Multi-cylinder rotary type compressor

A technology of rotary compressors and cylinders, used in rotary piston/oscillating piston pump components, elastic fluid rotary piston/oscillating piston pump combinations, and mechanical equipment, etc. Influence and affect the accuracy of the compression mechanism and the reduction of compression efficiency, etc., to avoid deformation, ensure the centering accuracy, and ensure the performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

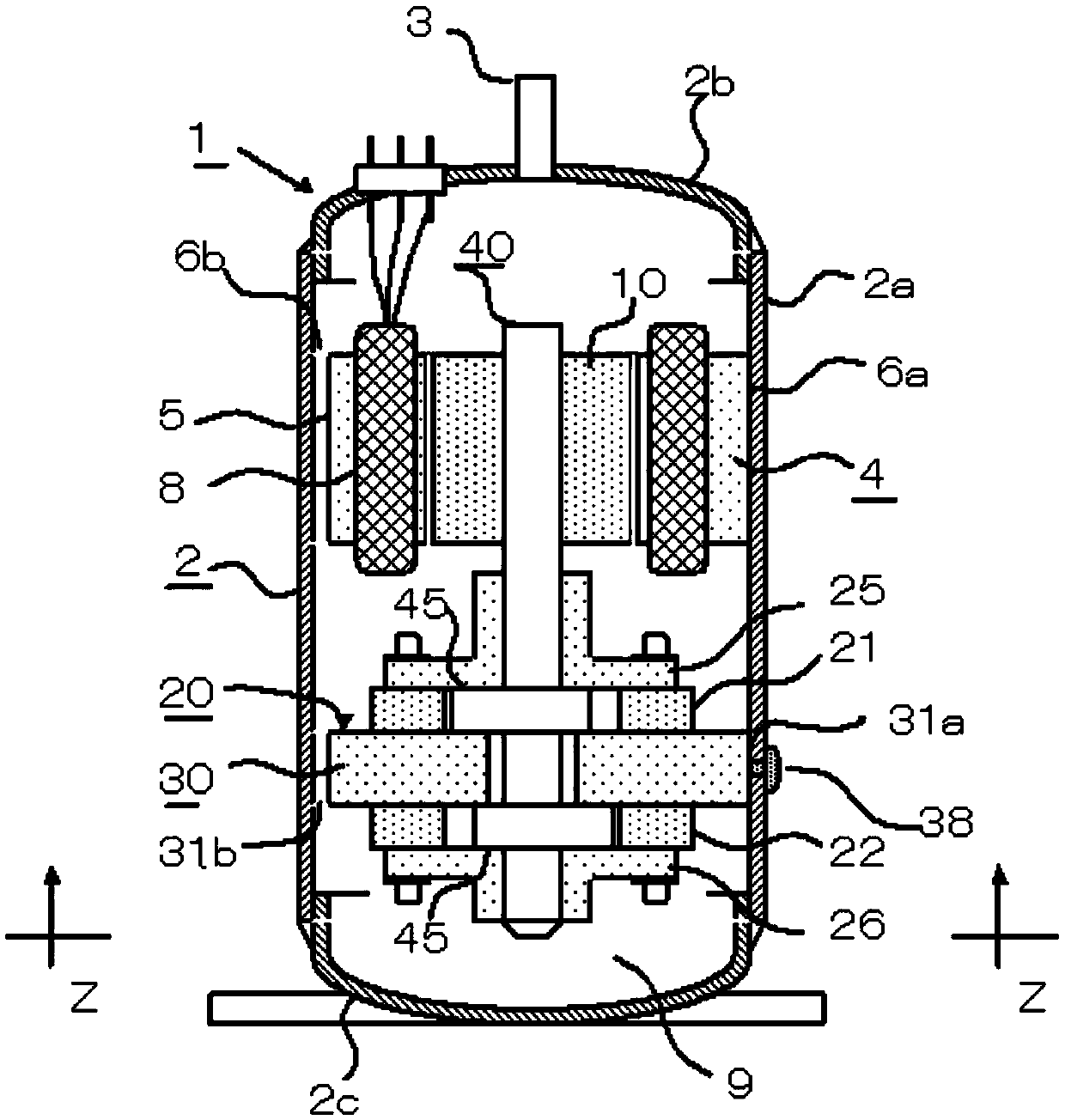

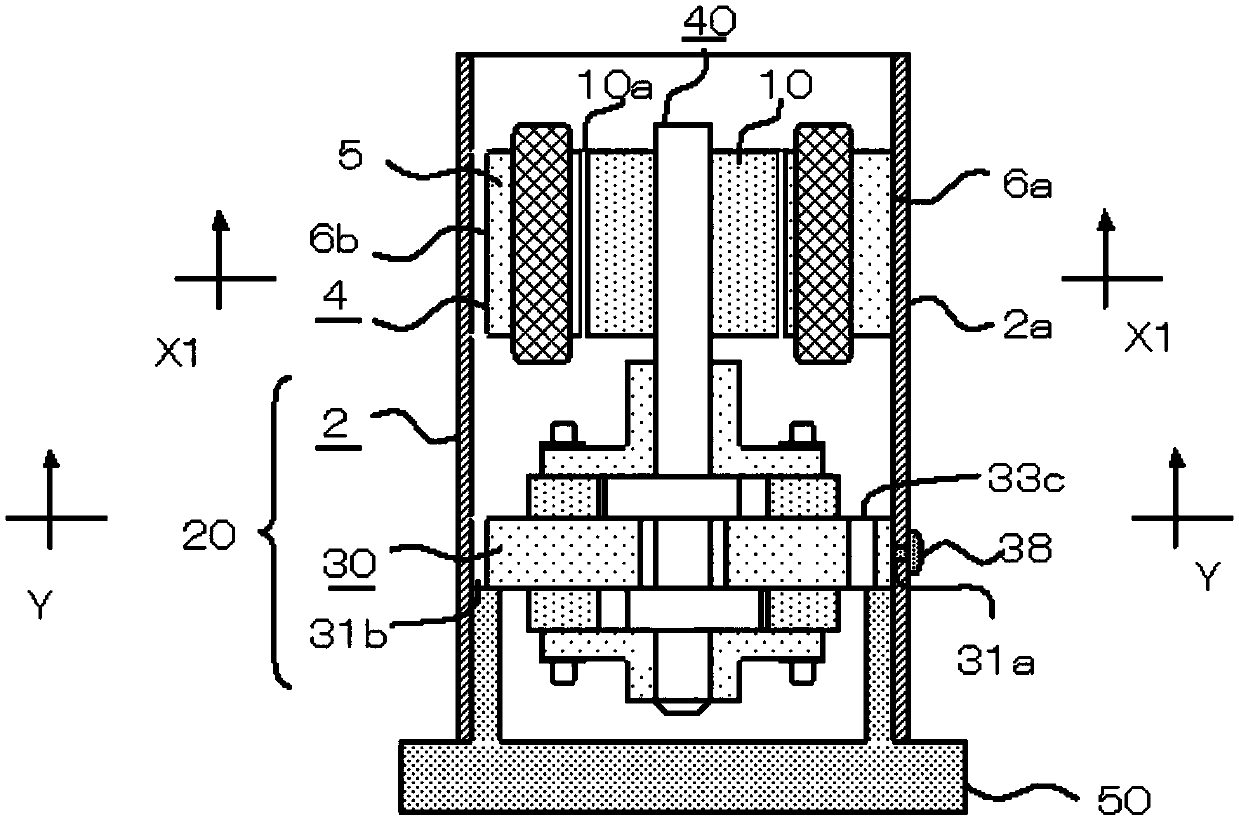

[0044] figure 1 The internal structure of the completed multi-cylinder rotary compressor 1 is shown. The sealed casing 2 is composed of a cylindrical casing 2a, a first end plate 2b and a second end plate 2c welded to the openings at both ends thereof, and the motor 4 and the compression mechanism part 20 are accommodated therein. In addition, the bottom of the sealed housing 2 has an oil storage chamber 9 .

