Belly expansion detecting device of crank slide block type multi-bin pipe mill and belly pre-expansion control method

A technology of crank slider and detection device, which is applied in the direction of grain processing, etc., can solve problems such as the fluctuation of ore concentration and fineness, affect the production efficiency of tube mills, and destroy the stable operation of grinding, so as to achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

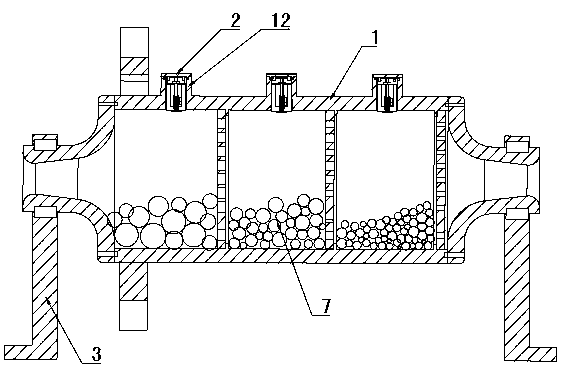

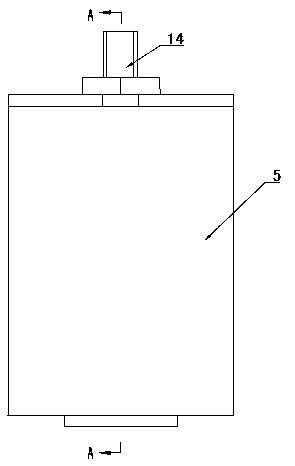

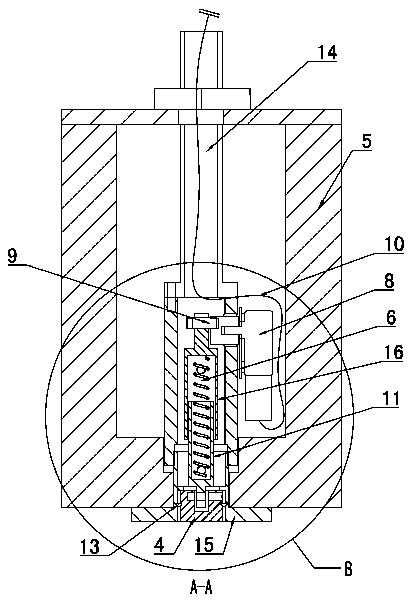

[0037] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0038] Refer to attached Figure 1-4 : Crank-slider type multi-chamber tube mill bulge detection device, crank-slider type multi-chamber tube mill bulge detection device, including the detection port 12 opened on the tube mill casing 1, the detection port 12 is outward Protruding cylindrical holes, each chamber of the tube mill is equipped with a detection port 12, the tube mill is supported and installed by the bracket 3 and driven to rotate by the frequency conversion generator, the tube mill is also equipped with a fan and a mineral conveying belt , the fan and the mineral conveying belt are controlled by the control system, and it is characterized in that: the upper part of the detection port 12 is sealed by the top cover 2 of the tube mill, and a detection device is installed in the detection port 12, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com