Bionic structure and design method of wind-resistant and load-reducing box girder of gantry crane

A gantry crane and box girder technology, applied in support structure, bottom support structure, design optimization/simulation, etc., can solve the problem of lack of systematic research to reveal the characteristics of wind-induced effects of cranes, unsystematic special case research, and blank design of wind resistance and load reduction and other problems, to achieve the effect of easy operation of design steps, simple design steps, and reduction of wind-induced load fluctuation amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

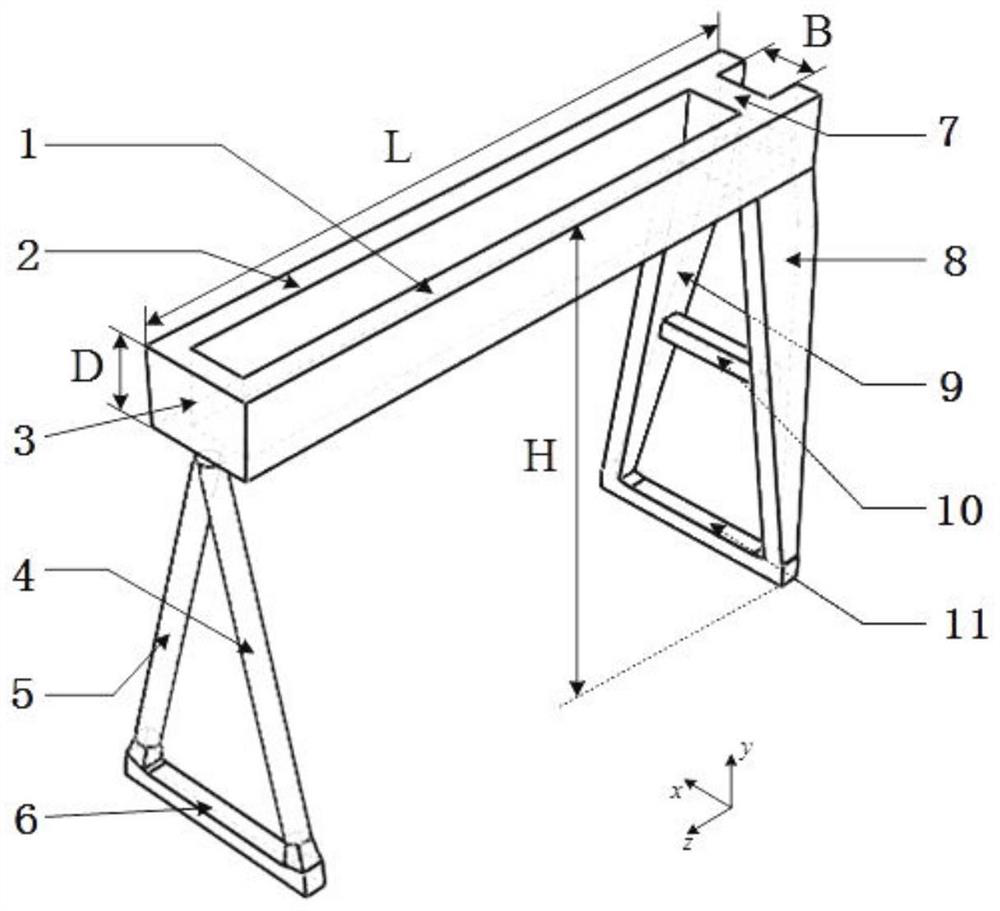

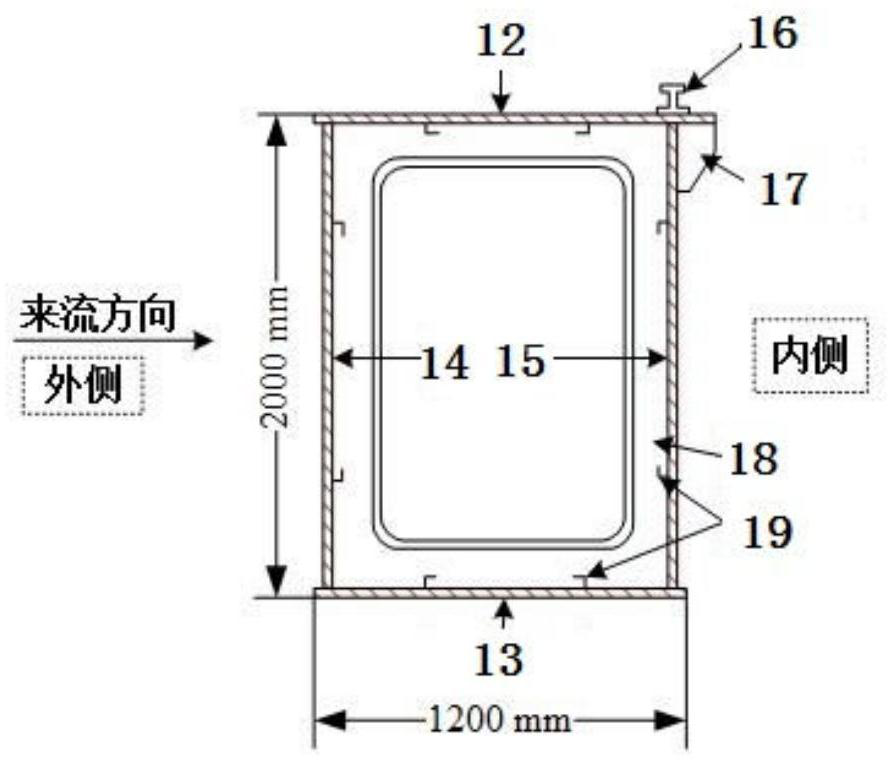

[0090] In the art, the main girder of a gantry crane generally adopts a box girder structure with a rectangular or trapezoidal cross-section. Figure 2 gives a