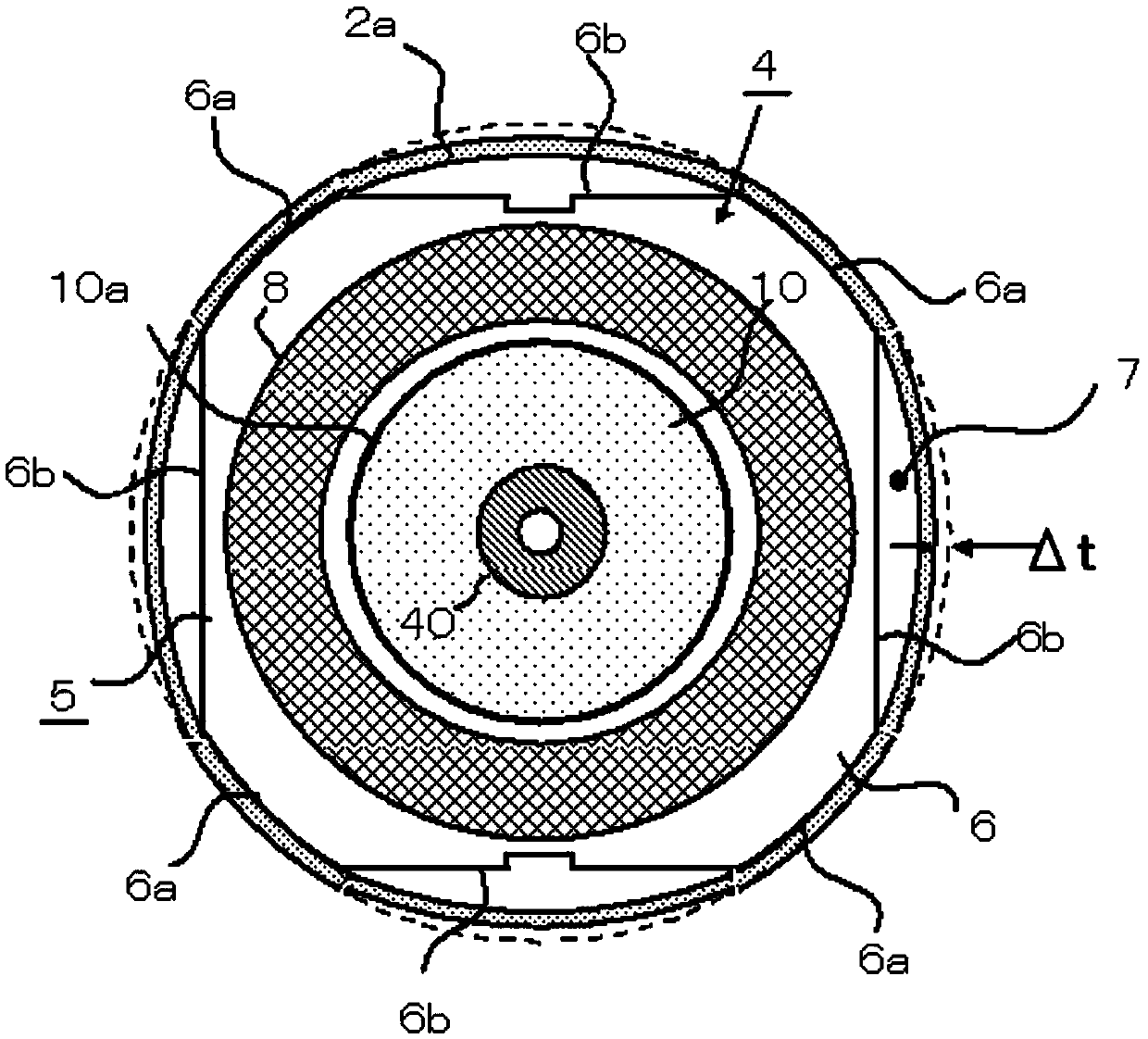

[0045] The motor 4 is composed of a stator 5 and a rotor 10, and the compression mechanism part 20 is composed of a cylinder 21 and a cylinder 22 provided with a compression chamber, a partition plate 30 provided between these cylinders, a crankshaft 40 that eccentrically drives a piston 45 housed in each cylinder, and the cylinder 21. The top of the crankshaft 40 and the bottom of the cylinder 22 are respectively combined with a main bearing 25 and an auxiliary bearing 26 for slidingly supporting the crankshaft 40, and a piston (not shown) that reciprocates synchronous...

Embodiment 2

[0063] If there is a non-combined gap between the gap side 31b of the intermediate plate and the cylindrical housing 2a, the purpose can be achieved, so the shape of the gap side 31b does not need to be similar to the shape of the cutout side 6b of the stator core. Figure 5 The middle partition 32 shown in , according to the above considerations, the shape of the gap side 31b is set as a large arc. Therefore, the width of the outer peripheral gap 31c becomes small, and the rigidity of the partition plate 32 increases.

[0064] The buffer hole 33c added between the joint edge 31a and the grinding surface 33a prevents the deformation of the joint edge 31a in contact with the inner circumference of the cylindrical shell 2a from propagating to the grinding surface 33a, and is a means to prevent deformation of the cylinder fixed on the grinding surface 33a. In addition, the buffer hole 33c is also an oil hole that communicates with the inside of the sealed housing 2 and the oil st...

Embodiment 3

[0068] Figure 7 and Figure 8 Embodiment 3 shown in , relates to the welding of the outer periphery of the joining edge 31a of the intermediate partition 32 and the inner periphery of the cylindrical shell 2a. Figure 7 is equipped with Figure 5 A plan view of the compression mechanism part 20 of the shown intermediate partition plate 32 viewed from the side of the second end plate 2c, and figure 1 The Z-Z cross-sectional diagram is equivalent.

[0069] Figure 7 Among them, spot welding 38 is performed at the centers of the four joining sides 31a of the intermediate partition 32 combined with the inner periphery of the cylindrical shell 2a. As in this example, if the joint side 31a is welded by one spot welding, the joint side 31a may be shortened and the gap side 31b may be lengthened.

[0070] Figure 8 , The fixing strength of the compression mechanism part 20 can be further improved by performing two spot weldings 38 on the joint side 31 a having a sufficient arc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com