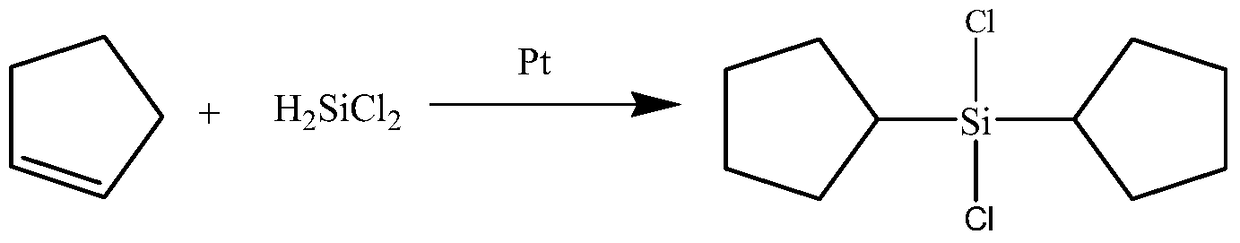

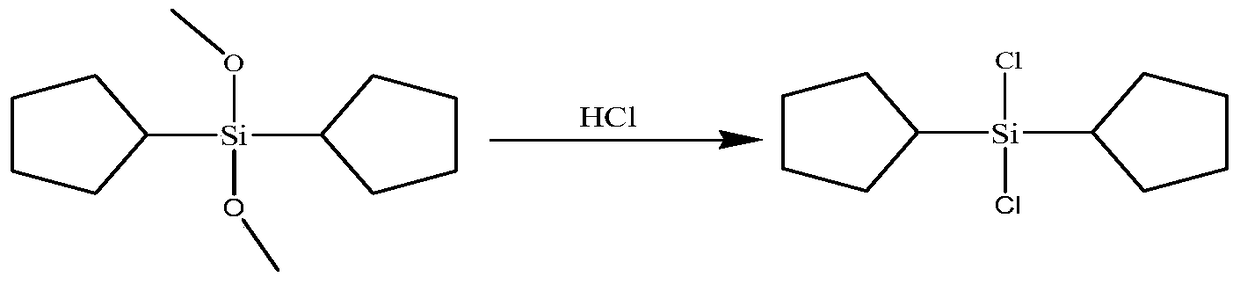

Synthesis process of dicyclopentyl dichlorosilane

A technology of dicyclopentyldichlorosilane and dicyclopentyldimethoxysilane, which is applied in the field of dicyclopentyldichlorosilane synthesis technology, can solve complex process, increase investment cost, production cost and operating cost , It is difficult to ensure job safety, environment, hygiene requirements and other issues, to achieve the effect of simple process, low equipment requirements and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 1L four-neck round-bottomed flask equipped with a stirrer, thermometer, gas bubbler and vent, first replace the air with nitrogen. Add 500g (2.2mol) dicyclopentyldimethoxysilane into the flask, start stirring, cool the reaction flask to 20-25°C with an ice-water bath, and slowly pass in dried HCl gas through a bubbler, (actually pass The molar ratio is 2.2 times that of dicyclopentyldimethoxysilane). The aeration time is 10h and the aeration time is 1h, the aeration speed is 0.48mol / h, after the reaction is completed, stop the agitation, let it stand for stratification, remove the upper layer of methanol, and collect the distillate at 105-110°C under reduced pressure at 4-5mmHg absolute pressure. Obtained 452.5 g of dicyclopentyldichlorosilane (ESI-MS: m / z=237[M+H] + ), a purity of 98.2%, and a yield of 85.4%.

Embodiment 2

[0026] In a 1L four-neck round-bottomed flask equipped with a stirrer, thermometer, gas bubbler and vent, first replace the air with nitrogen. Add 500g (2.2mol) dicyclopentyldimethoxysilane into the flask, start stirring, cool the reaction flask to 20-25°C with an ice-water bath, and slowly pass in dried HCl gas through a bubbler, (actually pass The molar ratio is 2.2 times that of dicyclopentyldimethoxysilane). The aeration time is 10h and the aeration time is 1h, the aeration speed is 0.48mol / h, after the reaction is completed, stop the agitation, let it stand for stratification, remove the upper layer of methanol, and collect the distillate at 105-110°C under reduced pressure at 4-5mmHg absolute pressure. Obtained 434.6 g of dicyclopentyldichlorosilane (ESI-MS: m / z=237[M+H] + ), a purity of 98.0%, and a yield of 81.9%.

[0027] Taking the dicyclopentyl dichlorosilane done in Example 2 as a raw material to synthesize dicyclopentyl diethylaminosilane:

[0028] In a 2L four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com