Thermoelectric power generation method and thermoelectric power generation equipment

A thermoelectric power generation and equipment technology, applied in mechanical equipment, ocean energy power generation, machines/engines, etc., can solve the problems of low power generation efficiency and high power generation cost, and achieve high power generation efficiency, low power generation cost and good adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

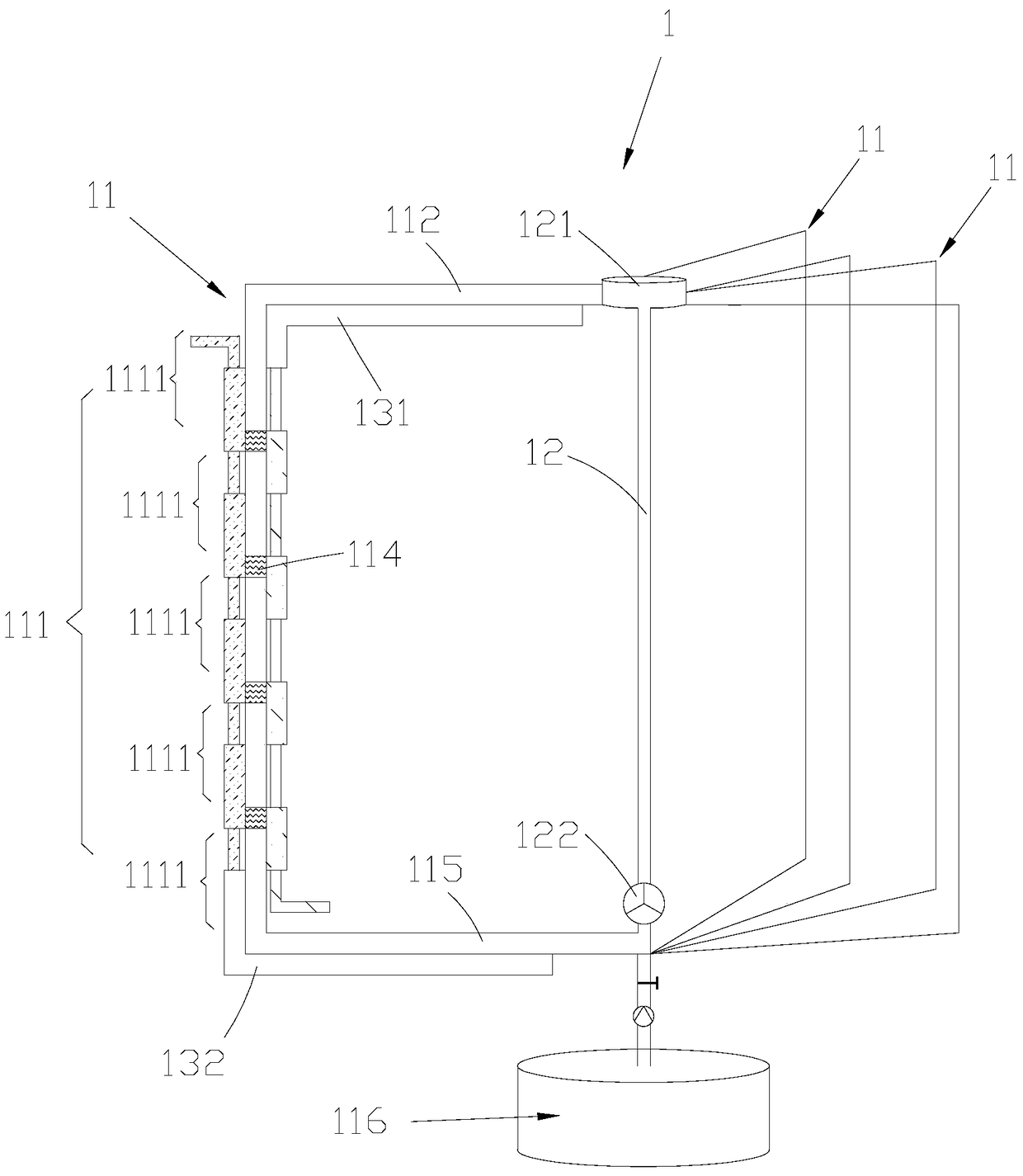

Embodiment 1

[0024] This embodiment provides a thermoelectric power generation method, using cold seawater at a depth of 300-1000 meters as a lower-temperature medium, hot seawater at a depth of 100-200 meters on the ocean surface as a higher-temperature medium, and carbon dioxide as a main working medium for power generation, including the following steps:

[0025] 1) With the help of a higher temperature medium, that is, the extracted higher temperature seawater, the working fluid is heated through heat exchange to make it gasify and rise;

[0026] 2) With the help of a lower temperature medium, that is, the extracted lower temperature seawater, the gasified and rising working medium is cooled through heat exchange to condense it into a liquid state;

[0027] 3) Diversion liquid working medium flows down from a high place, driving the impeller to rotate to generate power;

[0028] 4) divert the concentrated working medium that has done work, and repeat step 1).

