Ceramic sanitary ware finished product grading automatic pipeline system

A sanitary ware and assembly line technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of easy damage and scratch damage rate, many four-wheel trolleys, high labor intensity, etc., to reduce labor and damage efficiency, reduce bruises, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

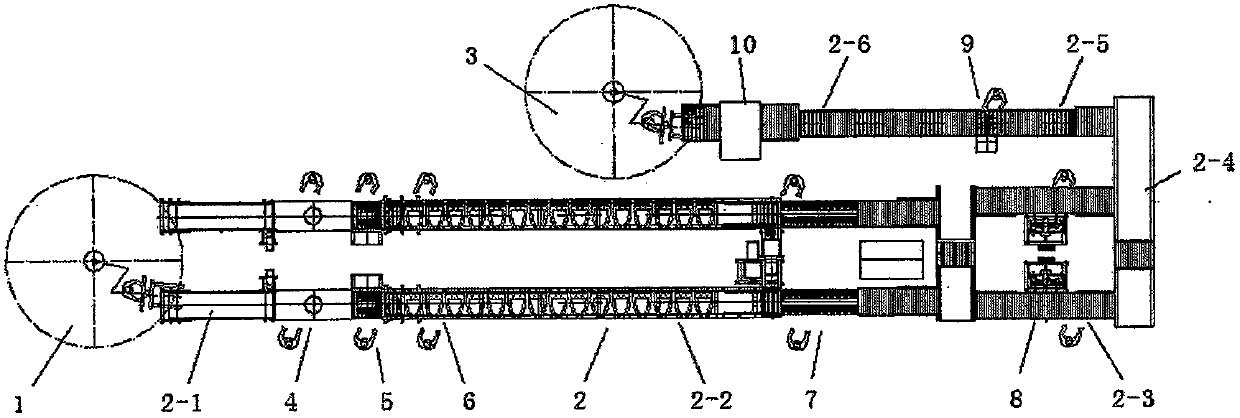

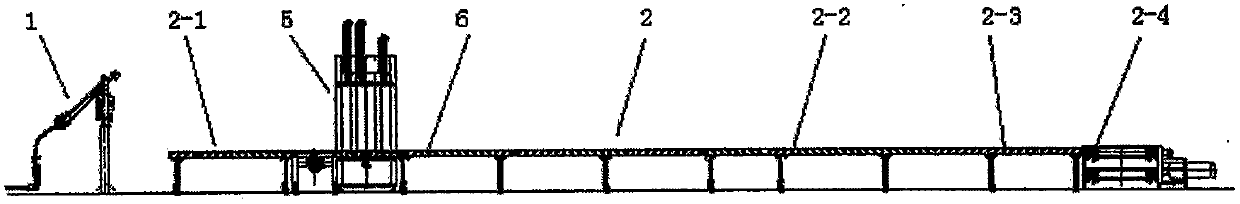

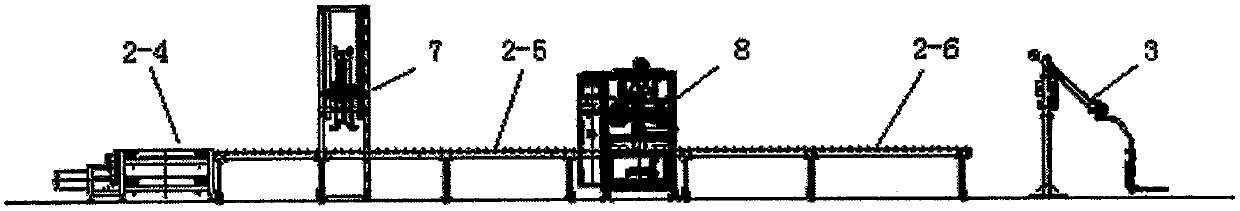

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] Such as figure 1 , figure 2 and image 3 As shown, an automatic assembly line system for classifying finished products of ceramic sanitary ware, including a finished product on-line booster arm 1, a conveying system 2 and an off-line booster arm 3, and the conveying system 2 is provided with an appearance inspection station 4 and a vacuum leak detector in sequence. 5. Water fittings installation 6. Water testing and drying station 7. Flip detection and repair device 8. Laser marking and boxing device 9 and automatic packaging machine 10; the appearance inspection station 4. Vacuum leak detector 5. Turnover detection and repair device 8, laser marking and packing device 9 and automatic packaging machine 10 are auxiliary detection equipment;

[0036] The conveying system 2 includes an upper line section 2-1, a transmission section 2-2, a detection an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com