Multi-head fit type polishing machine

A polishing machine and multi-head technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, grinding heads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

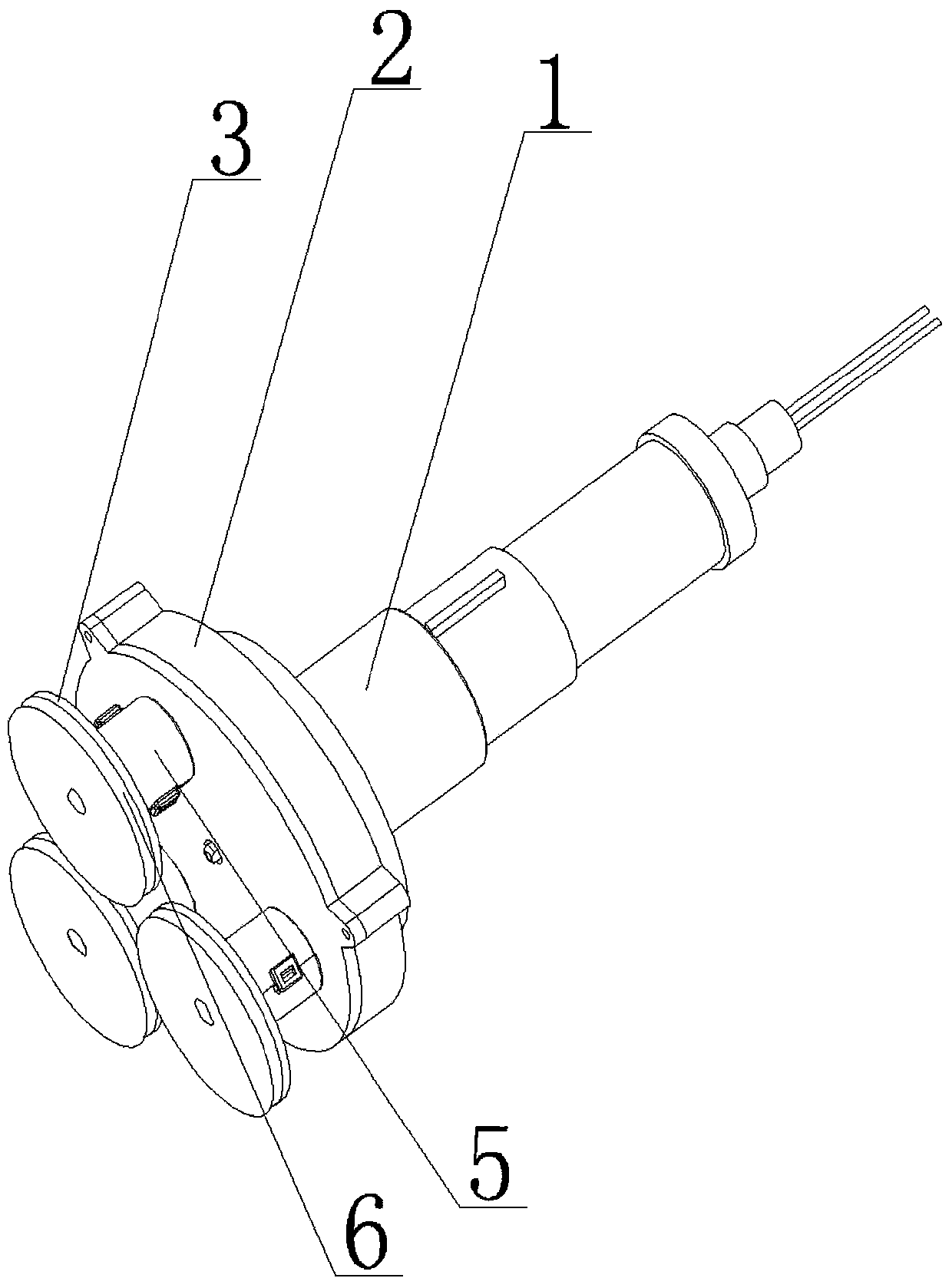

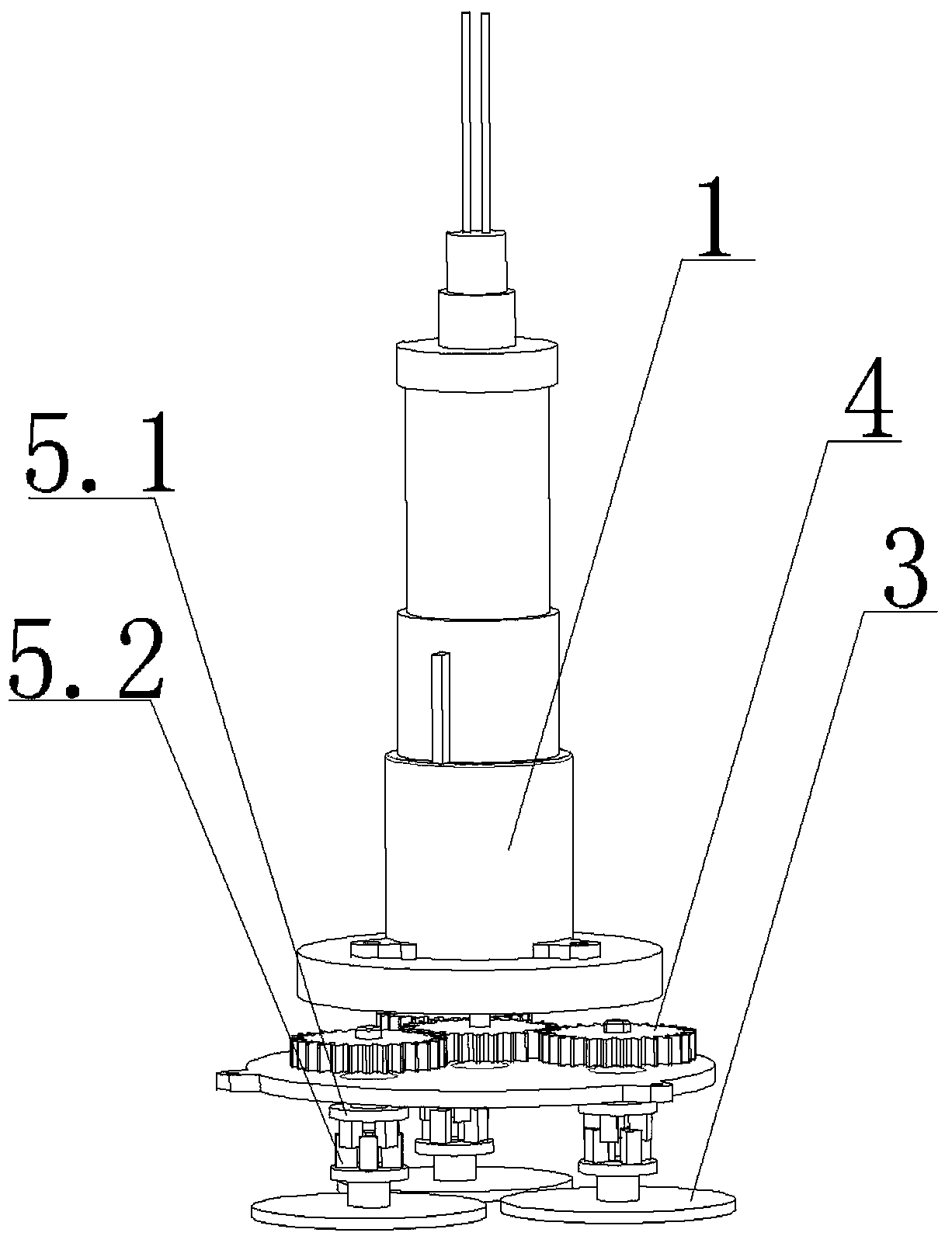

[0031] Such as figure 1 with 2 As shown, a multi-head bonding grinder includes a motor 1, a gear box 2, and at least two rotary tables 3. The gear box 2 is fixedly connected to the body of the motor 1, and a gear set is arranged inside the gear box 2. 4. The transmission shaft of the motor 1 is linked with the driving wheel of the gear set 4, and the rotary table 3 is connected and rotated with the driven wheel of the gear set 4; the number of the rotary table 3 is three.

