Raised floor

A raised floor and panel technology, applied in the field of building materials, can solve the problems of difficulty in maintenance and inspection construction work, increase costs, time-consuming and labor-intensive, etc., and achieve the effects of simple structure, time saving, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

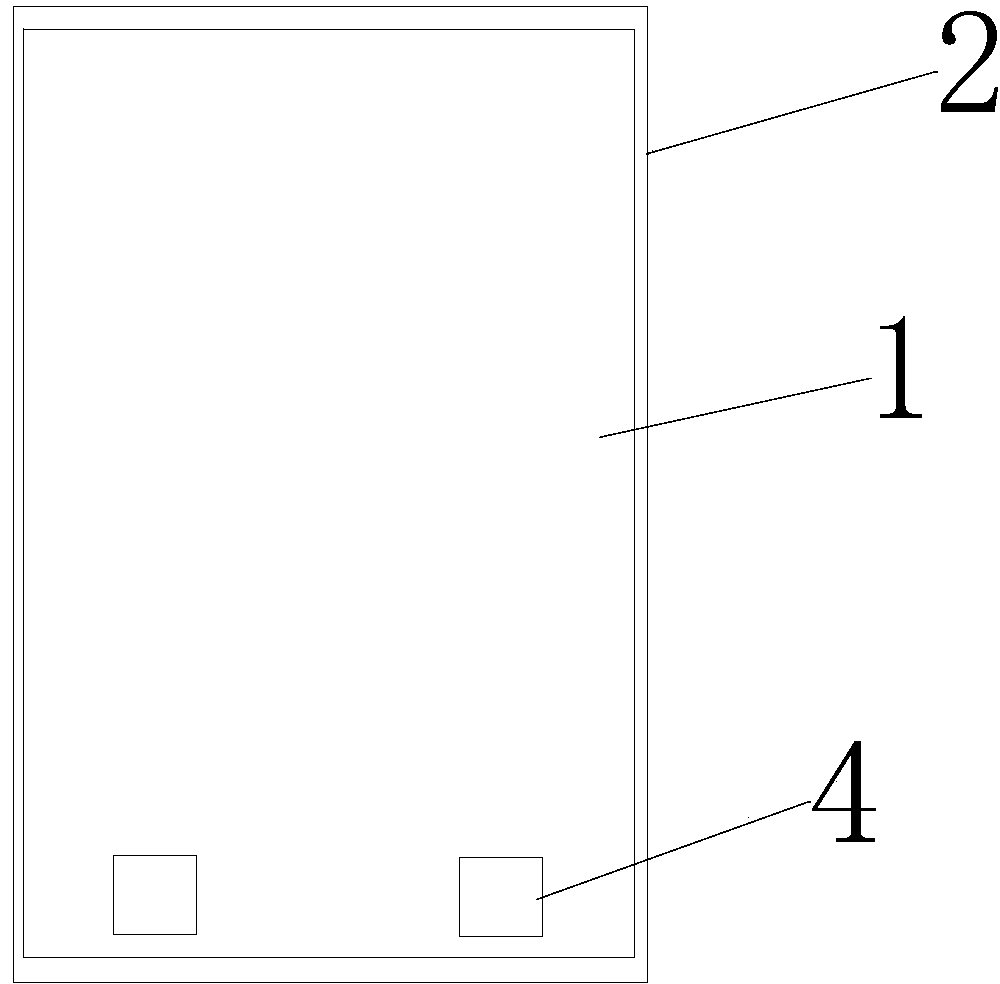

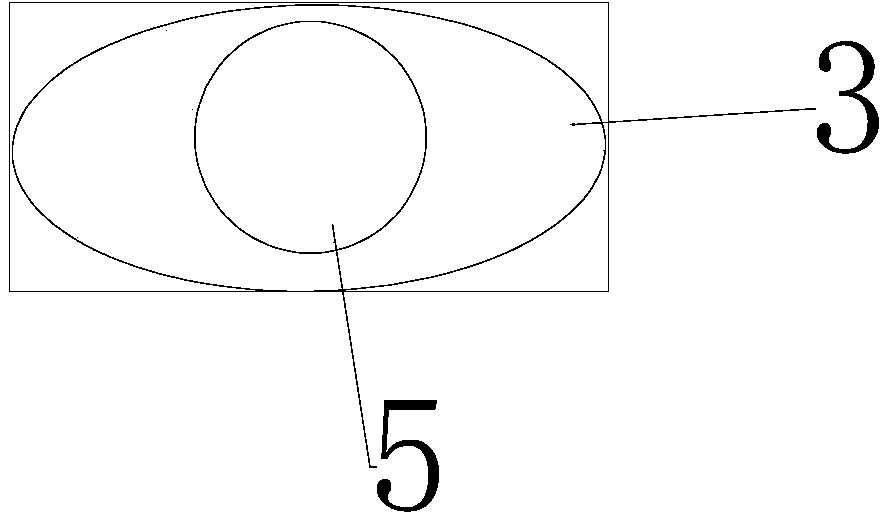

[0013] Such as figure 1 and figure 2 As shown, including the base body, the base body is provided with an upper panel 1, and a bottom plate 2 is provided below, and the position directly in front of the upper end surface of the upper panel 1 is provided with two symmetrically distributed concave grooves 3, through which the concave grooves 3. Open the access floor, a cover plate 4 is arranged above the concave groove 3, and the cover plate 4 is opened and closed by spring control. The cover plate ensures that dust does not fall into the floor, and the concave groove 3 is provided with There are opening holes 5, and the floor body is opened through two opening holes 5, and the distance between the two concave grooves 3 is 80mm-260mm. The diameter of the opening hole 5 is about 80mm, which is in line with the comfort of human fingers, and saves manpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com