Mechanical fabricated part production machine

A technology for production machines and prefabricated parts, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of inability to meet product supply requirements, low production efficiency, and low strength, so as to ensure product appearance quality, improve labor productivity, and guarantee The effect of concrete strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

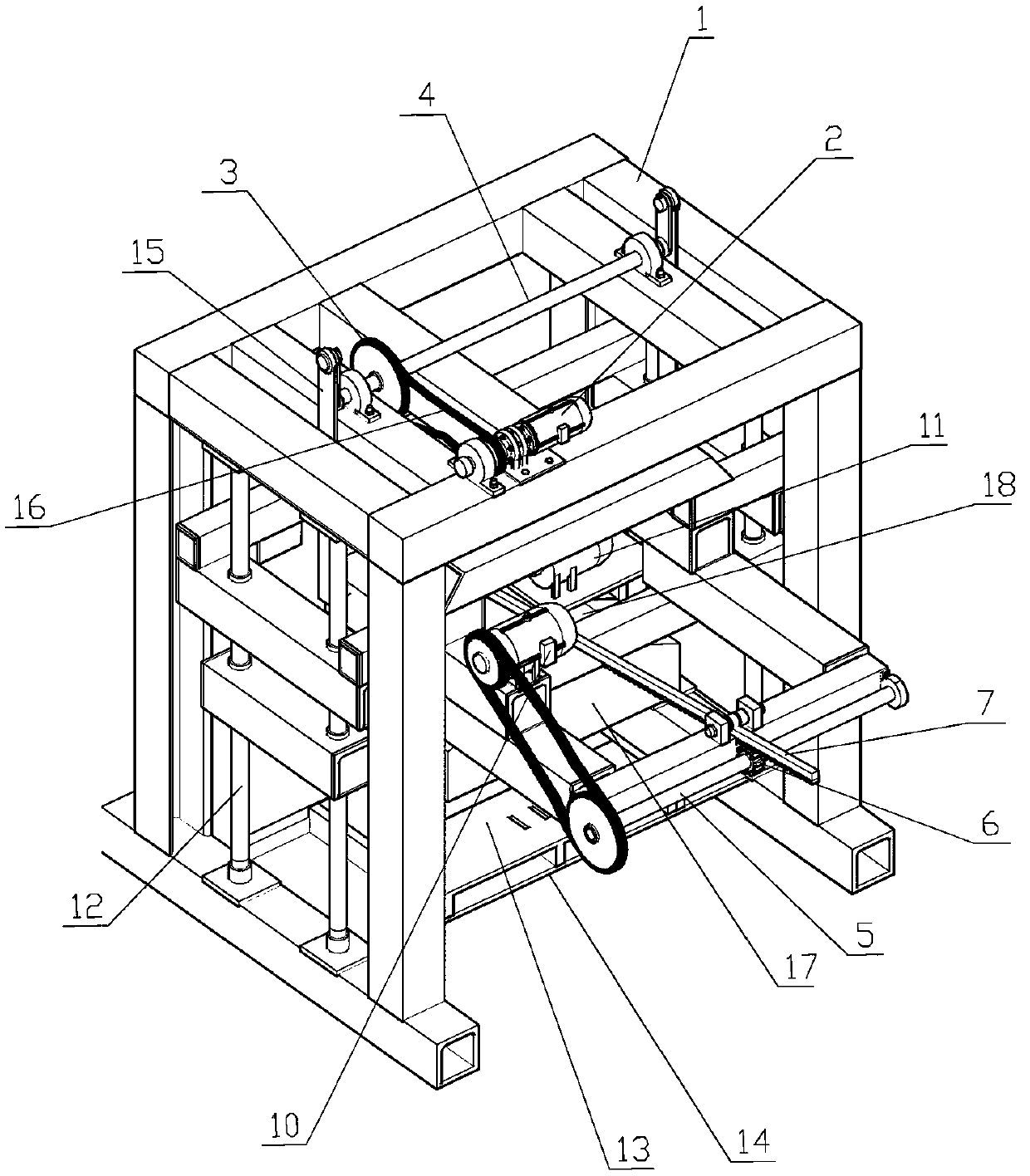

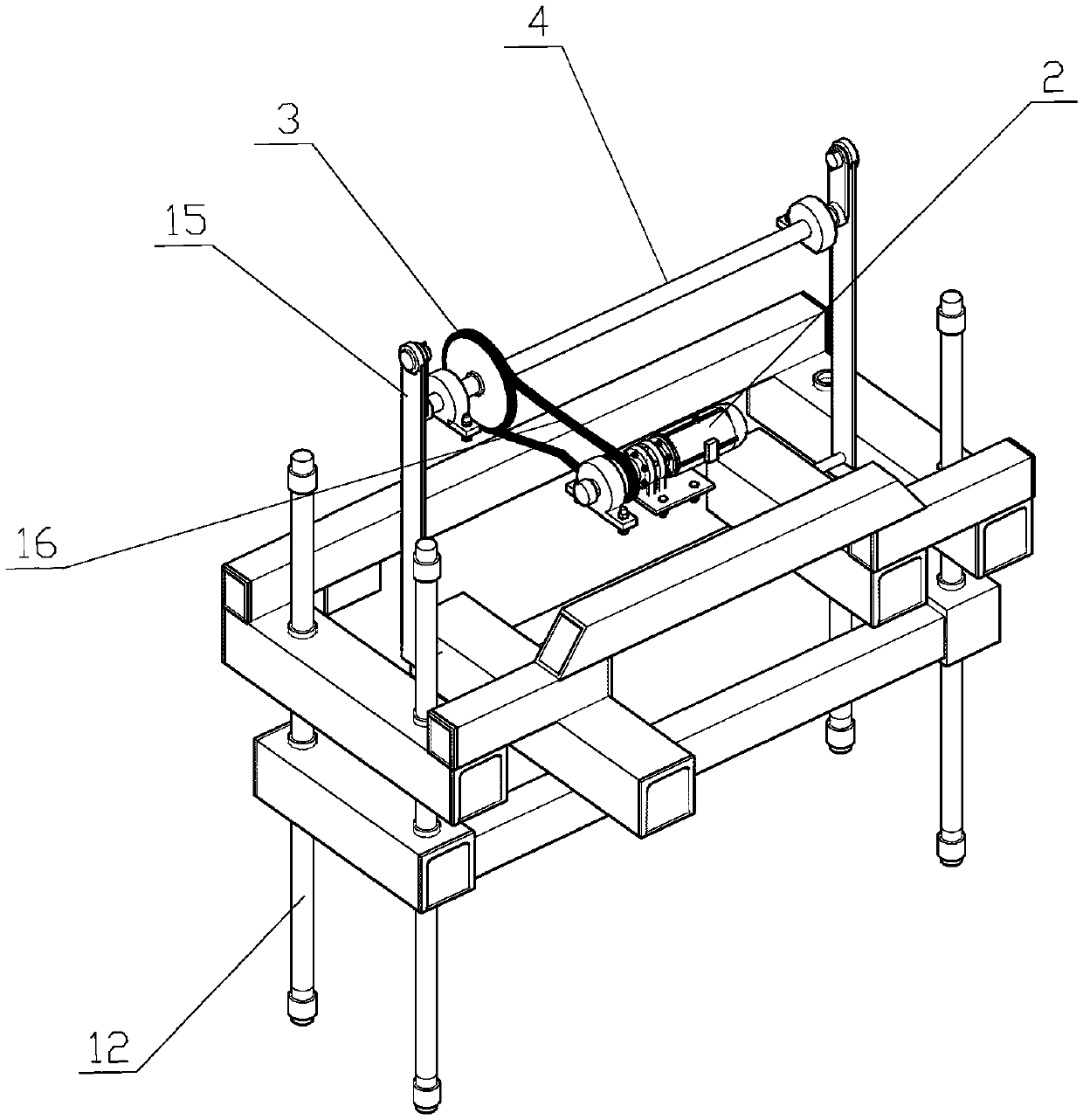

[0023] Such as figure 1 Among them, a mechanized preform production machine includes a lifting motor 2 arranged at the top of the frame 1, and a sliding rod 12 is arranged on the frame 1, such as figure 2 Among them, the support frame is set on the sliding rod 12, the lifting motor 2 drives the transmission gear 3 to rotate through the transmission chain 16, the transmission gear 3 drives the lifting gear transmission rod 4 to rotate, the lifting gear transmission rod 4 and the transmission rod 15 are connected through the rotating shaft, and the lifting motor 2 Drive the transmission gear 3 to rotate through the transmission chain 16, the rotation of the transmission gear 3 drives the rotation of the lifting gear transmission rod 4, and the rotation of the lifting gear transmission rod 4 drives the bracket to slide up and down along the sliding rod 12 through the rotation of the rotating shaft.

