Segmented and combined type wind turbine generator blade and manufacturing method thereof

A wind turbine and segmented combination technology is applied to wind turbines, wind turbines that are in the same direction as the wind, and wind power generation. It is difficult to guarantee and other problems, so as to reduce the difficulty of transportation, avoid insufficient glue injection, and save transportation costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with specific examples.

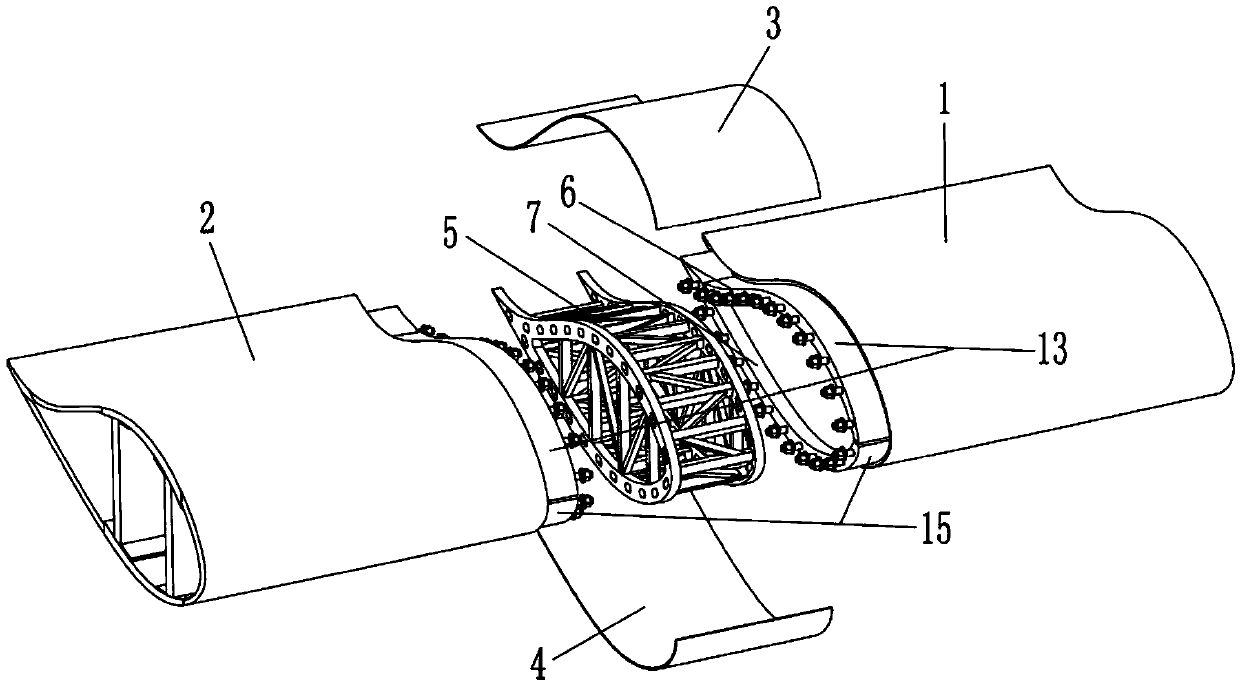

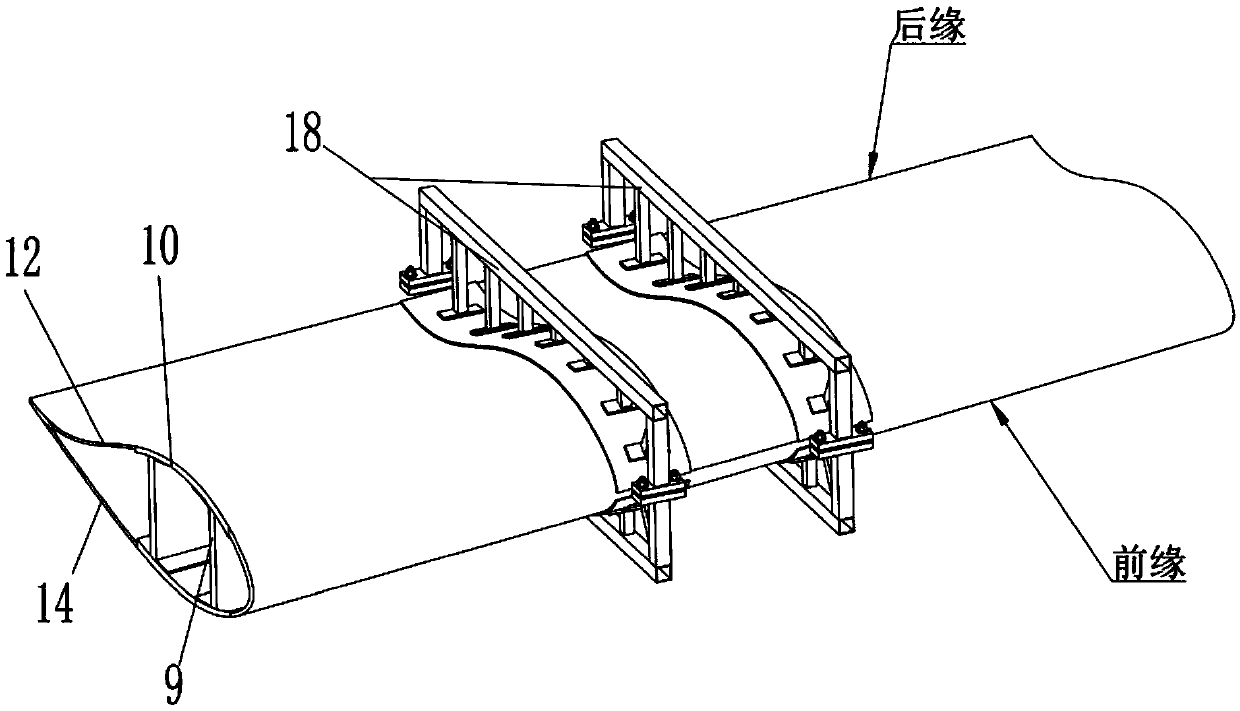

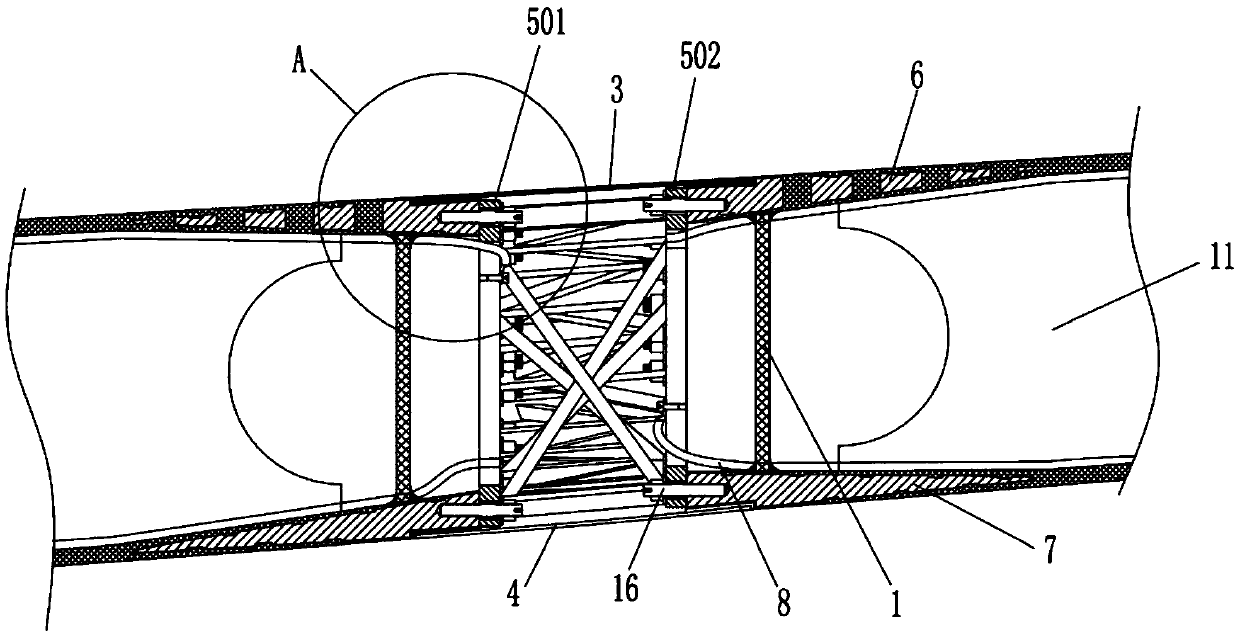

[0036] like Figure 1 to Figure 8As shown, the segmented combined wind turbine blade described in this embodiment includes a blade tip section 1, a blade root section 2, a first aerodynamic shape combination plate 3, a second aerodynamic shape combination plate 4, and a truss-type steel structure 5. The first insert 6, the second insert 7, the lightning protection wire 8, the blade tip section 1 and the blade root section 2 are built with a web 9 and a main beam 10, and an end face is made at a distance of 100 mm from the end face The baffle plate 11, the inside of the windward surface 12 of the blade tip section 1 and the blade root section 2 are attached and fixed with a first insert 6, the shape and size of the first insert 6 is matched with the inside of the windward surface 12, and exposed There is an adhesive surface 13 with a width of 100mm, which is used for pasting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com