Preparation method of waxberry-flavored wine

A technology of flavor and bayberry, applied in the field of food and beverage processing, can solve problems such as waste, achieve the effect of avoiding waste, avoiding waste and economic loss, and overcoming technical prejudice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

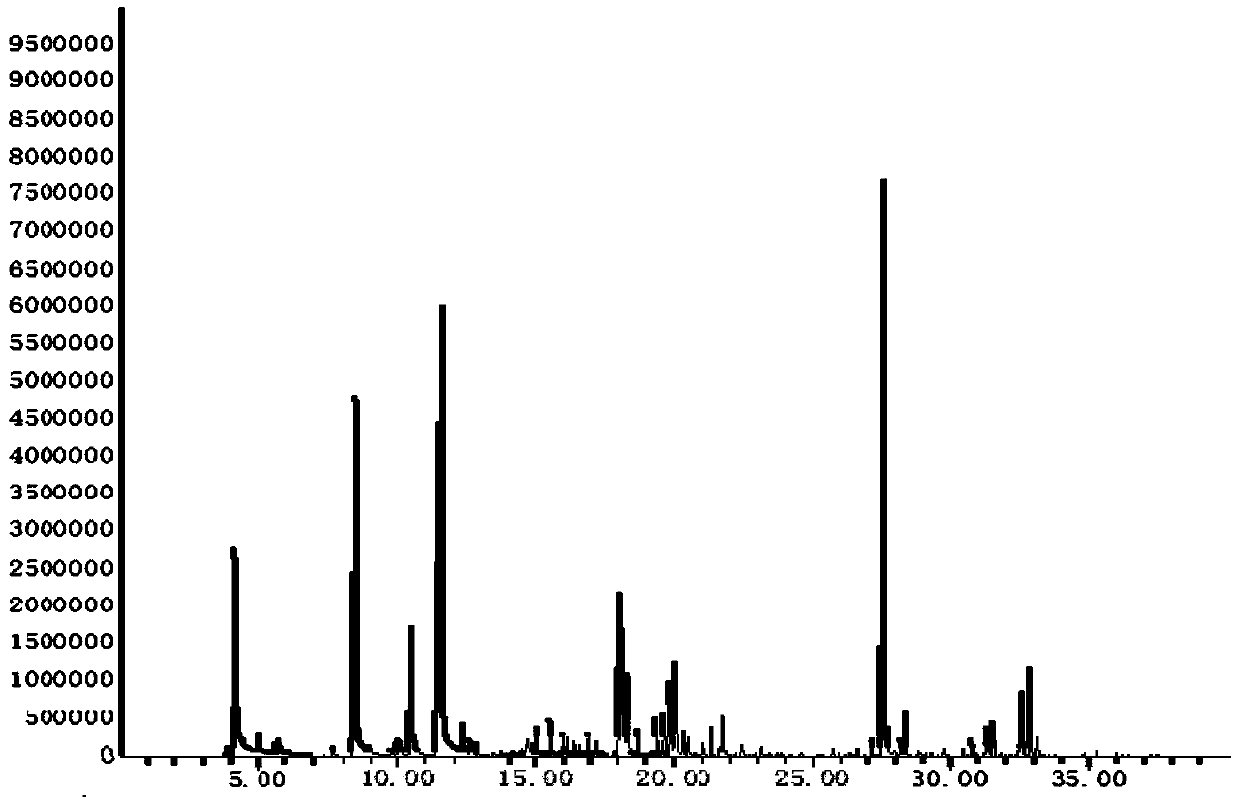

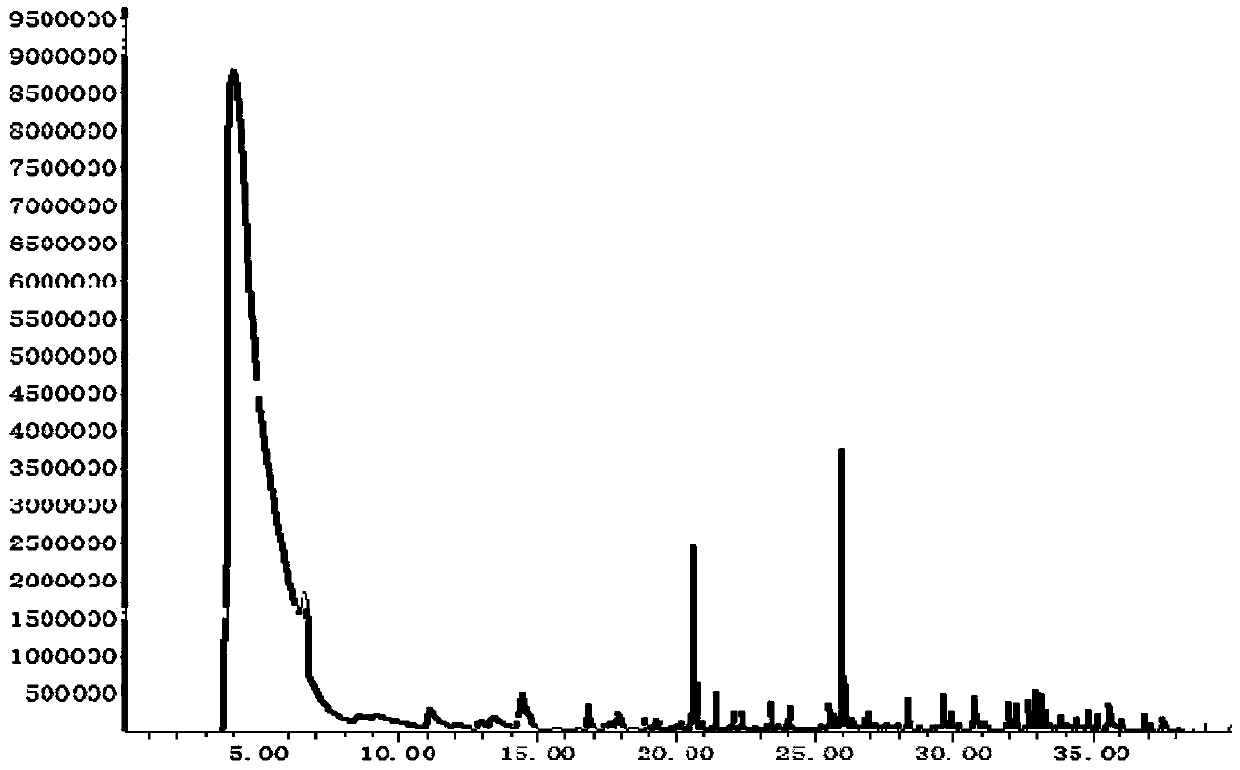

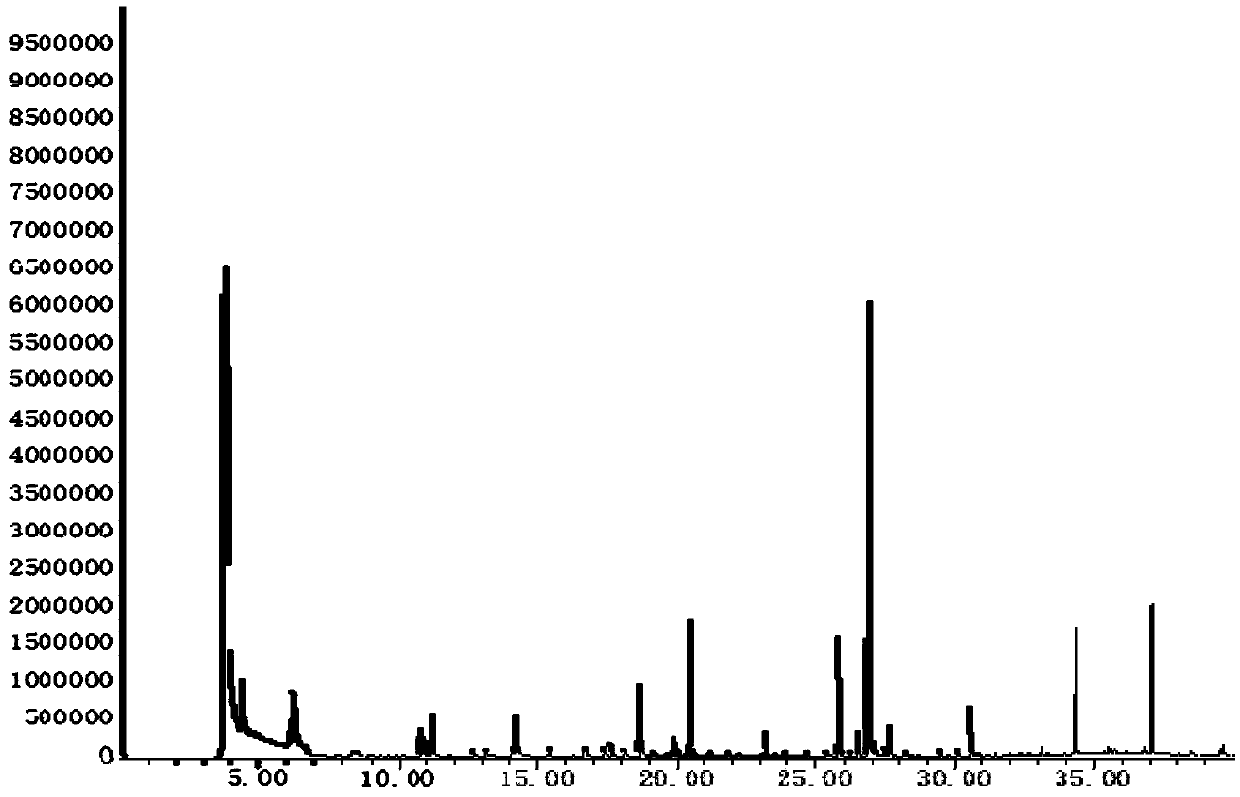

Image

Examples

Embodiment 1

[0023] A kind of preparation of red bayberry flavor wine comprises the following steps:

[0024] At first the preparation of red bayberry soaked wine: select fresh ripe red bayberry with soluble solid content ≥ 9% as raw material, remove leaves, fruit stems, etc., according to the following ratio: stoste: fresh red bayberry: rock sugar=20L:20kg:1kg, prepare red bayberry Soak the wine and obtain distiller's residue at the same time; wherein the stock solution of the soaked wine is shochu with an alcohol content of 42 degrees or more after rice fermentation.

