Electrolyte for lithium ion batteries and lithium ion battery containing same

A lithium-ion battery, electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., to achieve the effect of preventing gas swelling, good cycle performance, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

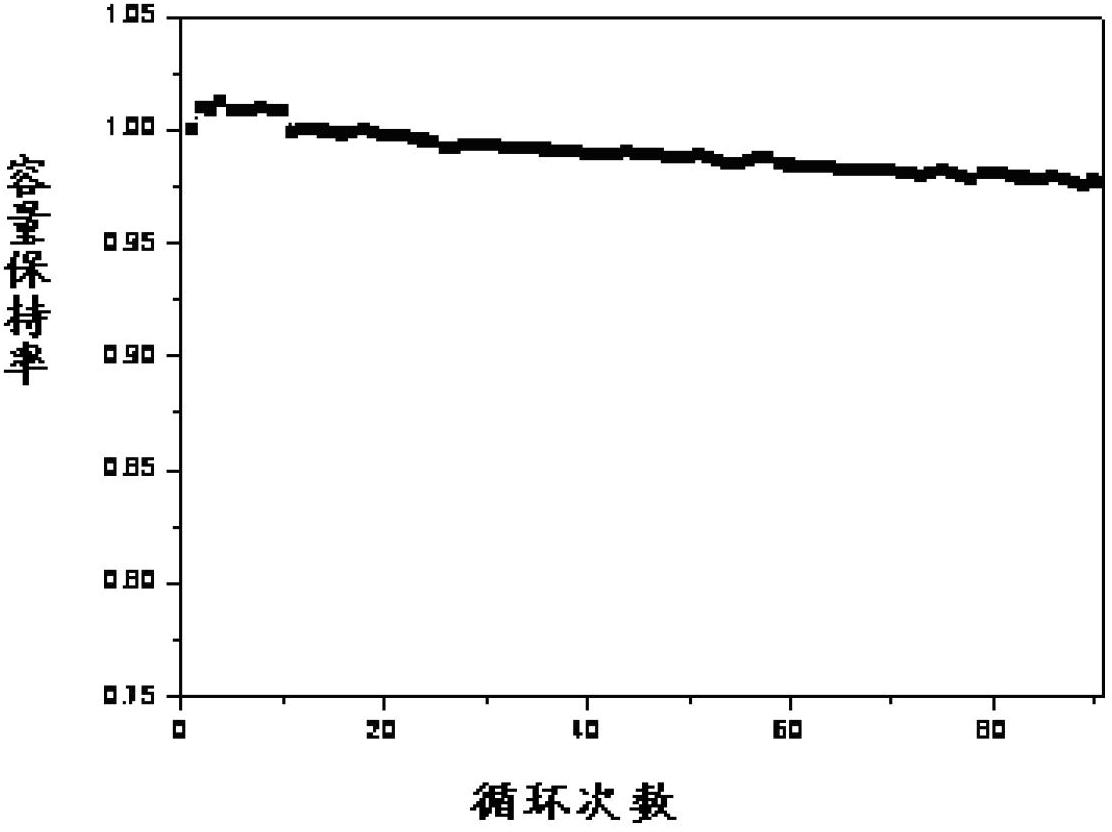

Embodiment 1

[0043] This embodiment provides a lithium ion battery.

[0044] The composition of the positive electrode material of the lithium-ion battery (based on the mass fraction of the positive electrode material as 100%): 91% LiNi 0.5 mn 1.5 o 4 , 4% of small particles of conductive carbon black, 5% of polyvinylidene fluoride.

[0045] The composition of the negative electrode material of the lithium-ion battery (based on the mass fraction of the negative electrode material as 100%): 88% silicon-based alloy (Si-C), 2% small particle conductive carbon black and 2% large particle graphite powder, 8 % polyacrylic acid.

[0046] The composition of the electrolyte (the sum of the mass of the solvent and additives is 100%): the solvent is: 30% ethylene carbonate (EC), 30% diethyl carbonate (DEC), 35% fluoroethylene carbonate Ester (FEC);

[0047] The additives are: 2% ethylene sulfate (DTD) and 3% propylene sulfite (PS);

[0048] The electrolyte salt is: lithium hexafluorophosphate L...

