A kind of tetramethoxymethyl glycoluril derivative and preparation method thereof

A technology of tetramethoxymethyl glycoluril and ethoxymethyl glycoluril, which is applied in coating, organic chemistry, powder coating and other directions, can solve the problems of poor stability of polymer molecules, simple spatial structure, etc., and achieves easily controllable conditions, The availability of raw materials, the effect of expanding the spatial conformation and density of molecules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

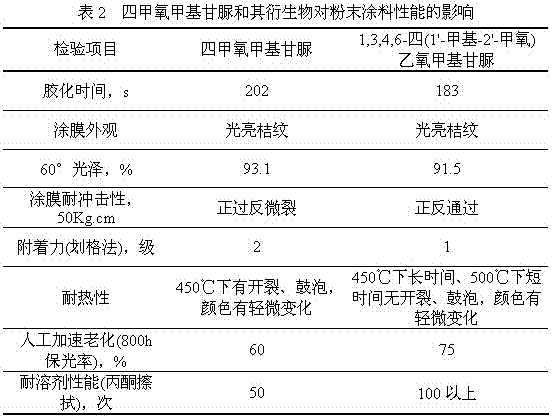

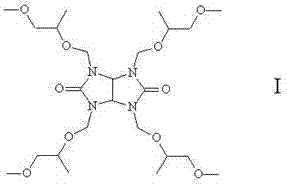

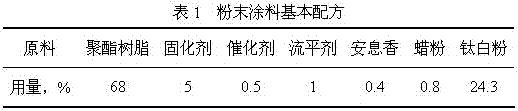

[0019] Add 3 g of tetramethoxymethyl glycoluril, 8 g of Amberlyst 35 resin, and 60 g of PGME into a 250 ml three-necked flask, heat up to 60° C., stir and react at -0.08 MPa for 9 hours, and distill off the generated methanol at the same time.

[0020] The reactant was suction-filtered with a Buchner funnel, and the filter residue was washed twice with PGME to recover the resin. The filtrate and washing liquid were combined, and the solvent PGME was recovered by distillation under reduced pressure to obtain 5.12 g of 1,3,4,6-tetrakis(1'-methyl-2'-methoxy)ethoxymethyl glycoluril, with a yield of 98.6% .

[0021] Measured product ESI-MS (m / z): 551.2 (M+1).

[0022] IR(KBr) v / cm -1 : 2929, 1712, 1454, 1392, 1110, 1031, 792.

[0023] 1 H-NMR (CDCl 3 ): δ1.02(d, J=6.3Hz, 12H), δ3.112~3.137(q, 4H), δ3.201(d, J=2.23Hz, 8H), δ3.252(s, 12H), δ3.713~3.748 (m, 8H), δ4.548 (s, 2H).

[0024] 13 C-NMR (CDC1 3 ): δ17.1, δ17.1, δ17.1, δ17.1, δ59.6, δ59.6, δ59.6, δ59.6, δ71.2, δ71.2, ...

Embodiment 2

[0026] The Amberlyst 15 resin was oven dried to 60% of its original weight.

[0027] Add 3 g of tetramethoxymethyl glycoluril, 6 g of dried Amberlyst 15 resin, and 70 g of PGME into a 250 ml three-necked flask, raise the temperature to 60° C., stir and react under the pressure of -0.07 MPa for 17 hours, and distill off the generated methanol at the same time.

[0028] The reactant was suction-filtered with a Buchner funnel, and the filter residue was washed twice with PGME to recover the resin. The filtrate and washing liquid were combined, and the solvent PGME was recovered by distillation under reduced pressure to obtain 5.19 g of 1,3,4,6-tetrakis(1'-methyl-2'-methoxy)ethoxymethyl glycoluril with a yield of 99.8% .

[0029] Measured product ESI-MS (m / z): 551.0 (M+1).

[0030] IR(KBr) v / cm -1 : 2943, 1712, 1485, 1384, 1024, 995, 790.

[0031] 1 H-NMR (CDCl 3 ): δ1.16(d, J=6.3Hz, 12H), δ3.198~3.26(q, 4H), δ3.372(d, J=2.41Hz, 8H), δ3.387(s, 12H), δ3.985~4.032 (m, 8H), δ4...

Embodiment 3

[0034] Soak the 732 resin in distilled water for 24 hours, then soak it in 2mol / L HCl solution for 24 hours, wash it repeatedly with distilled water until the pH value does not change, filter it and dry it in an oven.

[0035] Add 3g of tetramethoxymethyl glycoluril, 10g of dried 732 resin, 60g of PGME into a 250ml three-neck flask, heat up to 60°C, stir and react at -0.08MPa pressure for 15 hours, and distill off the generated methanol at the same time.

[0036] The reactant was suction-filtered with a Buchner funnel, and the filter residue was washed twice with PGME to recover the resin. The filtrate and washing liquid were combined, and the solvent PGME was recovered by distillation under reduced pressure to obtain 5.07 g of 1,3,4,6-tetrakis(1'-methyl-2'-methoxy)ethoxymethyl glycoluril, with a yield of 97.8% .

[0037] Measured product ESI-MS (m / z): 551.6 (M+1).

[0038] IR(KBr) v / cm -1 : 2929, 1714, 1479, 1238, 1091, 1031, 790.

[0039] 1 H-NMR (CDCl 3): δ1.14(d, J=6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com