[0025] Secondly, soak the wine dregs in a still to obtain distilled wine: Put 10kg of wine dregs into the still and heat at a temperature of 80-90 degrees Celsius. After 3 hours, 2.5L of distilled wine liquid can be obtained, and the alcohol content is measured by an alcohol meter. is 63 degrees.

[0026] Finally, the preparation of bayberry-flavored wines with different alcohol levels: the wine liquid soaked in bayberry ...

Embodiment 2

[0028] A kind of preparation of red bayberry flavor wine comprises the following steps:

[0029] At first the preparation of red bayberry soaked wine: select fresh ripe red bayberry with soluble solid content ≥ 9% as raw material, remove leaves, fruit stems, etc., according to the following ratio, stoste: fresh red bayberry: rock sugar=5L:5kg:1kg, prepare red bayberry Steep the wine while obtaining the lees. Wherein the steeping wine stock solution is shochu whose alcohol content is more than 42 degrees after rice fermentation.

[0030] Secondly, after soaking red bayberry wine residue and distilling it in a still, distilled wine is obtained: put 10kg of wine residue into the still, heat it at a temperature of 90-100 degrees Celsius, and after 3 hours, 3.0L of distilled wine liquid can be obtained, and the alcohol content is measured by an alcohol meter is 58 degrees. However, due to the high temperature, too much water in the soaked distiller's dregs evaporates, and there i...

Embodiment 3

[0033] At first the preparation of red bayberry soaked wine: select fresh ripe red bayberry with soluble solid content ≥ 9% as raw material, remove leaves, fruit stems, etc., do not add rock sugar, according to the original solution: fresh red bayberry=1.0L:1.0kg, prepare red bayberry to soak wine while obtaining lees. Wherein the steeping wine stock solution is shochu whose alcohol content is more than 42 degrees after rice fermentation.

[0034] Secondly, distilled wine is obtained after the red bayberry soaked wine residue is distilled by a still: put 10kg of bayberry soaked wine residue soaked in about 2 months into the still, heat it at a temperature of 85 degrees Celsius, and obtain distilled wine liquid 2.6 after 3 hours. L, the alcohol content measured by the alcohol meter is 62 degrees.

[0035] Finally, the preparation of bayberry-flavored wines with different alcohol levels: the wine liquid soaked in bayberry after soaking for 2 months is selected, the alcohol cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com