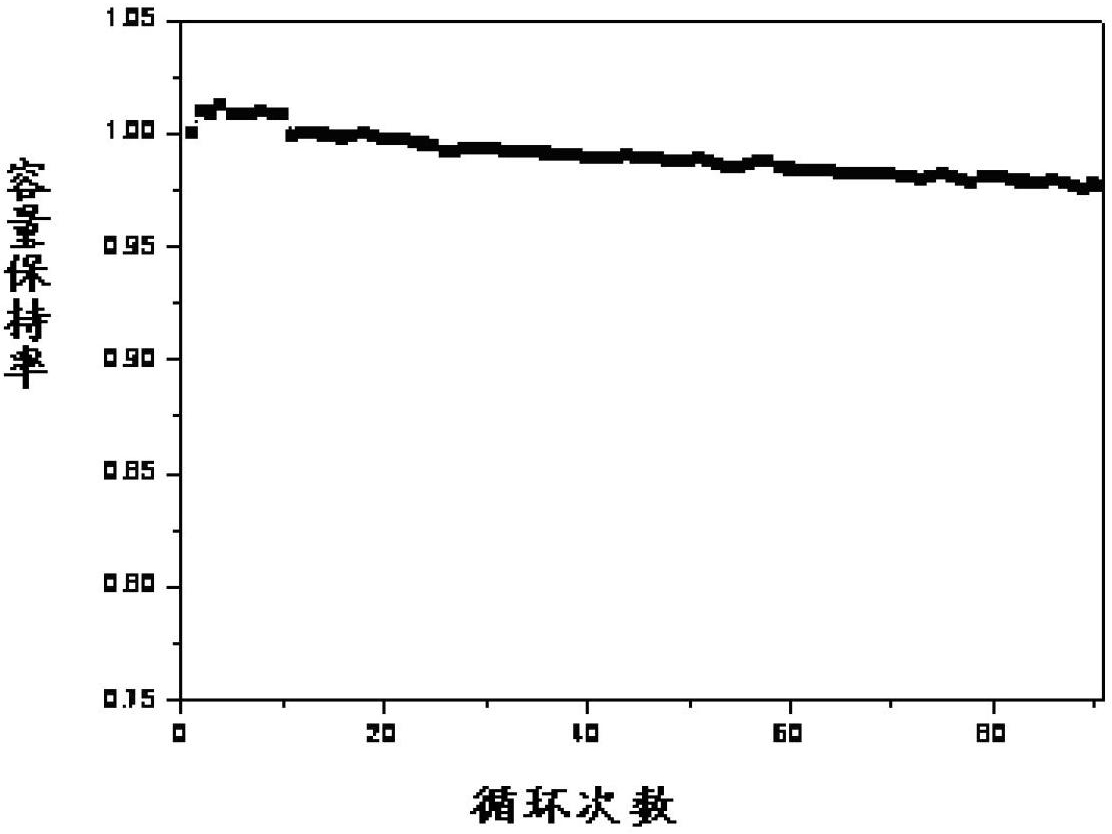

Embodiment 2

[0058] This embodiment provides a lithium ion battery.

[0059] The composition of the positive electrode material of the lithium-ion battery (based on the mass fraction of the positive electrode material as 100%): 94% LiNi 0.5 mn 1.5 o 4 , 2% carbon fiber, 4% polyvinylidene fluoride.

[0060] The composition of the negative electrode material of the lithium-ion battery (based on the mass fraction of the negative electrode material as 100%): 92% silicon-based alloy (Si-C), 4% large particle graphite powder, and 4% polyacrylic acid.

[0061] The composition of the electrolyte (based on the sum of the mass of the solvent and additives as 100%): the solvent is: 40% diethyl carbonate (DEC), 53% ethyl methyl carbonate (EMC) 35-40;

[0062] The additives are: 5% ethylene sulfate (DTD) and 5% propylene sulfite (PS);

[0063] The electrolyte salt is: lithium hexafluorophosphate LiPF 6 , the concentration of the substance in the electrolyte is 1.2mol / L.

[0064] The preparation m...

Embodiment 3

[0068] This embodiment provides a lithium ion battery.

[0069] The composition of the positive electrode material of the lithium-ion battery (based on the mass fraction of the positive electrode material as 100%): 93% LiNi 0.5 mn 1.5 o 4 , 3% carbon nanotubes, 4% polyvinylidene fluoride.

[0070] The composition of the negative electrode material of the lithium-ion battery (based on the mass fraction of the negative electrode material as 100%): 90% silicon-based alloy (Si-C), 3% small particle conductive carbon black, and 6% polyacrylic acid.

[0071] The composition of the electrolyte (based on the sum of the mass of the solvent and additives as 100%): the solvent is: 25% diethyl carbonate (DEC), 30% ethyl methyl carbonate (EMC), 35% Fluoroethylene carbonate (FEC);

[0072] The additive is: 7% ethylene sulfate (DTD);

[0073] The electrolyte salt is: lithium hexafluorophosphate LiPF 6 Lithium dioxalate borate LiBOB, Lithium hexafluorophosphate LiPF 6 The substance con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com