[0092] The box puffer is commonly known as a box fish, and it has been pointed out earlier that its box-shaped structure does not affect its swimming speed. In this embodiment,

Embodiment 2

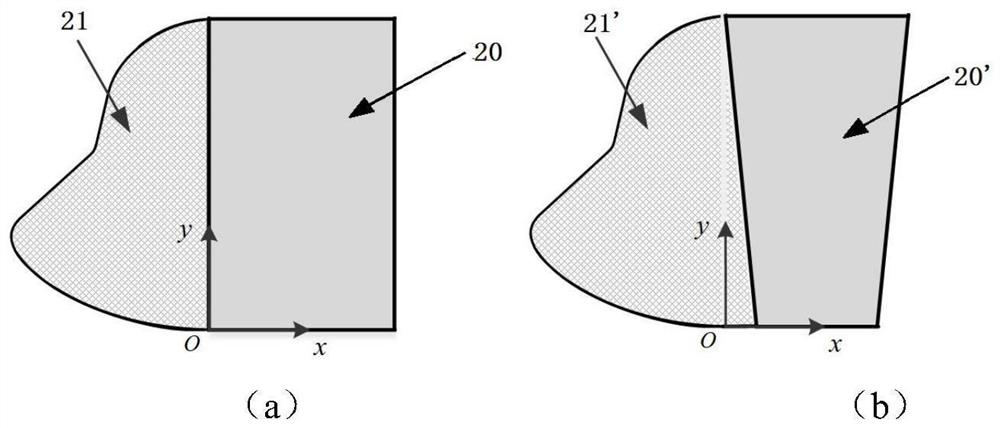

[0104] Taking the cuboid part as the fish body, the extracted outline of the box puffer is divided into three parts: fish mouth, fish body and fish tail. like

[0105] Extract the mouth part of the puffer fish in the box, and enlarge it to the height of the mouth of the fish and the height of the box girder. Then according to the three paragraphs

[0110]

[0112] The value range of the starting and ending points of the line segment:

[0113]

[0116]

[0117]

[0120]

[0121]

[0124]

[0125]

[0128]

[0129]

[0132]

[0133]

[0137]

[0140]

[0143] In actual use, according to the three-dimensional biomimetic outline, the attachment member of the corresponding structure can be manufactured by utilizing lightweight materials,

Embodiment 3

[0160]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com