Brake apparatus

A brake device and brake shaft technology, which is applied to vehicle parts, transportation and packaging, passenger space, etc., can solve the problem of high labor intensity and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

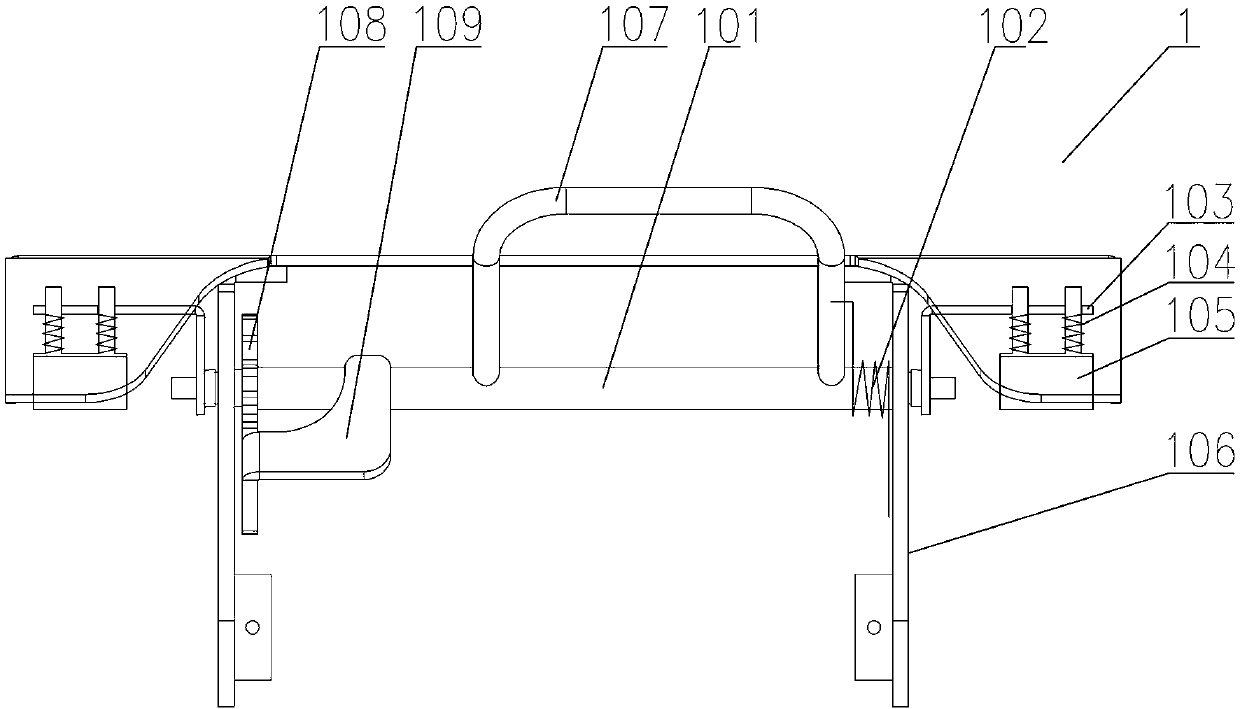

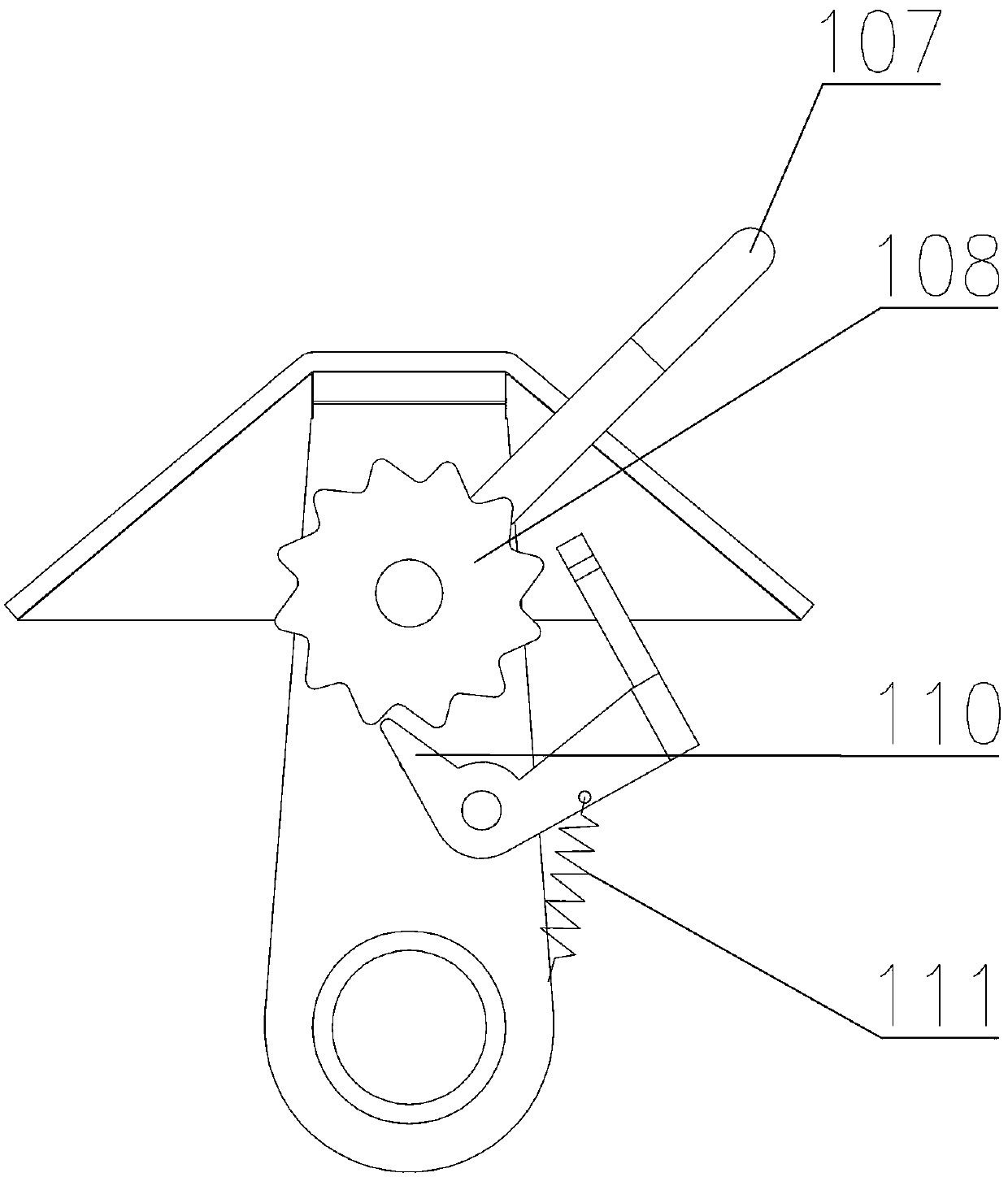

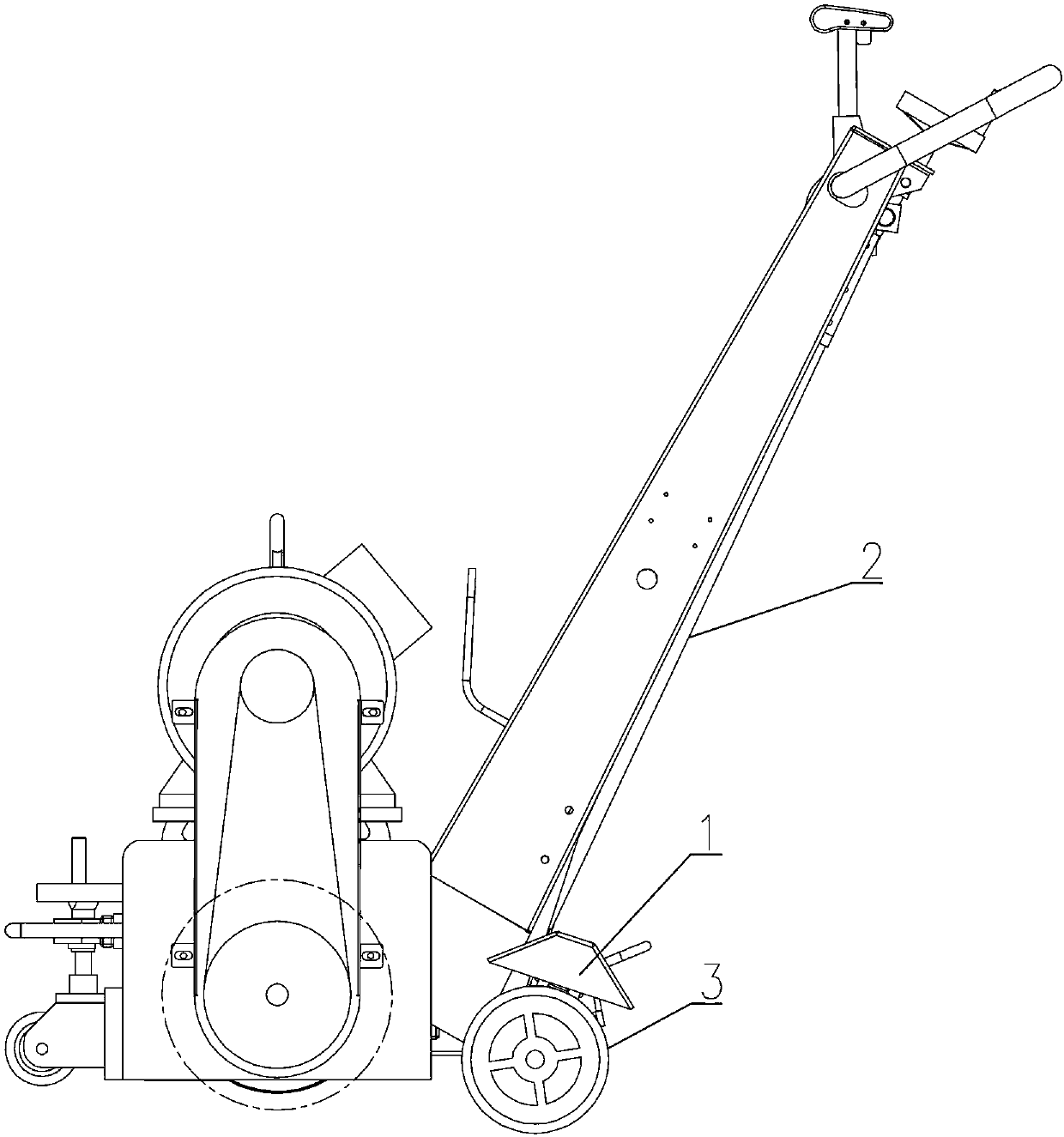

[0014] Such as Figure 1~3 Among them, in the brake device 1, the brake bracket 106 is fixedly connected with the milling machine 2, the brake shaft 101 is pivotally installed on the brake bracket 106, the brake shaft 101 is provided with a pressure handle 107, and the two ends of the brake shaft 101 pass through the brake The seat 103 is equipped with a brake pad 105, and the brake pad 105 is located above the traveling wheel 3;

[0015] A torsion spring 102 is provided between the brake shaft 101 and the brake bracket 106 to make the brake pad 105 tend to separate from the running wheel 3 . Due to the poor construction environment of some mechanical equipment, such as a milling machine, a structure such as a disc brake is easily affected by dust and becomes invalid. Therefore, the structure that directly rubs against the road wheel 3 is less affected by the environment. The brake pad 105 in this example is made of rubber. When in use, the brake pad 105 can be brought into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com