Digital printing method

A technology of digital printing and inkjet printing, applied in dyeing, textile and papermaking, etc., can solve the problems of general anti-seepage effect and large dosage.

Active Publication Date: 2016-04-20

BEIJING SMART GARMENTS

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, at present, the industry generally adopts the method of fabric pretreatment to prevent the ink on the subsequent printing from seepage, such as adding an anti-seepage agent to the pretreatment liquid, but the effect of anti-seepage is general, and the amount of such additives Not small

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

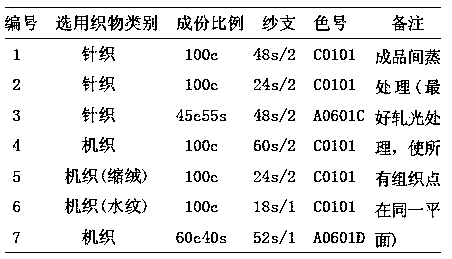

[0025] The physical adsorbent is calcium carbonate powder liquid, and the infiltration rate (%) obtained by comparison is as follows:

[0026]

Embodiment 2

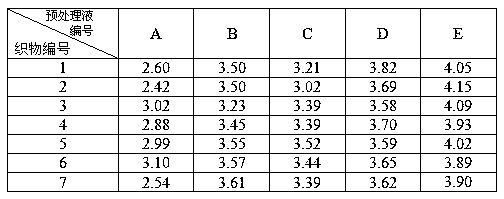

[0028] The physical adsorbent is mesoporous silica, and the permeability rate (%) obtained by comparison is as follows:

[0029]

Embodiment 3

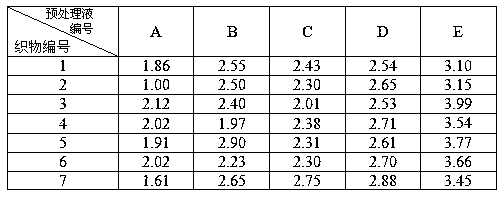

[0031] The physical adsorbent is mesoporous titanium dioxide, and the permeability rate (%) obtained by comparison is as follows:

[0032]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a digital printing method. The digital printing method comprises the steps of fabric pretreatment, drying, physical adsorption agent spraying, drying before printing, inkjet printing, drying after printing, steaming, washing and drying. Based on the principle that a porous surface is formed on fabric by adopting calcium carbonate or mesoporous silica or mesoporous titania as a physical adsorption agent, and bleeding phenomena can be reduced, the physical adsorption agent is sprayed in advance according to printing patterns, a closed layer is formed in an interface between an area needing to be printed and an unprinted area of the fabric to stop dye ink from bleeding towards the unprinted area.

Description

technical field [0001] The invention relates to the field of jet printing, in particular to a digital printing method. Background technique [0002] With the overall improvement of today's world economic level, people's demand for clothing, textiles, etc. is becoming more and more individualized and diversified, which has brought a certain positive impact on the traditional textile industry, requiring that the manufacturing field must also be transformed into Multi-variety and small batch production process. The emergence of digital printing technology just meets and adapts to this new market demand. Digital printing technology is the product of the integration of advanced technologies such as precision machinery, computer and optoelectronic integration, and is a major breakthrough in traditional printing technology. As customers' demand for digital printing products of different fabric types, especially digital printing products of high-grade fabrics, is increasing signifi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06P5/30D06P1/673D06P1/651D06P1/649D06P1/653D06P1/48D06P3/14

CPCD06P1/445D06P1/48D06P1/6491D06P1/65118D06P1/6533D06P1/673D06P1/6735D06P1/67383D06P3/14D06P5/002D06P5/30

Inventor 赵军伟林红

Owner BEIJING SMART GARMENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com