Walking hydraulic transmission system of hydraulic four-wheel-drive high-ground-clearance wheel type spraying machine

A technology of hydraulic transmission and high ground clearance, which is used in fluid pressure actuation system components, motor vehicles, fluid pressure actuation devices, etc., can solve the problems of narrow two-wheel drive application range, high horsepower output loss, and tight operation cycle time. Achieve a wide range of applications, effective transmission, and high horsepower output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

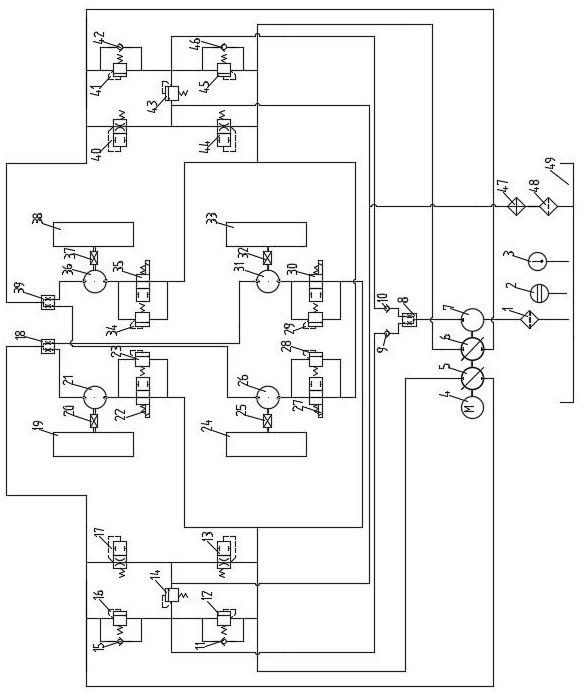

[0013] like figure 1 As shown in the figure, the walking hydraulic transmission system of the hydraulic four-wheel drive high ground clearance wheel sprayer includes a fuel tank 49, an engine 4, a first closed pump 5, a second closed pump 6, a quantitative pump 7, a first diverter valve 18, a first The second diverter valve 39 , the third diverter valve 8 , the left front wheel hydraulic motor 21 , the left rear wheel hydraulic motor 26 , the right front wheel hydraulic motor 36 , and the right rear wheel hydraulic motor 31 .

[0014] The output shaft of the engine 4 is connected to the first closed pump 5 , the second closed pump 6 and the quantitative pump 7 .

[0015] One oil port of the first closed pump 5 is connected to the oil collecting port of the first diverter valve 18, and one oil port of the first diverter valve 18 is connected to the oil port of the left front wheel hydraulic motor 21, and the left front wheel hydraulic motor 21 The other oil port is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com