Method for adjusting secondary cooling water amount and roll gap value of double-flow slab casting machine

The invention relates to a slab continuous casting machine and a technology of secondary cooling specific water volume, which is applied in the field of slab continuous casting and can solve the problems of reducing the mechanical properties and corrosion resistance of products, reducing the qualified rate of medium and thick plate flaw detection, and affecting the processing and service performance of steel. , to optimize the low magnification structure, reduce the incidence of cracks, and prevent bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Example 1: Low-alloy aluminum-controlled steel

[0033] Steel type: Q345R;

[0034] Pouring molten steel composition: C0.17%-Si0.33%-Mn1.44%-P0.017%-S0.002%-Alt0.034%;

[0035] Ladle temperature: 1567°C; Tundish temperature: 1530°C;

[0036] Casting speed: 0.95m / min; Section: 210mm×1500mm; Solidification process billet density according to 7400kg / m 3 .

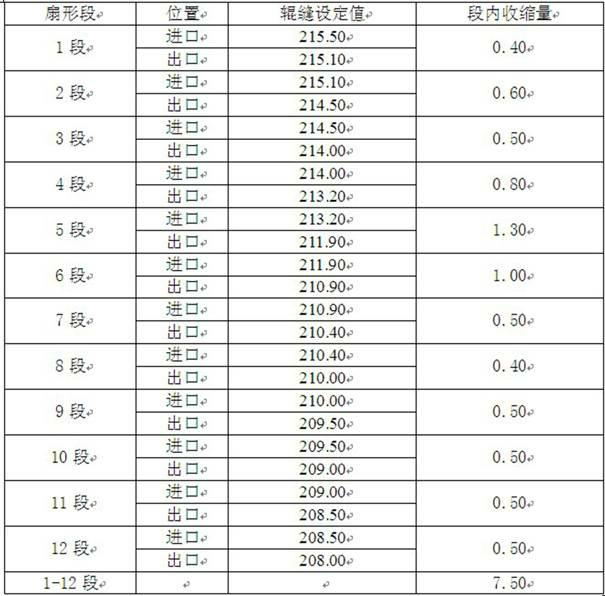

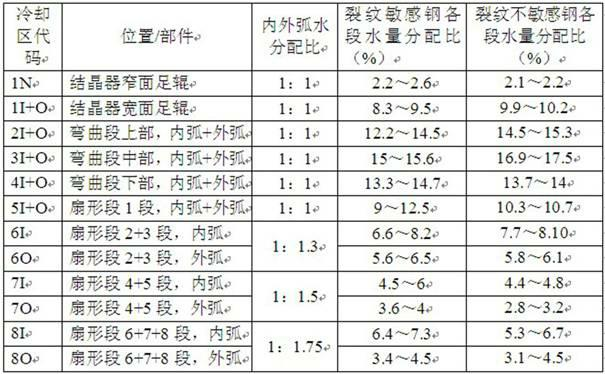

[0037] Water meter: 8# (specific water volume 0.50L / kg); Mold powder: AY-B

[0038] Table 2 Cooling water volume in each cooling zone of 8# water meter (drawing speed 0.95m / min, section 210mm×1500mm)

[0039] Cooling Zone Code location / part cooling form Cooling water volume (L / min) 1N Crystallizer narrow face foot roll spray water 26.0 1I+O Crystallizer Wide Face Roller spray water 96.0 2I+O The upper part of the curved section, inner arc+outer arc mist cooling 142.0 3I+O Middle part of the curved section, inner arc+outer arc mist cooling 181.0 4I+O The lo...

example 2

[0044] Example 2: plain carbon steel

[0045] Steel type: Q235B;

[0046] Pouring molten steel composition: C0.17%-Si0.18%-Mn0.44%-P0.018%-S0.009%;

[0047] Ladle temperature: 1577°C; Tundish temperature: 1540°C;

[0048] Casting speed: 0.9m / min; Section: 230mm×1500mm; Solidification process billet density is 7400kg / m 3 ;

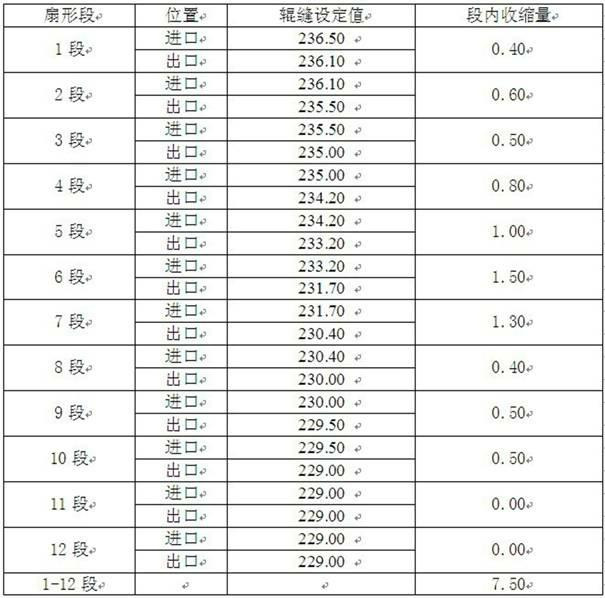

[0049] Water meter: 4# (specific water volume 1.10L / kg); Mold flux: BY-2.

[0050] Table 4 Cooling water volume in each cooling zone of 4# water meter (drawing speed 0.9m / min, section 230mm×1500mm)

[0051] Cooling Zone Code location / part cooling form Cooling water volume (L / min) 1N Crystallizer narrow face foot roll spray water 56.0 1I+O Crystallizer Wide Face Roller spray water 256.0 2I+O The upper part of the curved section, inner arc+outer arc mist cooling 381.0 3I+O Middle part of the curved section, inner arc+outer arc mist cooling 436.0 4I+O The lower part of the curved section, inner a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com