Pushing motor type swelling detecting device for compound tube mill and pre-swelling control method

A detection device, the technology of tube mill, which is applied in the direction of grain processing, etc., can solve the fluctuation of ore concentration and fineness, tube mill, sand return box of ore feeder, bearing gear damage, affecting the production efficiency of tube mill, etc. problem, to achieve the effect of improving the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

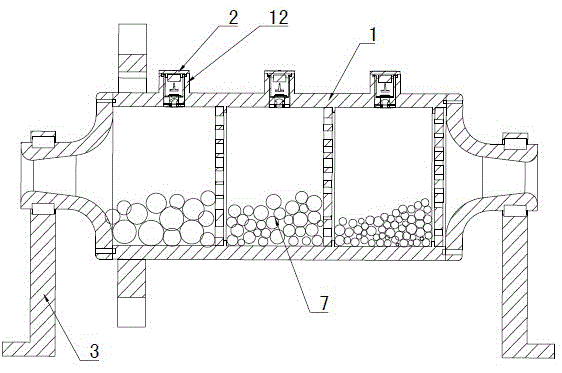

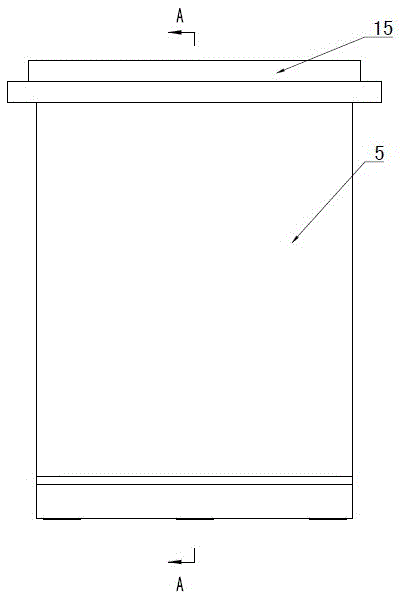

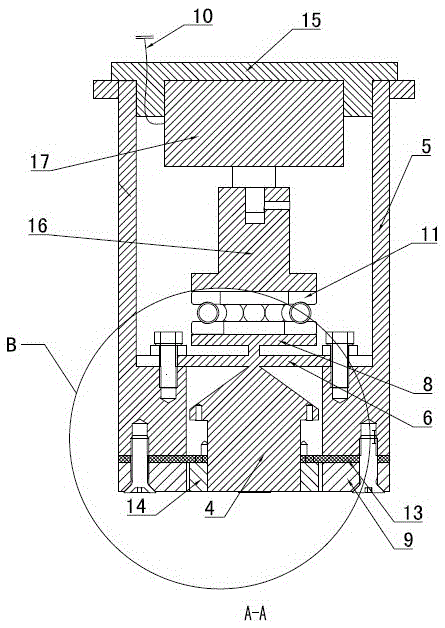

[0038] Figure 1~4 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~4 The present invention will be further described.

[0039] Refer to attached Figure 1-4 : Thrust motor type multi-chamber tube mill expansion belly detection device, including the detection port 12 opened on the tube mill casing 1, the detection port 12 is a cylindrical hole protruding outward, and each chamber of the tube mill corresponds to There is a detection port 12. The tube mill is supported and installed by a bracket 3 and driven to rotate by a frequency conversion motor. The tube mill is also equipped with a fan and a mineral conveying belt, both of which are controlled by the control system. The upper part of the detection port 12 is sealed by the top cover 2 of the tube mill. A detection device is installed in the detection port 12. The detection device includes a hollow cylinder 5. The upper circumference of the hollow cylinder 5 is installed in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com