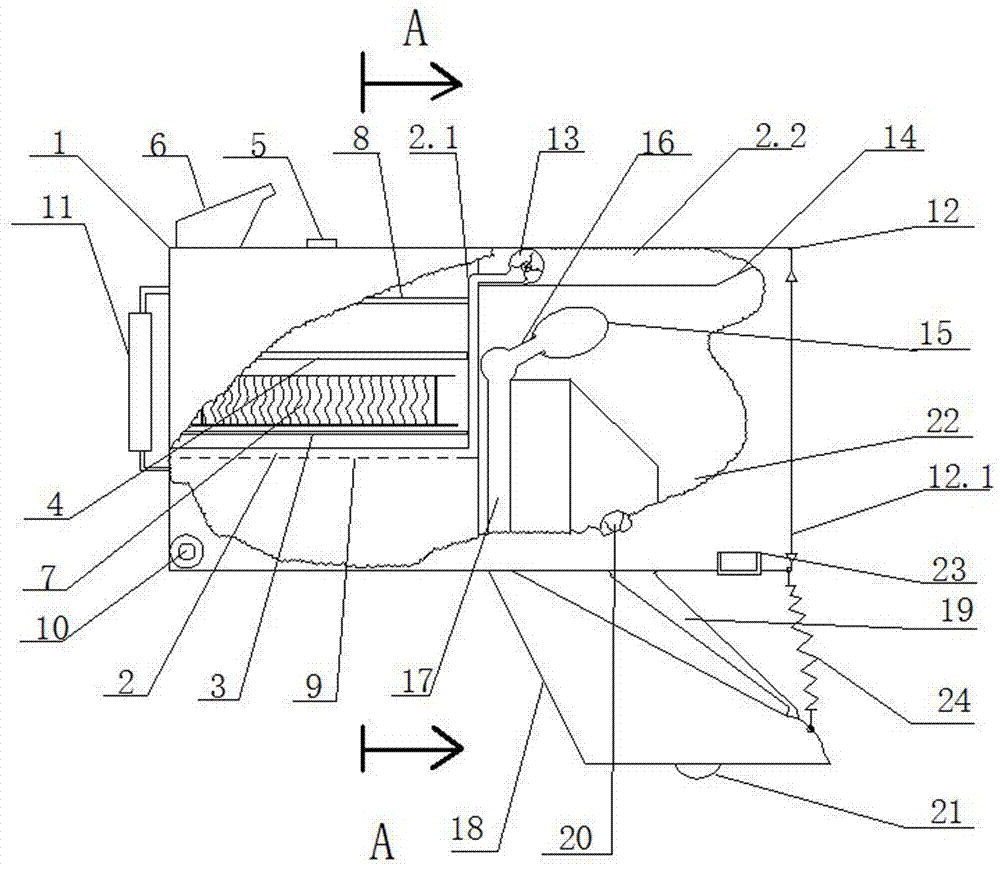

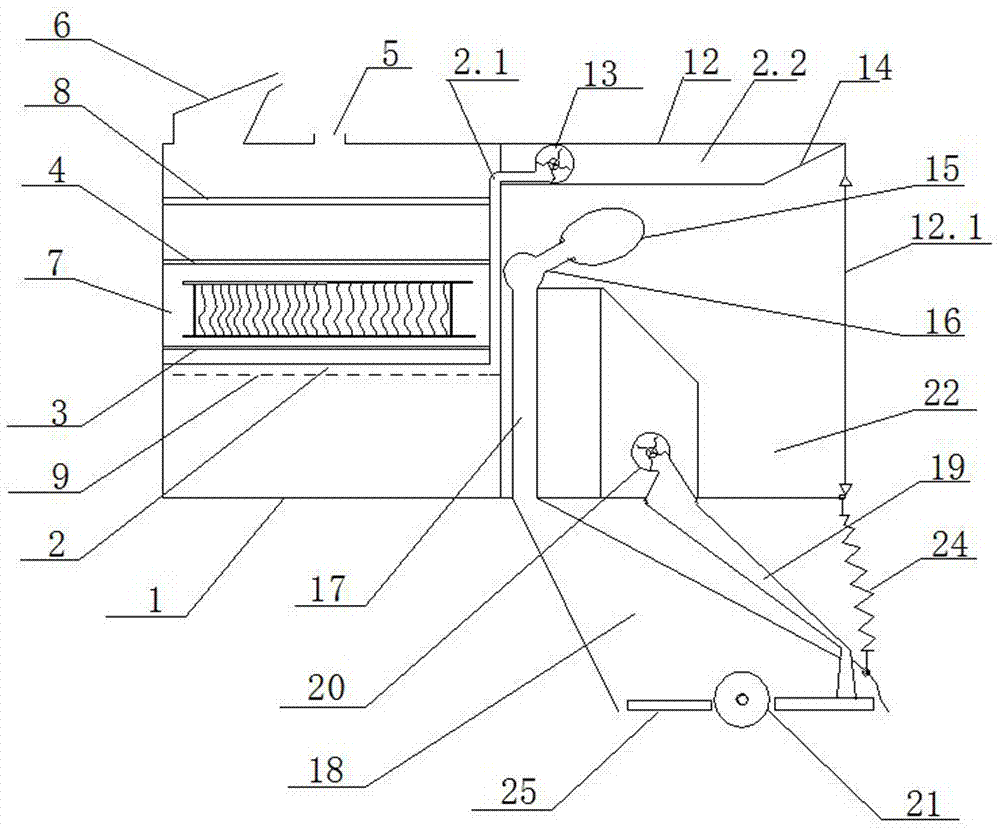

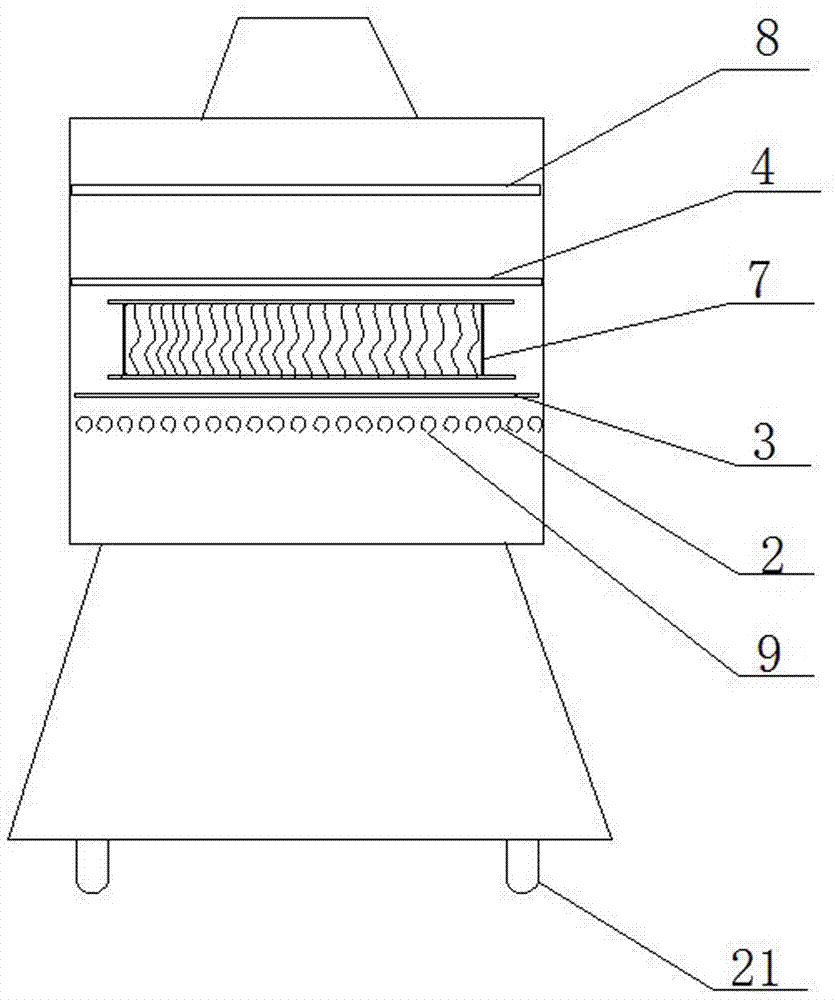

[0023] Combined with the manual Figure 1-5 , the dust removal device includes a water tank 1, an air distribution pipe 2, an air intake pipe 2.1, an air distribution net 3, an air flow sieve plate 4, a sewage outlet 10, a water injection port 5 and an exhaust port 6, and the water tank 1 is provided with an exhaust port 6 and a water injection port 5. The lower part of the water tank 1 is provided with a sewage outlet 10, one end of the air intake pipe 2.1 is connected to the air distribution pipe 2, and the other end extends out of the upper part of the outer side of the water tank 1, and the water tank 1 is sequentially provided with the air distribution pipe 2, the air distribution network 3 and the air flow The sieve plate 4 and the air distribution pipe 2 are arranged in a row, and the air distribution pipe 2 is provided with a diffuser hole 9 connected with the air distribution pipe 2. The sieve plate 4 is flexibly connected to the water tank 1.

[0024] The air flow s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com