Preparation method of high-strength magnesium Longquan celadon billet, glaze and product

A high-strength, celadon technology, applied to clay products, applications, household utensils, etc., can solve the problems of not achieving the aesthetic effect of Longquan kiln celadon, unfavorable production and application, and difficulty in firing thick-glazed celadon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

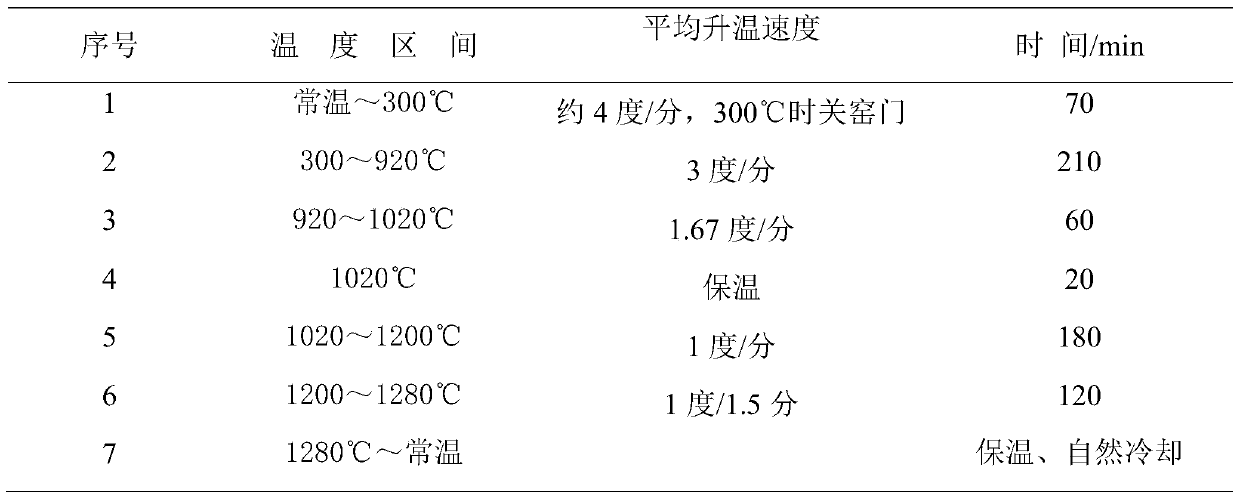

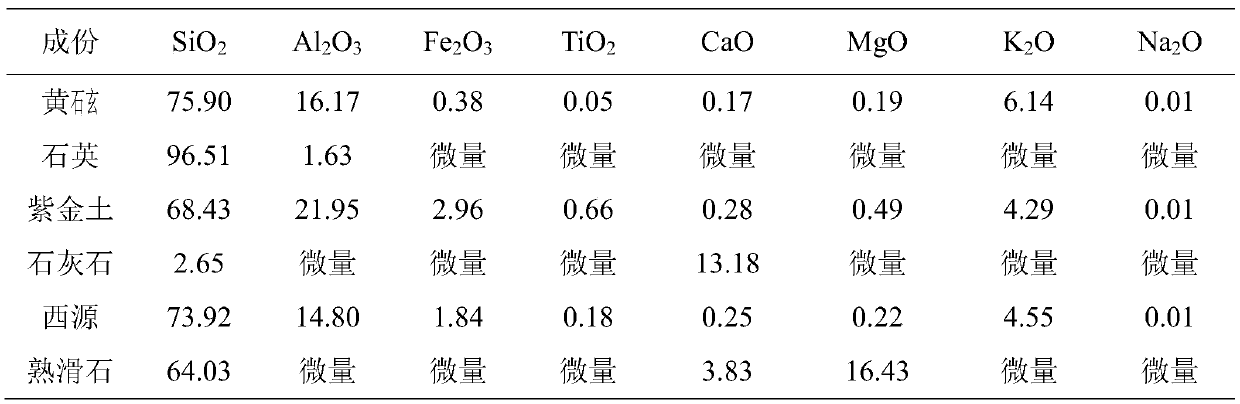

Method used

Image

Examples

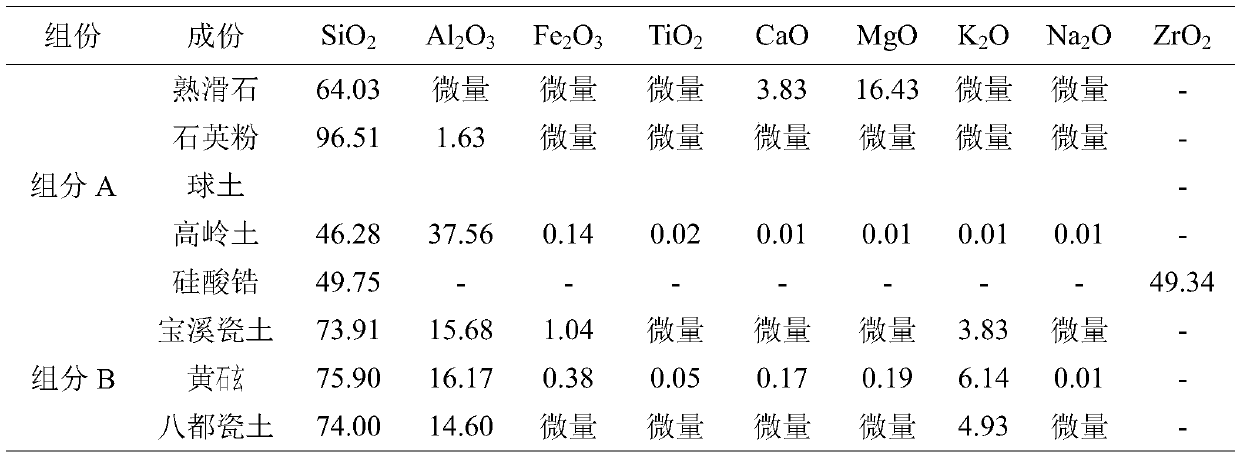

Embodiment 1

[0049] Embodiment 1: a high-strength blank for Longquan celadon products, the blank is made of component A and component B; according to the weight percentage that the total amount of component A is 100%, component A is: cooked 27% of talc, 47% of quartz powder, 10% of ball clay, 13% of kaolin and 3% of zirconium silicate; according to the weight percentage of 100% of the total amount of component B, component B is: Baoxi china clay 45% ,yellow 20%, Badu china clay 35%. In the formula of the billet, the magnesium-silicon ratio of the billet is more reasonable by adding cooked talc.

Embodiment 2

[0050]Embodiment 2: a high-strength blank for Longquan celadon products, the blank is made of component A and component B; according to the weight percentage that the total amount of component A is 100%, component A is: cooked 26% talc, 50% quartz powder, 10% ball clay, 11% kaolin, 3% zirconium silicate; according to the weight percentage of 100% of the total amount of component B, component B is: Baoxi porcelain clay 43% ,yellow 22%, Badu china clay 35%. In the formula of the billet, the magnesium-silicon ratio of the billet is more reasonable by adding cooked talc.

Embodiment 3

[0051] Embodiment 3: a high-strength blank for Longquan celadon products, the blank is made of component A and component B; according to the weight percentage that the total amount of component A is 100%, component A is: cooked 28% talc, 52% quartz powder, 9% ball clay, 10% kaolin, 1% zirconium silicate; according to the weight percentage of 100% of the total amount of component B, component B is: Baoxi china clay 45% ,yellow 20%, Badu china clay 35%. In the formula of the billet, the magnesium-silicon ratio of the billet is more reasonable by adding cooked talc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com