Mechanical slag removing method and device in pulverized coal combustion application of lime sleeve kiln

A pulverized coal combustion and sleeve kiln technology, applied in the field of lime sleeve kiln, can solve the problems of shortening the life of refractory materials in the combustion chamber, high cleaning frequency, safety hazards, etc., so as to avoid untimely slag cleaning, reduce labor costs, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

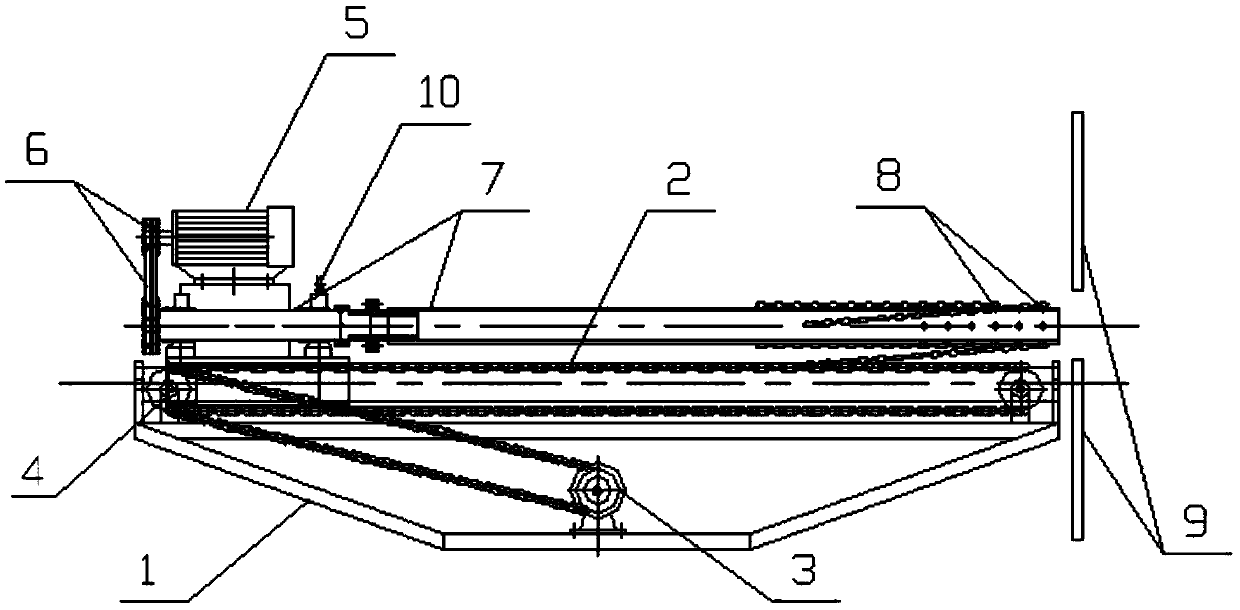

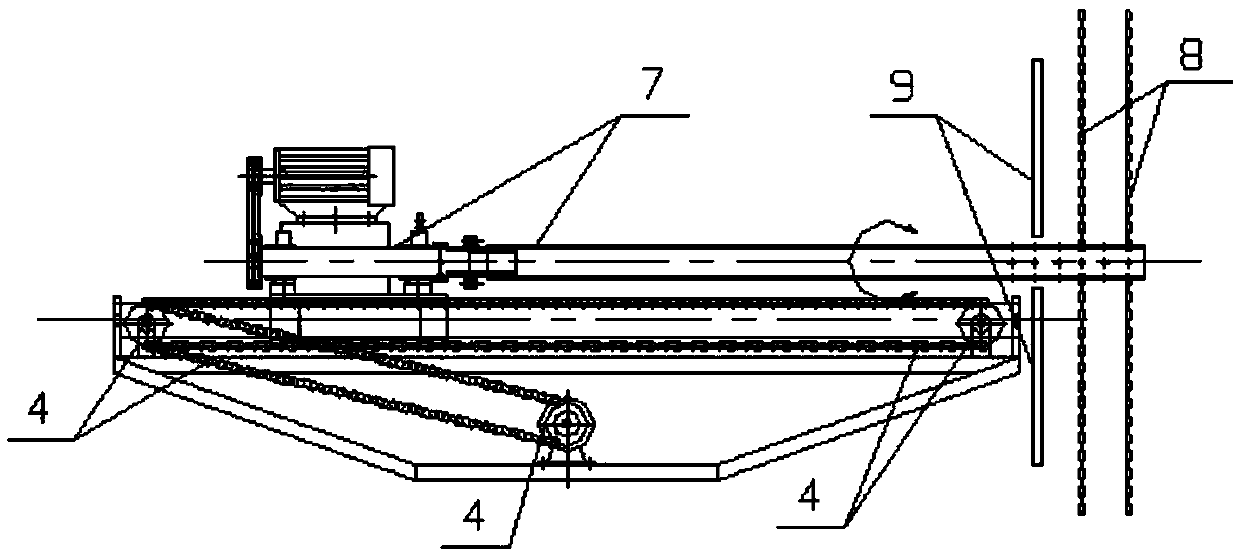

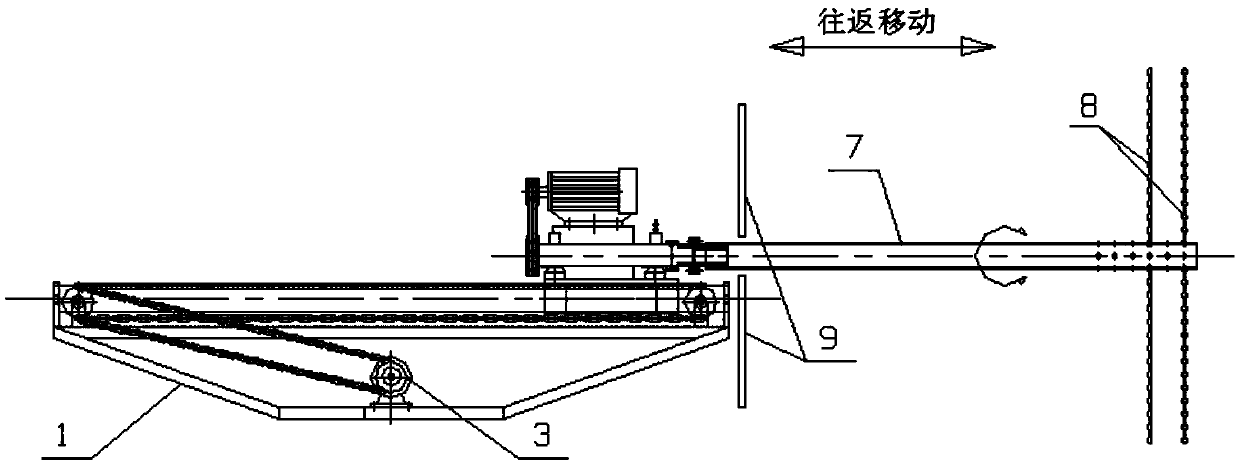

[0025] The present invention will be further explained below in conjunction with the accompanying drawings.

[0026] The present invention relates to a mechanical slag removal method in the application of pulverized coal combustion in a lime sleeve kiln. The mechanical slag removal method is used for cleaning the slagging in the pulverized coal combustion chamber of the lime sleeve kiln, and can not stop the pulverized coal supply in the combustion chamber, Clean the slagging in the combustion chamber under the high temperature condition of normal combustion. The mechanical slag removal method is that the driving device drives the cantilever shaft equipped with the slag removal device to rotate. The slag removal device includes a flexible chain or a steel cable. , Crushing and cleaning slagging. When the wall shaft rotates, the cooling medium can be passed into the center of the cantilever shaft, and the cooling medium is sprayed out through the cooling holes on the cantileve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com