Input and output end spline missing tooth relative angle detection platform

An input and output, relative angle technology, applied in the direction of measuring devices, instruments, etc., can solve the problems that the inspection results cannot be one-to-one correspondence with the products, inconvenient to operate, prone to misjudgment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

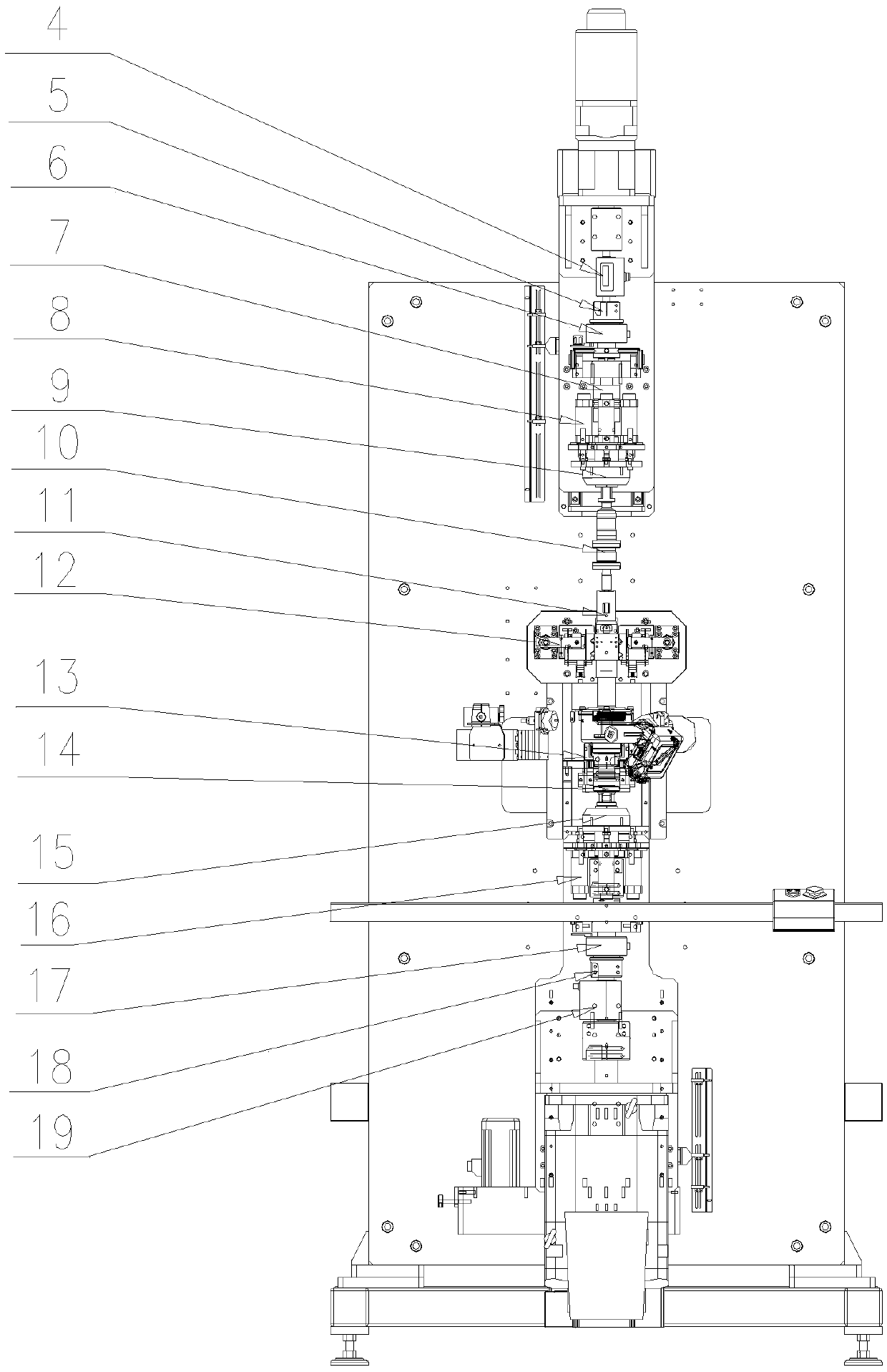

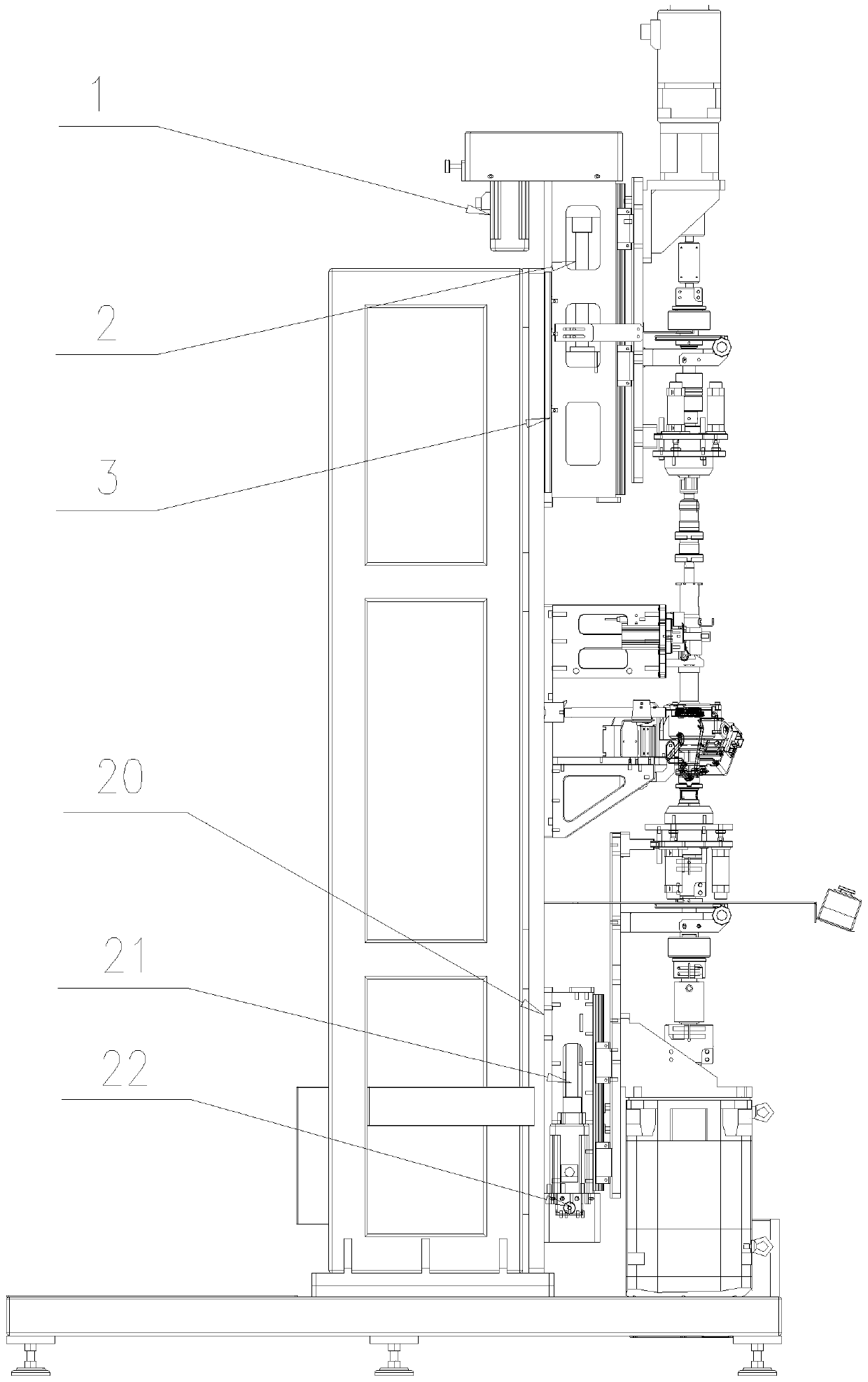

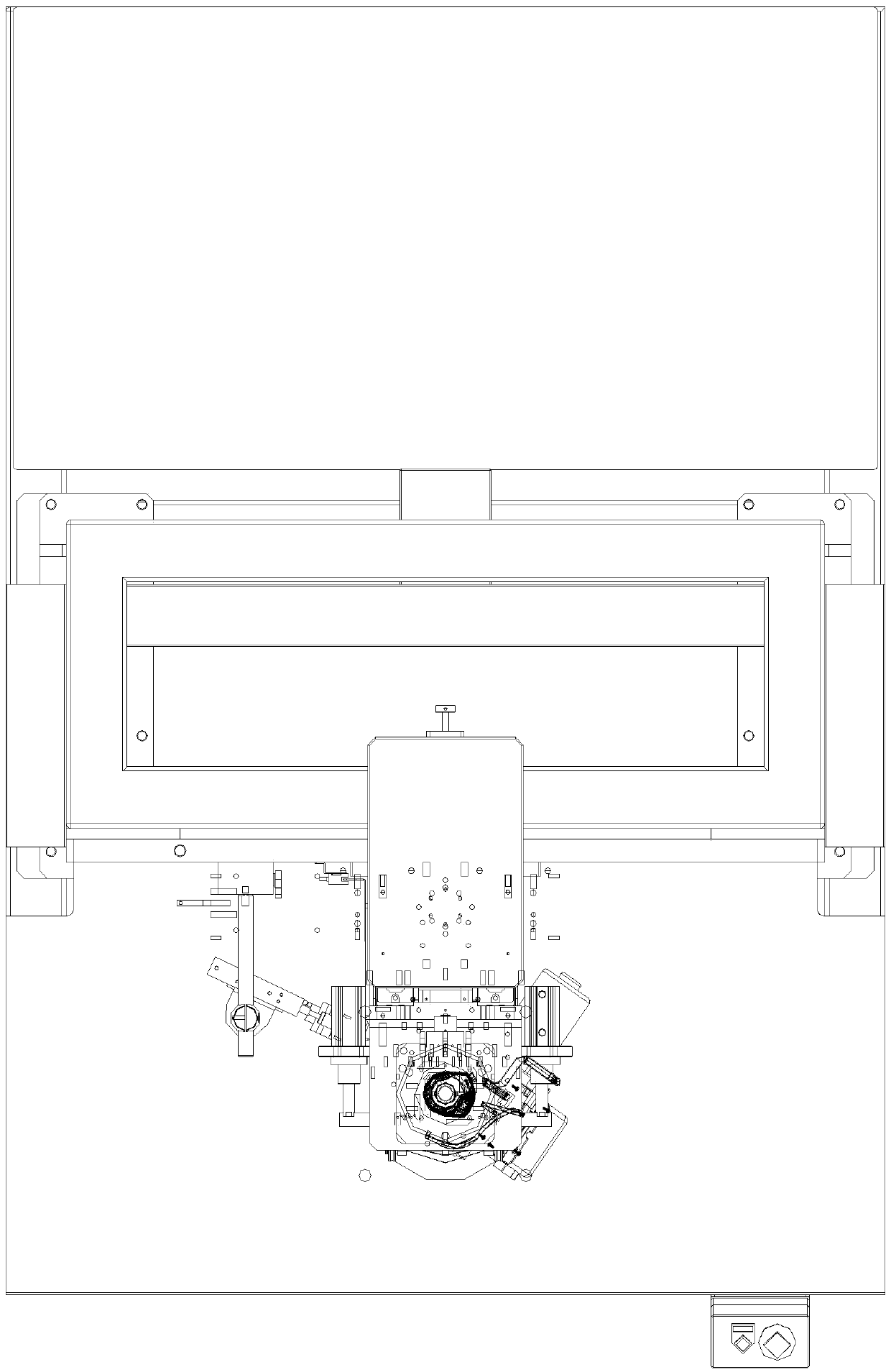

[0017] Such as Figure 1-3 As shown in the present invention, a relative angle detection platform for spline missing teeth at the input and output ends includes a first servo motor, a first ball screw and a first linear guide pair respectively arranged on the upper part of the main frame; the lower part of the main frame There are a first servo motor, a second ball screw and a second linear guide; the first servo motor is connected to the first ball screw; the second servo motor is connected to the second ball screw; the first linear Both the guide rail pair and the second linear guide rail are arranged on the main frame; the first torque sensor, the first shaft coupling, the first angle encoder, and the second coupling are sequentially arranged between the first servo motor and the second servo motor. Shafter, first cylinder, first shrinking chuck, input transition joint, electric steering column, rotary clamping cylinder, positioning tooling, output transition joint, second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com