Intelligent visual ethylene cracking furnace teaching model

An ethylene cracking furnace and teaching model technology, applied in the field of petrochemical olefin cracking equipment, can solve the problems of complicated experiments, energy and equipment consumption, inconvenient for research and analysis, etc., and achieve the effect of clear research and learning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

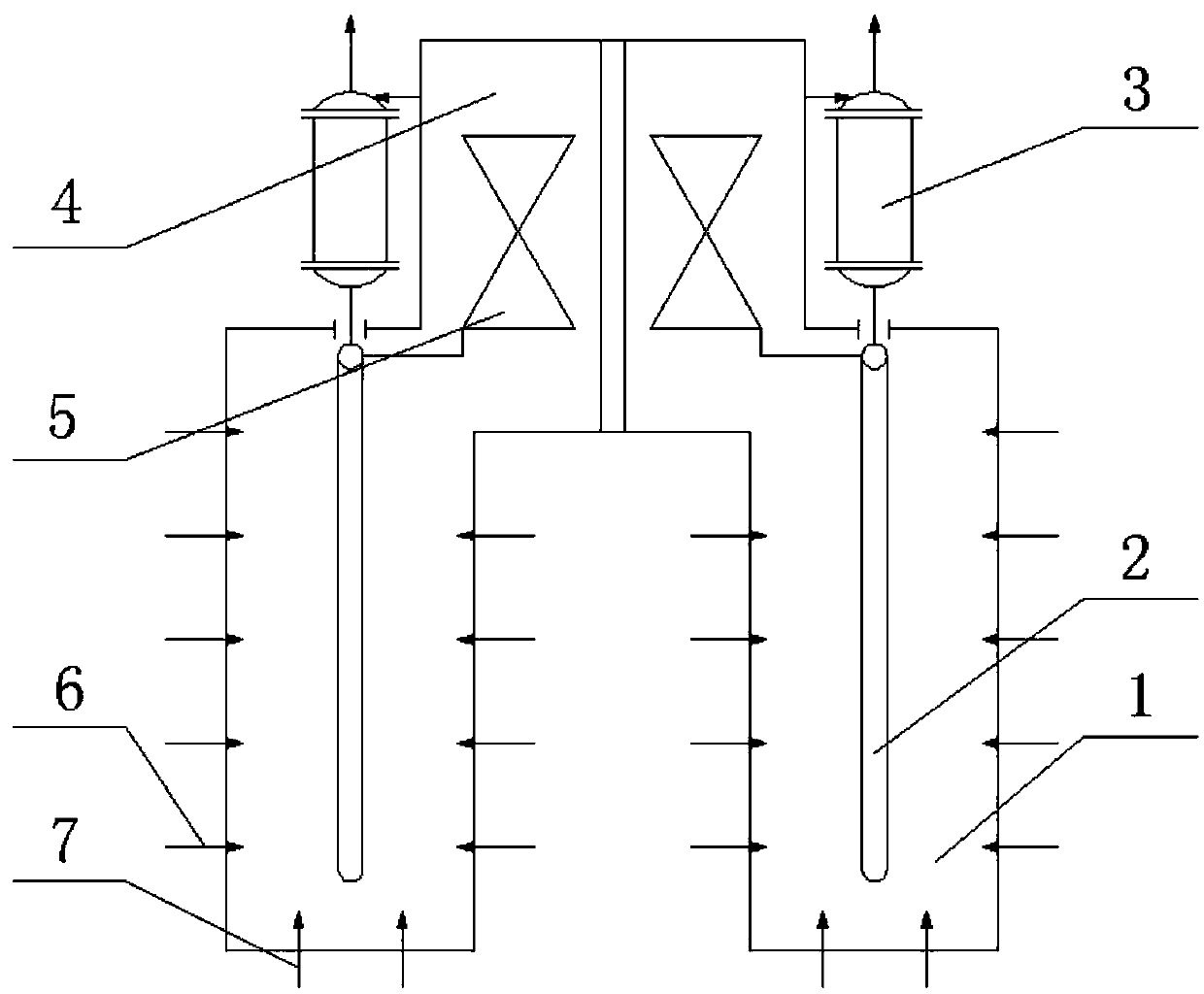

[0022] An intelligent visual ethylene cracking furnace teaching model, including symmetrically distributed radiant section 1, convection section 4 and quench boiler 3, vertically distributed radiant tubes 2 are arranged inside the radiant section, bottom burners 7 and Side wall burner 6; the convection section is located on the upper part of the radiation section, and the convection tube 5 placed horizontally is arranged inside; the convection section is formed with a liquid inlet connected to the convection tube, and the discharge port of the convection tube is connected to the liquid inlet of the radiant tube The discharge port of the vertically distributed radiant tube is connected to the liquid inlet of the quenching boiler. The quenching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com