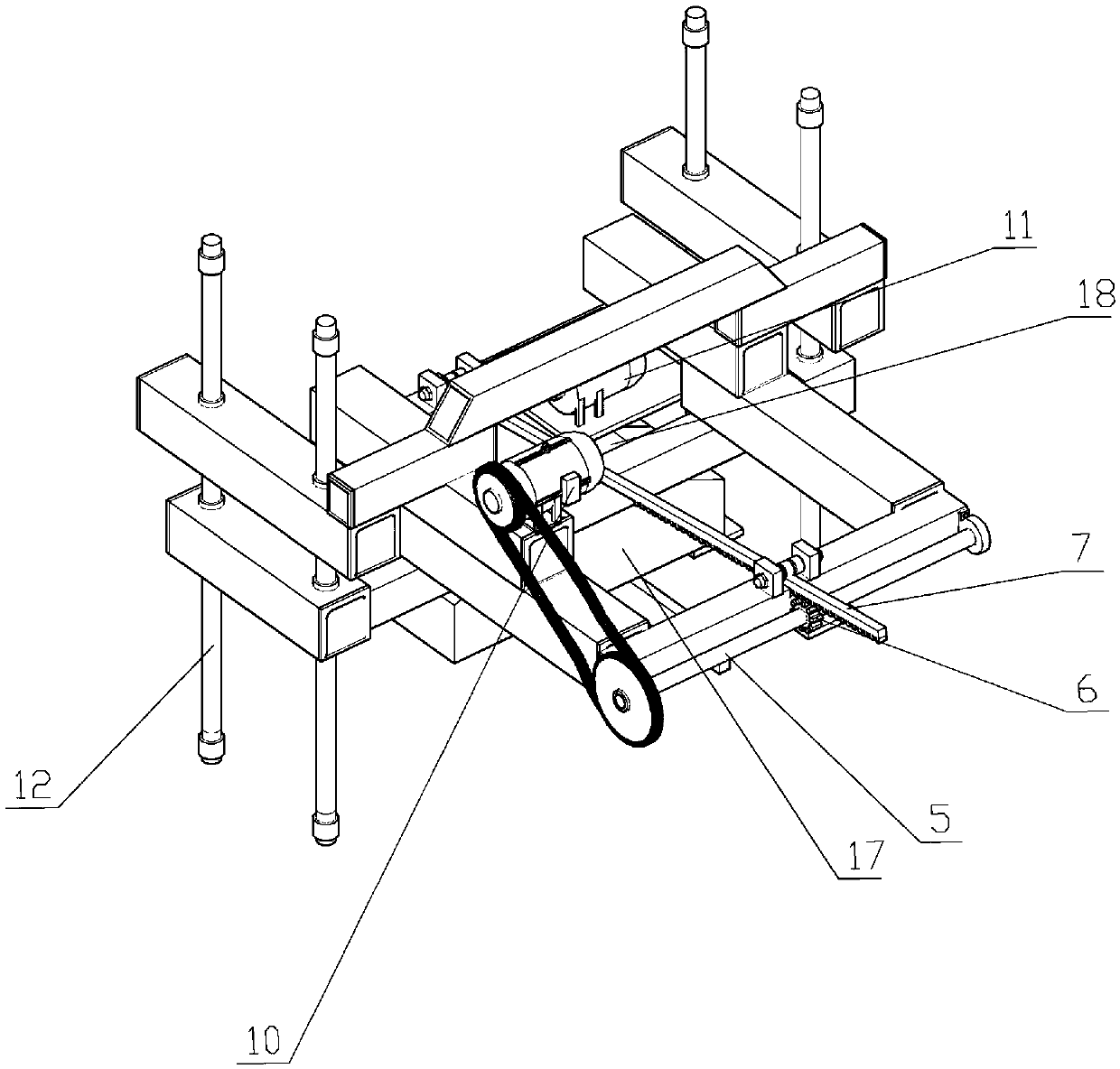

[0024] Such as image 3 Among them, a walking motor 10 is arranged on the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com