Equipment system for processing and utilization of low-grade sandstone

A low-grade, sandstone technology, applied in grain processing and other directions, can solve the problems of waste, ineffective utilization, waste of resources, etc., and achieve the effect of simple system, convenient use and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

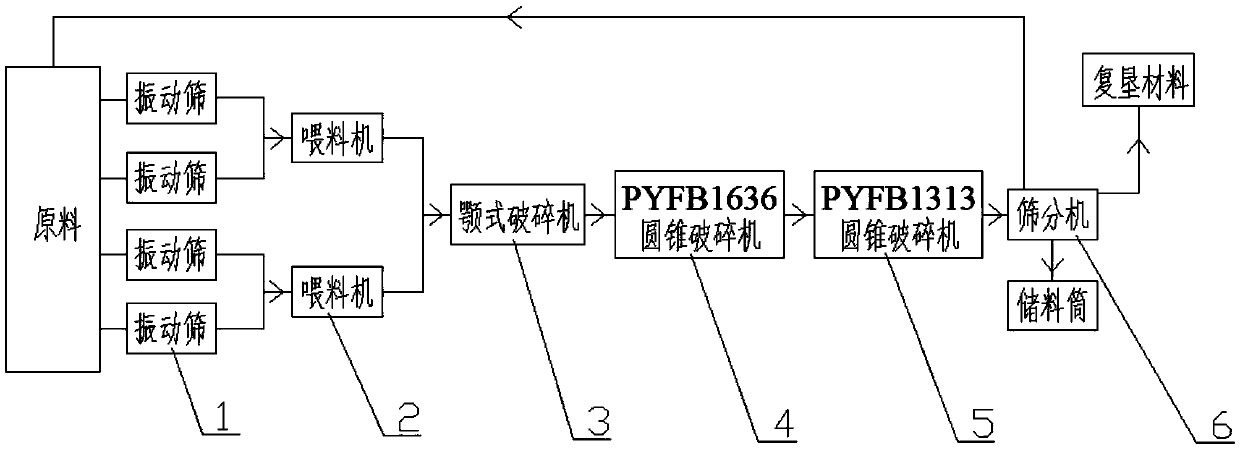

[0012] see figure 1 , an equipment system for low-grade sandstone processing and utilization provided by the present invention, comprising a vibrating screen 1, a feeder 2, a jaw crusher 3, a PYFB1636 cone crusher 4, and a PYFB1313 cone crusher 5 connected in sequence And the screening machine 6, the coarse material outlet of the screening machine 6 is connected to the raw material gathering place at the front end of the vibrating screen 1, and the material collection place for land reclamation, and the fine material outlet of the screening machine 6 is connected to the fine material storage barrel.

[0013] A method for processing and utilizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com