Inlet/outlet sealing structure of continuous plasma modification device of film strip

A sealing structure, plasma technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve gas sealing problems and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

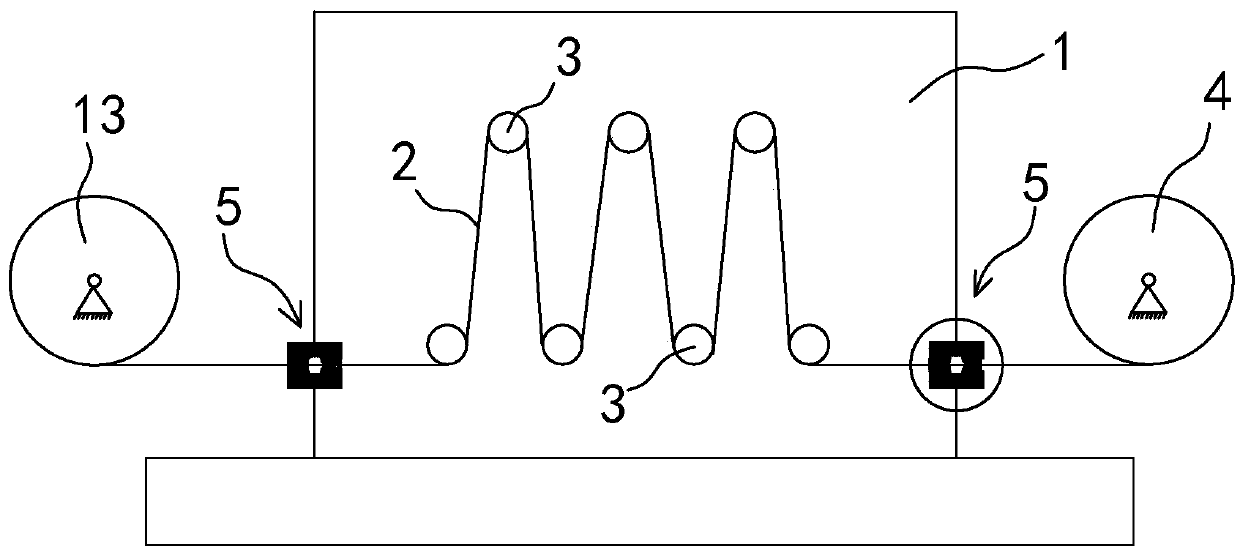

[0025] A sealing structure for the inlet and outlet of a continuous plasma modification device with film strips, see attached figure 1 As shown, the film strip material 2 is discharged on the discharge roller 4, passes through several guide rollers 3 in the modification chamber 1, and finally winds up on the take-up roller 13.