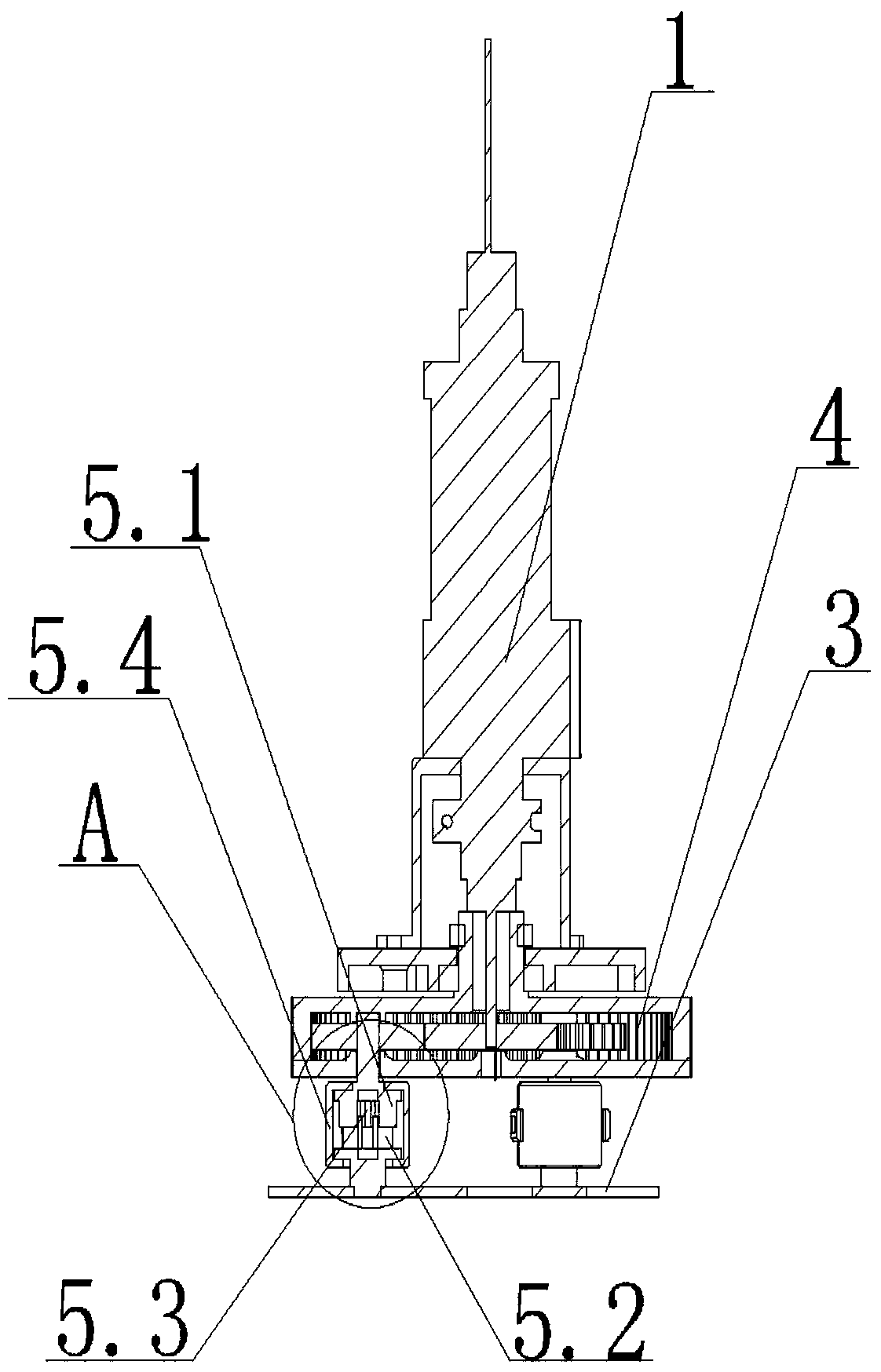

[0032] Such as figure 2 , 3 As shown in and 4, the rotation fit means that the multi-head lamination grinder also includes a connector 5, and the connector 5 includes a first connecting part 5.1, a second connecting part 5.2, an elastic part 5.3 and a buckle 5.4 , the first connecting piece 5.1 is linked with the driven wheel of the gear set 4, the second connecting piece 5.2 is engag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com