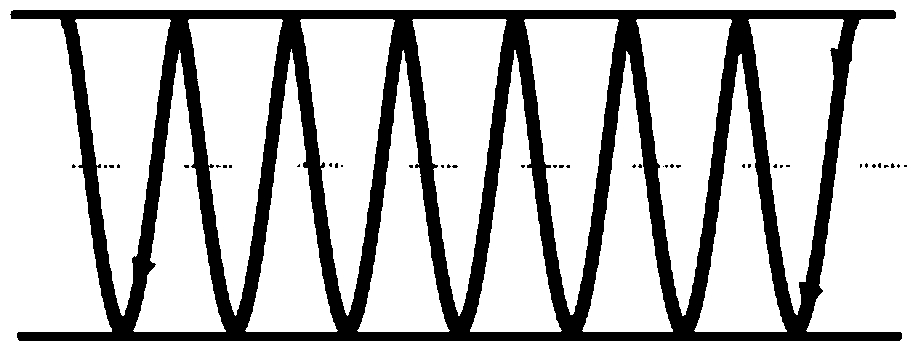

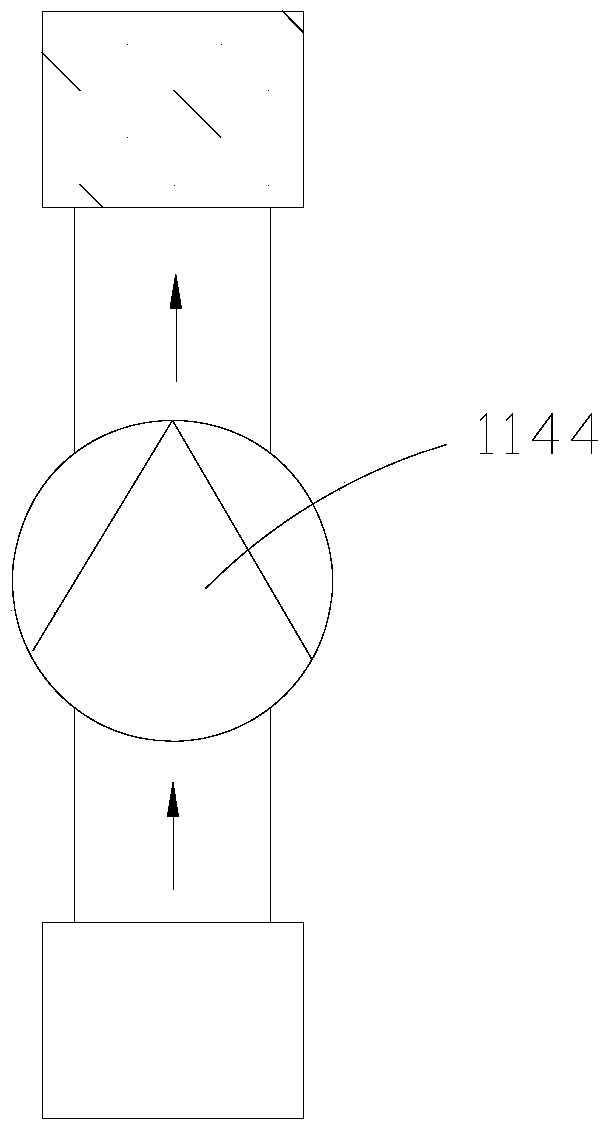

[0029] In this embodime...

Embodiment 2

[0053] The temperature difference power generation equipment 1a of this embodiment is mainly used in relatively cold regions. Since the air temperature in cold regions is relatively low, especially in deep winter, the temperature difference between the air at high altitude and the seawater under the sea surface is large, and the temperature difference can be used to generate power. In a specific implementation, the lower end of the thermoelectric power generation equipment 1a is set under the sea surface, and the seawater collected from there is 4-5 degrees Celsius as a relatively high-temperature medium, and the upper end extends to the high altitude, and the air below 0 degrees Celsius in the high altitude is used as the medium. lower temperature media.

[0054] Such as Figure 5 As shown, the principle of the thermoelectric power generation device 1a in this embodiment is the same as that of the thermoelectric power generation method in the first embodiment, and the overall...

Embodiment 3

[0063] The thermoelectric power generation equipment 1b in this embodiment is applied in the deep sea (the depth exceeds 500 meters), and the low-temperature seawater in the deep sea is used as the lower-temperature medium, and the seawater extracted from the shallow sea is used as the higher-temperature medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com