High-temperature temperature measurement element device with adjustable measuring point positions

A technology of measuring point position and temperature measuring element, which is applied in the field of high temperature temperature measuring element device, can solve the problems of high price of temperature sensing material, affecting engine performance, increasing flow channel blockage ratio, etc., and achieves major social and economic benefits, The effect of reducing impact and reducing measurement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

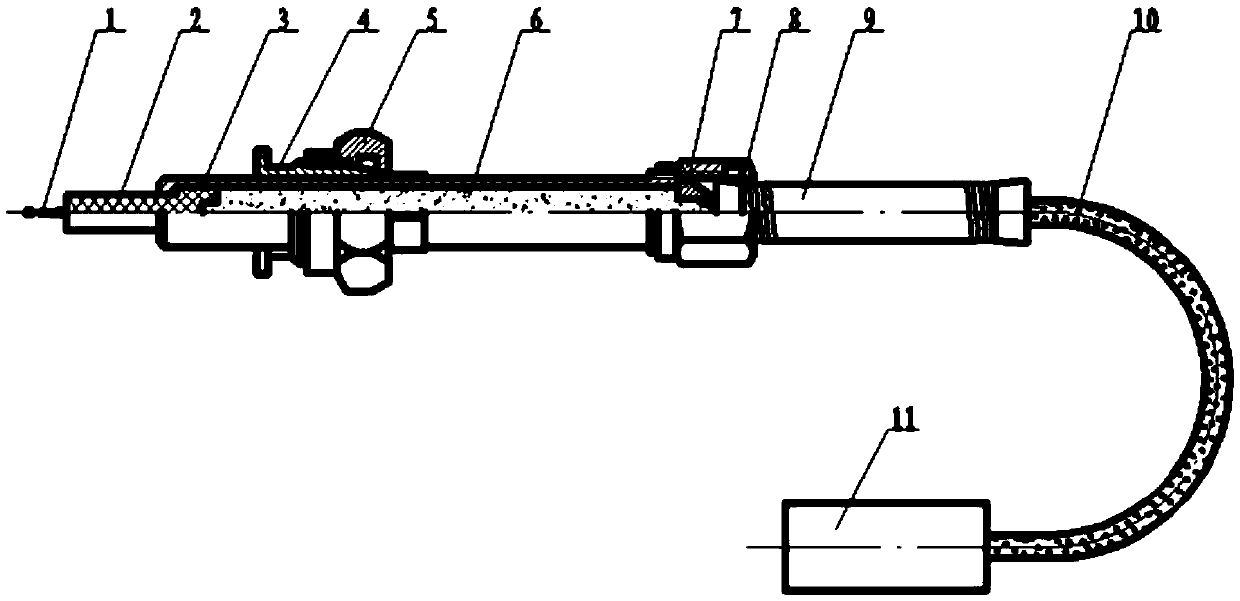

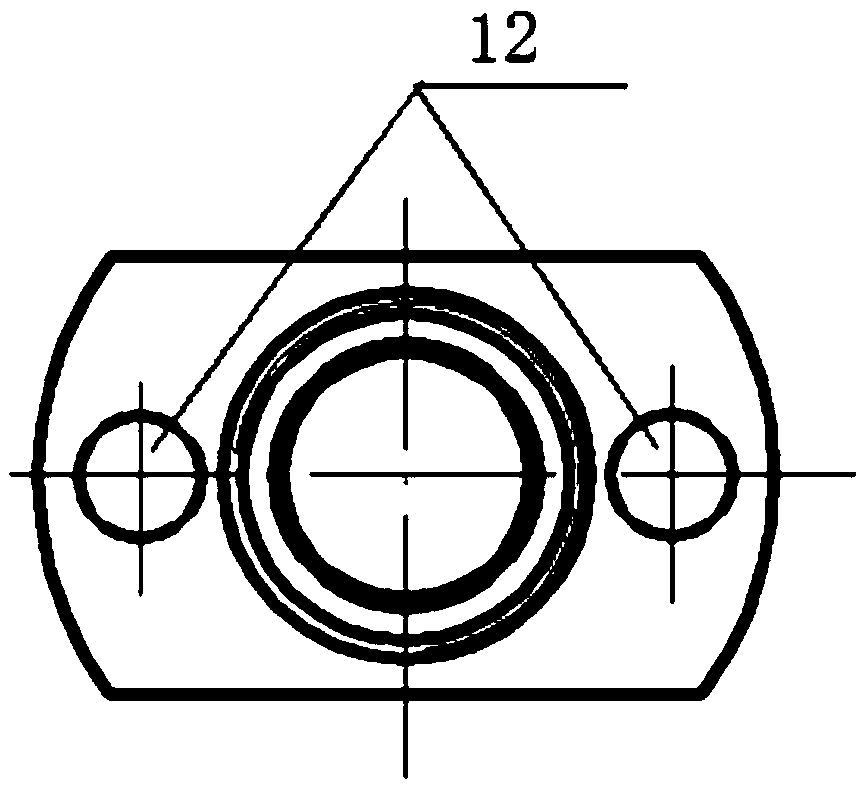

[0021] Such as figure 1 Shown is a high temperature temperature measuring element device that can adjust the position of the measuring point. The device includes a thermocouple 1, a corundum porcelain tube 2, a housing 3, a mounting seat 4, a mounting seat nut 5, hot cement 6, and a fixing clip 7 , fixed clip nut 8, spring tube 9, glass wool casing 10 and aviation electrical connector 11;

[0022] The thermocouple 1 is plugged into the corundum porcelain tube 2, and the corundum porcelain tube 2 equipped with the thermocouple 1 is inserted from one end of the housing 3;

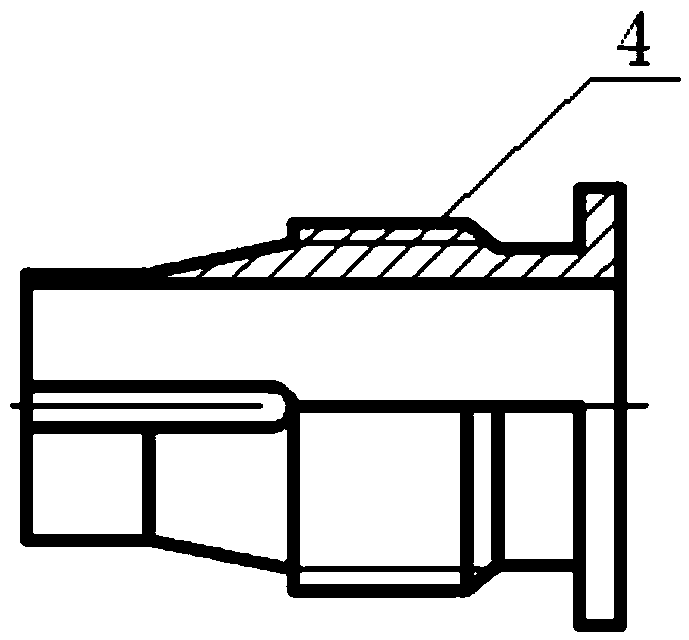

[0023] The other end of the housing 3 is provided with an external thread, and the housing 3 equipped with the thermocouple 1 and the corundum porcelain tube 2 is plugged into the mounting seat 4, and the mounting base 4 is fixed on the housing 3 by installing the nut 5 superior;

[0024] The housing 3 is filled with hot cement 6;

[0025] The part of the thermocouple 1 beyond the housing 3 is penetrated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com