Ejection fixing device for milling

A fixing device and milling technology, applied in metal processing equipment, turning equipment, manufacturing tools, etc., can solve the problems of large volume, high machining accuracy and high use cost of automatic fixtures, and achieve simple and compact structure, low machining accuracy requirements, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

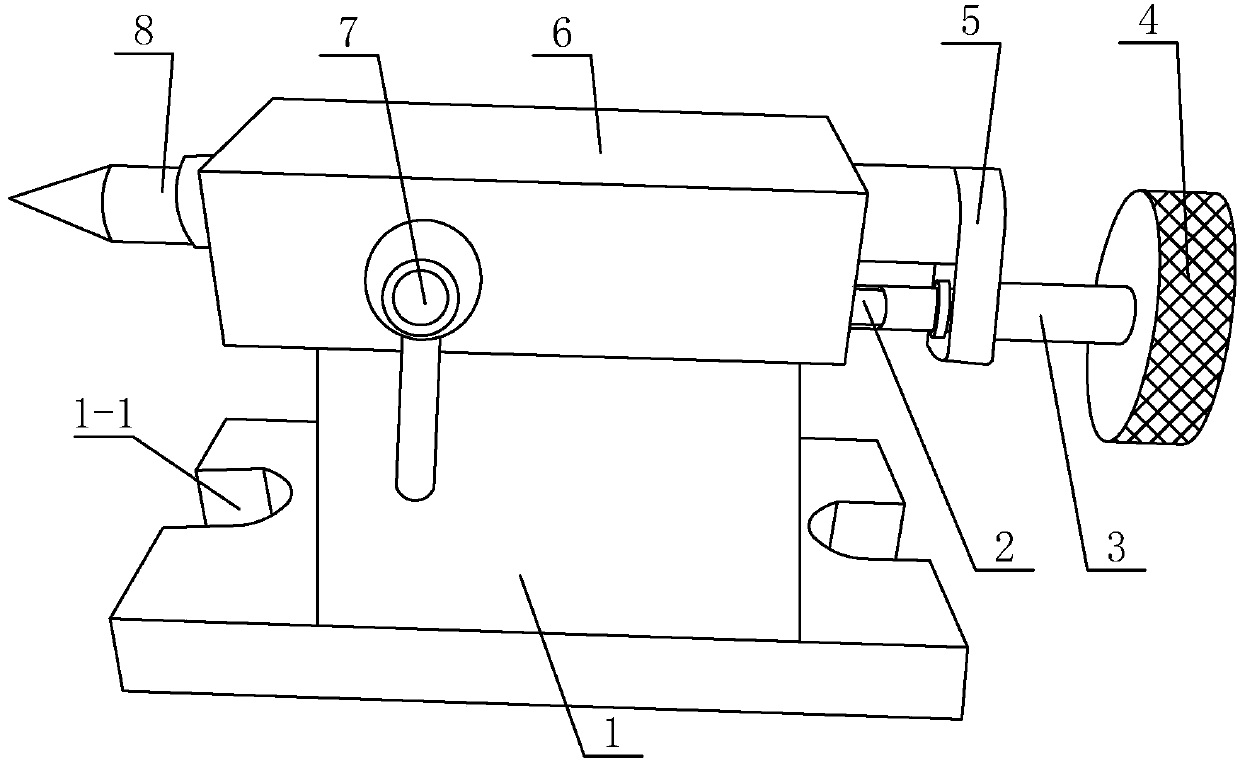

[0020] Such as figure 1 A clamping and fixing device for milling is shown, which includes a mounting base 1 that acts as a fixed support, and also includes a sliding top 8 for clamping the workpiece to be processed and a screw 2 for providing driving force; the mounting base 1 A support 6 is fixedly installed on the upper side, the sliding center 8 is slidably installed in the support 6 through a light hole, and the screw parallel to the sliding center 8 is installed in the support 6 through a threaded hole 2. The tail end of the sliding top 8 is fixedly connected to the upper end of the connecting piece 5, the lower end of the connecting piece 5 is rotatably connected to the rotating shaft 3, one end of the rotating shaft 3 is fixedly connected to the screw 2, and the other end of the rotating shaft 3 is fixedly installed There is a driving handle 4, and the outer peripheral surface of the driving handle 4 is provided with anilox knurling for increasing friction.

[0021] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com