Actual measurement sound velocity-based ultrasonic distance measuring method and ultrasonic sensor

A distance measurement method, ultrasonic technology, applied in the direction of sound wave re-radiation, radio wave measurement system, instrument, etc., can solve the problems of unstable measurement and large measurement deviation, and achieve the effect of stable data and reduced interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

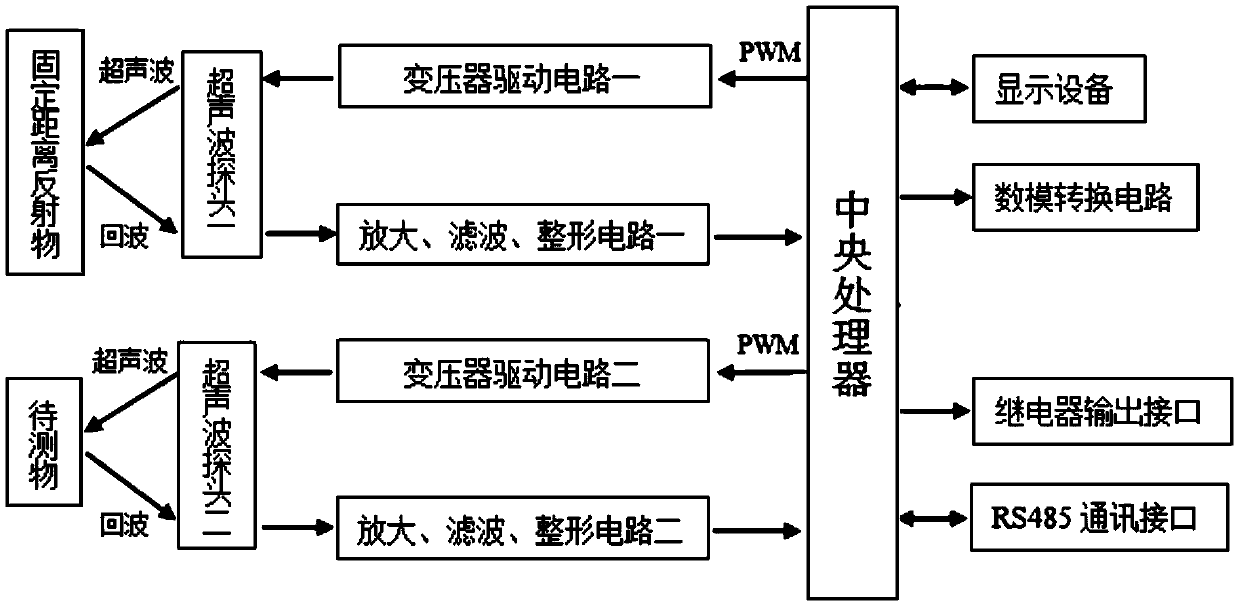

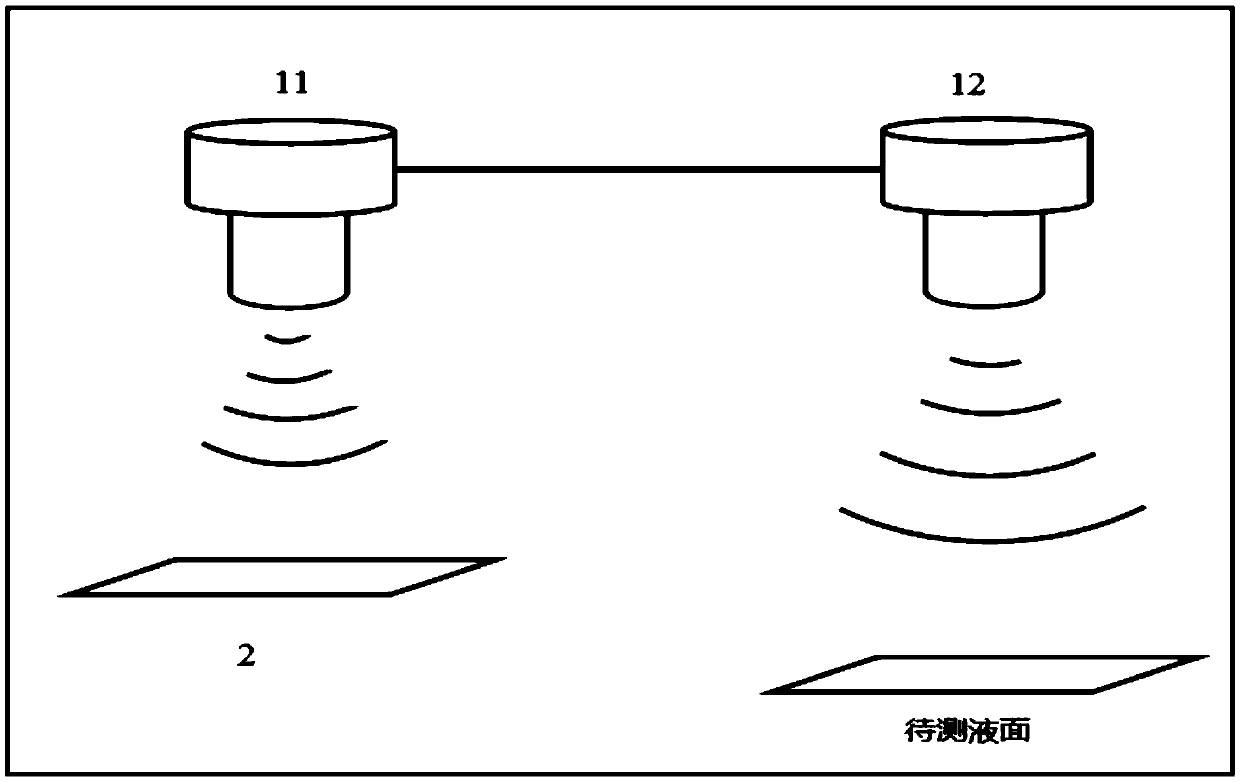

[0077] Such as figure 1 , figure 2 Shown:

[0078] An ultrasonic liquid level transmitter comprises an ultrasonic probe one (velocity measuring probe) 11 and an ultrasonic probe two 12 (distance measuring probe); the ultrasonic probe one 11 is used to measure the actual sound velocity; the ultrasonic probe two 12 is used for measuring the liquid level to be measured distance.

[0079] The central processing unit is respectively connected to the transformer driving circuit one and the amplification, filtering and shaping circuit one, and the central processing unit sends a PWM signal through the transformer driving circuit one to drive the ultrasonic probe one 11 to emit ultrasonic waves, and the ultrasonic waves meet a reflector arranged at a known fixed distance 2 (the reflector can be a baffle) and emit back, the reflected ultrasonic echo is received by the ultrasonic probe-11, and converted into an ultrasonic echo signal, which is amplified and filtered 1. After being p...

Embodiment 2

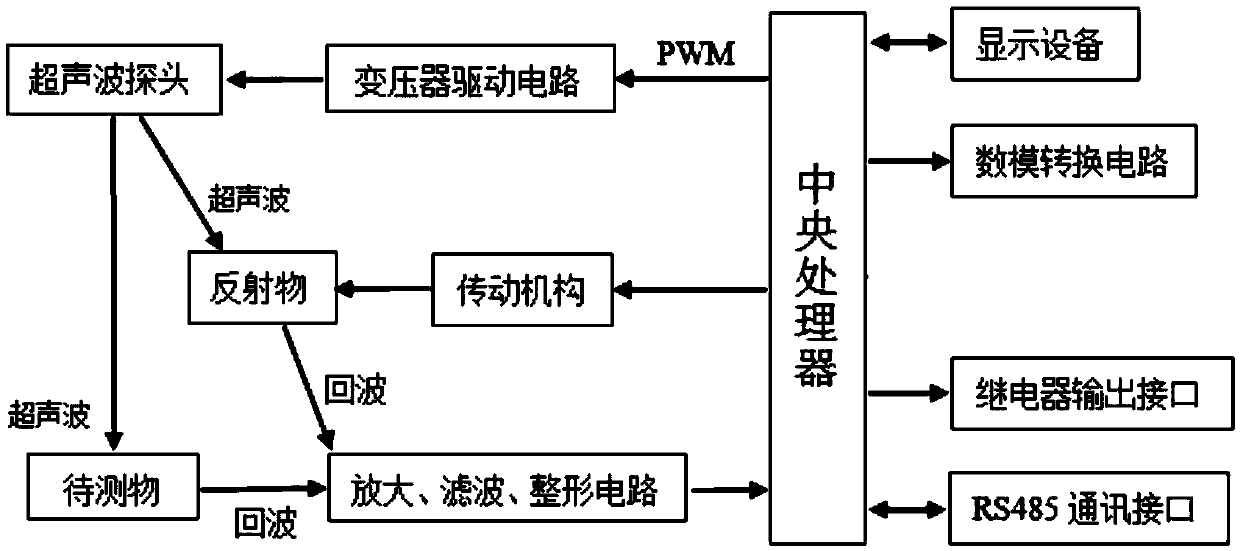

[0103] Such as image 3 , Figure 4 Shown:

[0104] An ultrasonic liquid level transmitter comprises an ultrasonic probe 1' and a central processing unit:

[0105] The central processing unit is connected with a transmission mechanism 3', and the transmission mechanism 3' is connected with a reflector 2' (the reflector can be a baffle);

[0106] The transmission mechanism 3' is used to move the reflector 2' connected to the transmission mechanism 3' directly under the ultrasonic probe 1' after receiving the drive signal sent by the central processing unit, so as to measure the actual speed of sound; the transmission mechanism 3' is also used to receive the retraction signal sent by the central processor after measuring the actual speed of sound, and move the projectile 2' out of the measurement range of the ultrasonic probe;

[0107] The central processing unit is connected to the transformer driving circuit and the amplification, filtering and shaping circuits, and the ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com