A method for strengthening the walls of raw earth buildings

A technology for building walls and raw earth walls, applied in construction, building maintenance, building components, etc., can solve the problems of high cost, high cost, complicated construction technology, etc., and achieve the effect of small disturbance, simple and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

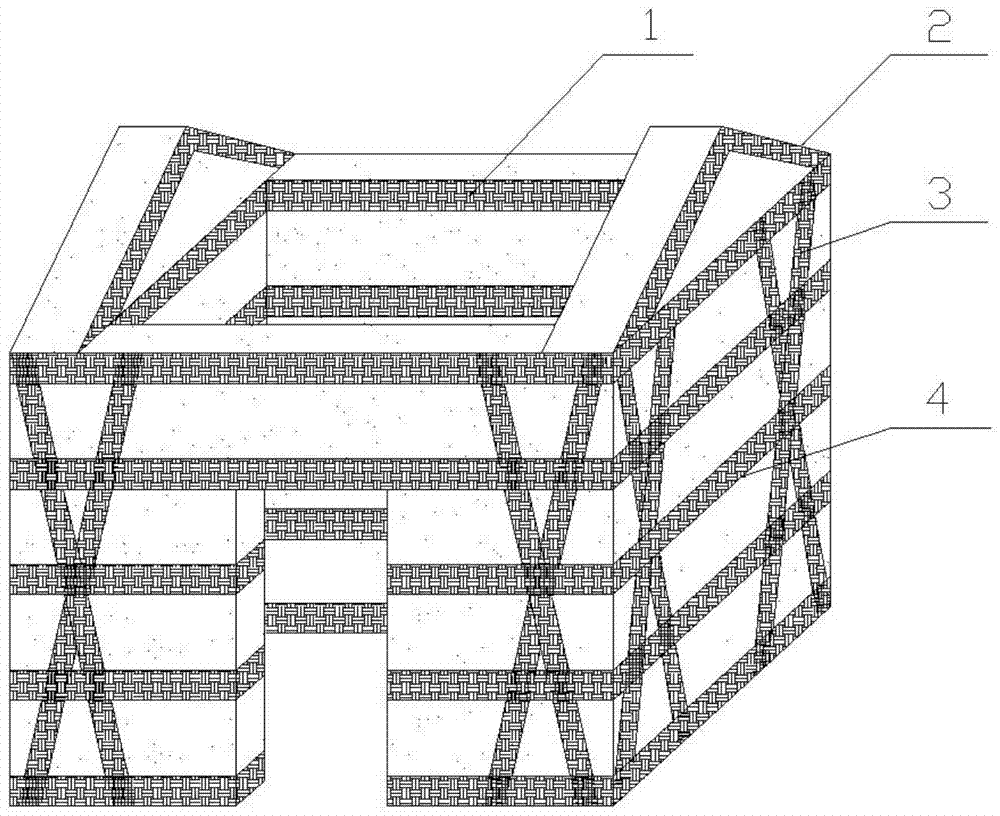

[0038] A single-story single-bay rammed earth house 1# built in a laboratory is 2.6m long, 2.4m wide and 2.2m high. The gable wall is 0.6m high and 0.6m thick. It is mainly reinforced by double-layer horizontal bonding. Reinforcement diagram as figure 1 , shown in 2. The method is constructed in the following steps:

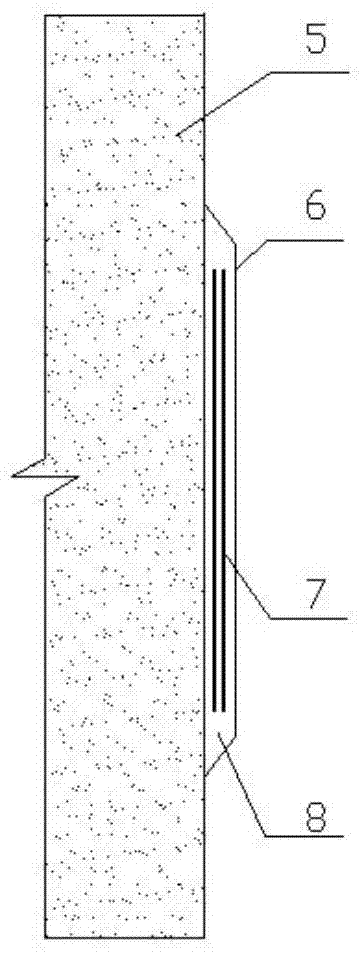

[0039] 1. Properly polish the inner and outer surfaces of the uneven raw soil wall 5 to make it basically flat;

[0040] 2. Select the pasting method, and cut the tarpaulin for pasting into a width of 20cm. Stretch the thread on the inner and outer walls, the width of the thread is 20cm, this area is the sticking position, and the sticking position of the inner and outer walls is kept at the same horizontal position, such as figure 1 As shown in 1 and 4, the gable wall can be pasted at an oblique direction along the direction of the wall, such as figure 1 As shown in 2, the pasting position at the junction of the vertical and horizontal walls can be oblique,...

Embodiment 2

[0048] A single-storey single-bay rammed earth house built in a laboratory is 2.6m long, 2.4m wide and 2.2m high. The gable wall is 0.6m high and 0.6m thick. It is mainly reinforced by double-layer horizontal bonding. Reinforcement diagram as figure 1 , shown in 2. The method is constructed in the following steps:

[0049] 1. Properly polish the inner and outer surfaces of the uneven raw soil wall to make it basically flat;

[0050]2. Select the pasting method, and cut the carbon fiber cloth used for pasting into a width of 18cm. Stretch lines on the inner and outer walls, the width of the stretch lines is 20cm, and this area is the sticking position. The pasting position of the inner and outer walls is kept at the same horizontal position, the gable wall can be pasted in an oblique direction along the direction of the wall, and the pasting position at the junction of the vertical and horizontal walls can be inclined.

[0051] 3. Brush liquid water glass with a modulus of...

Embodiment 3

[0058] A single-storey single-bay rammed earth house built in a laboratory is 2.6m long, 2.4m wide and 2.2m high. The gable wall is 0.6m high and 0.6m thick. It is mainly reinforced by double-layer horizontal bonding. Reinforcement diagram as figure 1 , shown in 2. The method is constructed in the following steps:

[0059] 1. Properly polish the inner and outer surfaces of the uneven raw soil wall to make it basically flat;

[0060] 2. Select the pasting method, and cut the thick canvas for pasting into a width of 15cm. Stretch lines on the inner and outer walls, the width of the stretch lines is 20cm, and this area is the sticking position. The pasting position of the inner and outer walls is kept at the same horizontal position, the gable wall can be pasted in an oblique direction along the direction of the wall, and the pasting position at the junction of the vertical and horizontal walls can be inclined.

[0061] 3. Brush liquid water glass with a modulus of 3.3 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com