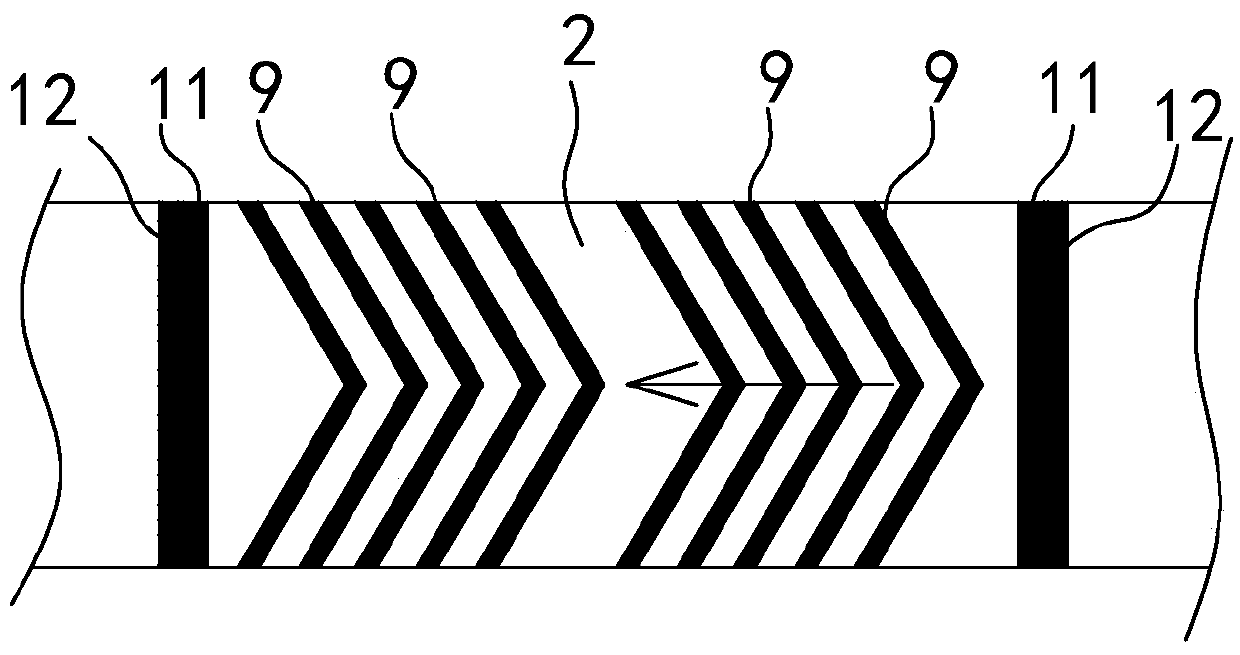

[0026] See attached figure 1 ~ attached image 3 As shown, the inlet and outlet are the inlets and outlets of the modified chamber 1 of the plasma modification device, including the feed inlet and the outlet, both of which are located on the modified chamber 1, and the film belt material 2 Enter the modified bin 1 through the feed port, and output from the modified bin 1 through the discharge port. The moving direction of the film strip material 2 is perpendicular to the radial plane of the feed port and the discharge port, along the Observed from the direction of movement, the inlet and outlet are flat.

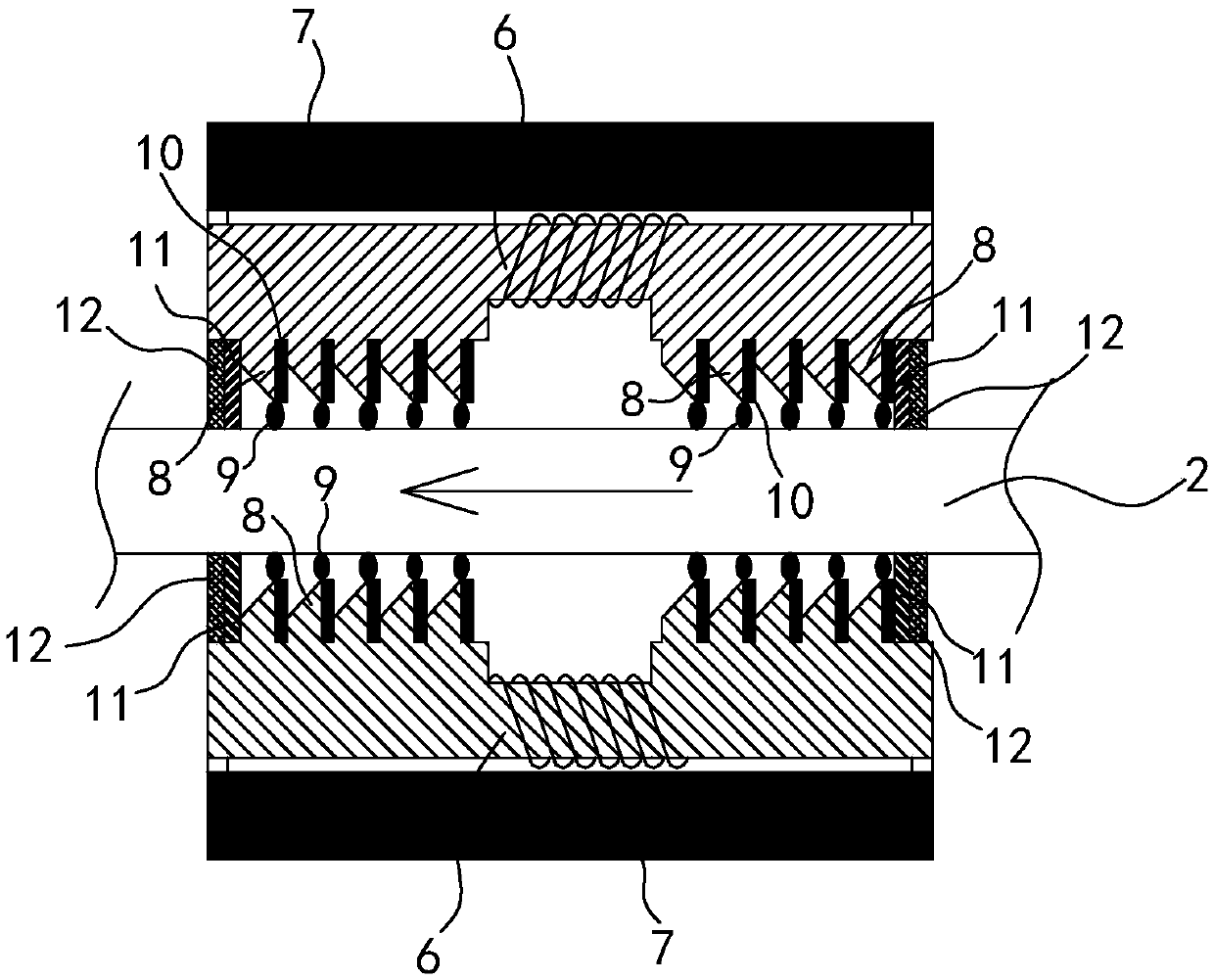

[0027] Both the feed inlet and the discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com