Steeply inclined coal seam horizontal segmentation full-mechanized caving mining simulation experiment table and method

A technology of simulation experiments and experimental methods, applied in the field of mining technology and engineering, can solve problems such as low recovery rate of top coal, difficulty in predicting the flow and migration path of broken top coal, complex roof fracture and mine pressure appearance, etc., to improve The effect of top coal recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical scheme of the experimental platform and experimental method of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

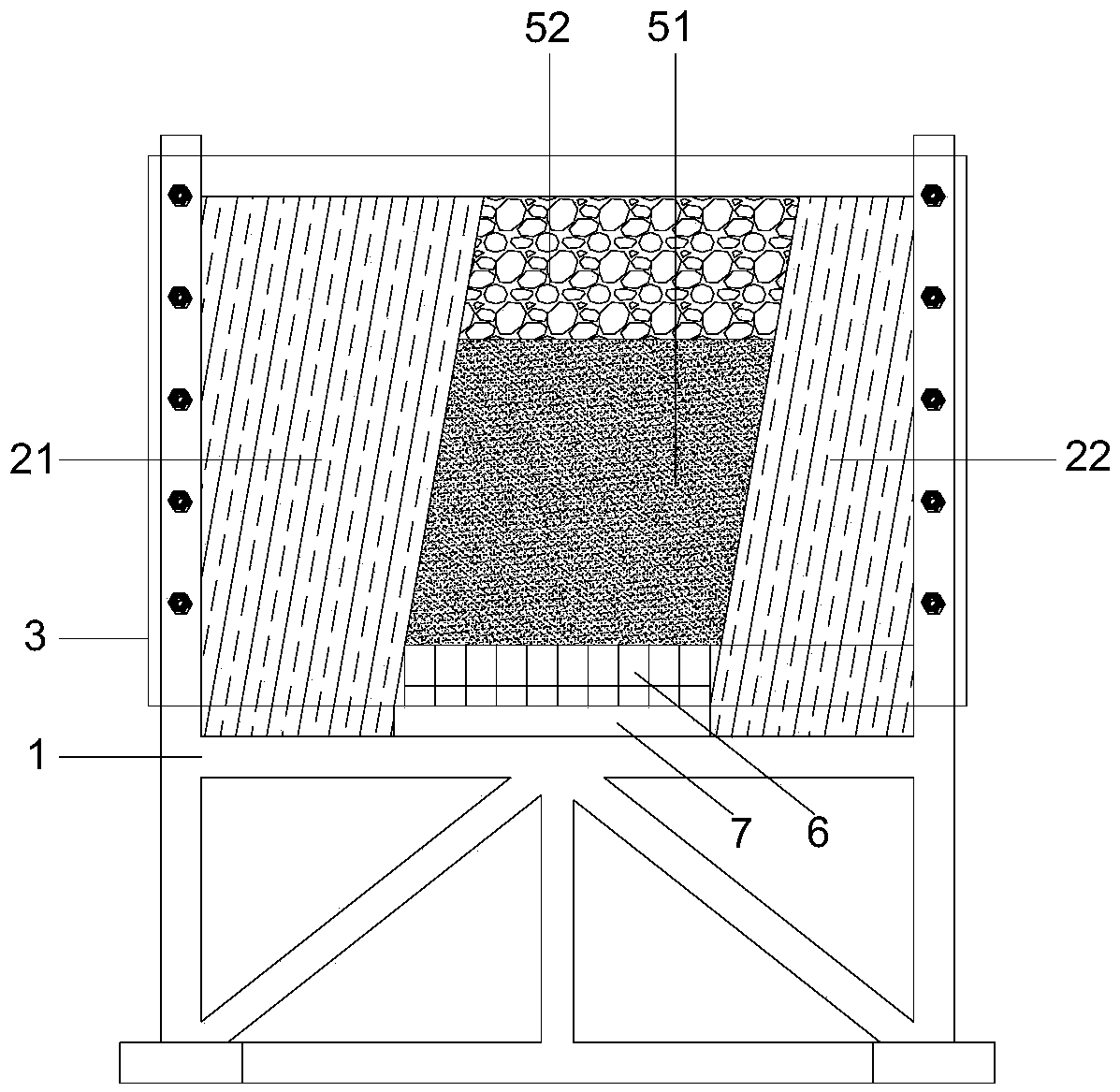

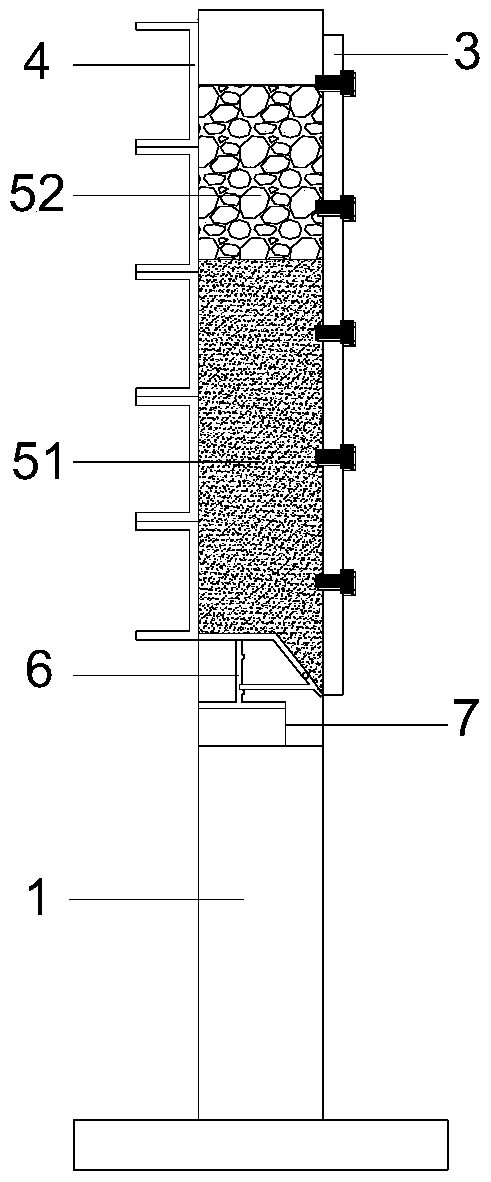

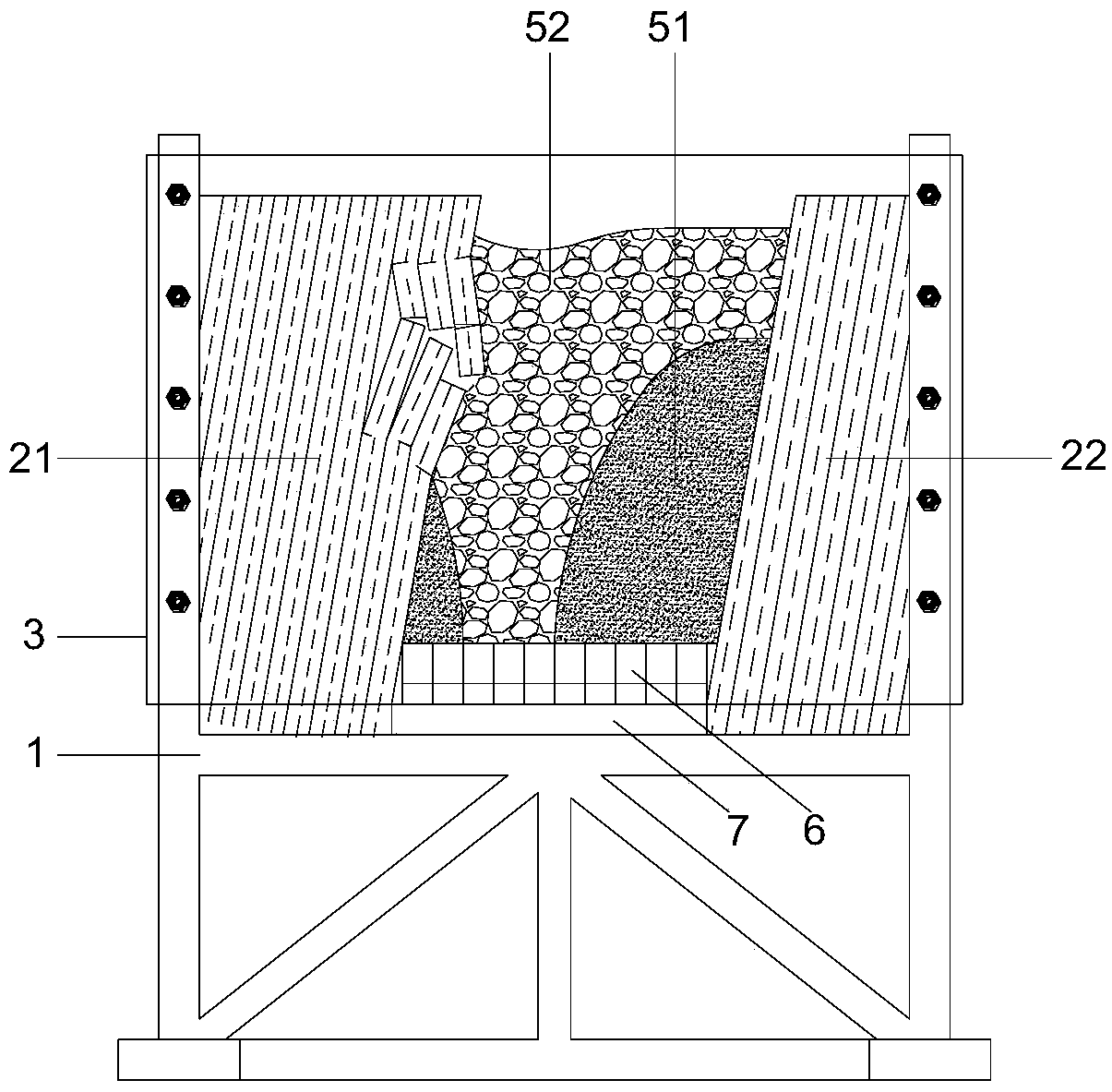

[0021] like figure 1 and figure 2 Shown is a front view and a cross-sectional view of a steeply inclined coal seam horizontal section fully mechanized caving mining simulation test bench and an experimental method, mainly including a test bench body 1, a consolidated body top plate 21, a consolidated body bottom plate 22, organic glass 3, Channel steel 4, bulk crushed top coal 51, bulk goaf gangue 52, coal setting support 6, support base 7. Place the support base 7 and the coal discharge support 6 on the test bench body 1, adjust the ratio of sand, lime, gypsum and water according to the simulated roof and floor strength calculated by the measured parameters and the similarity ratio, Lay the consolidated body top plate 21 and the consolidated body bottom plate 22 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com