Comprehensive analyzing method and apparatus for fracture-vug type carbonate reservoir exhaustion exploitation features

A technology for carbonate reservoirs and depletion mining characteristics, applied in special data processing applications, instruments, electrical digital data processing, etc. To solve problems such as poor adaptability of rock reservoirs, to improve reliability and development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

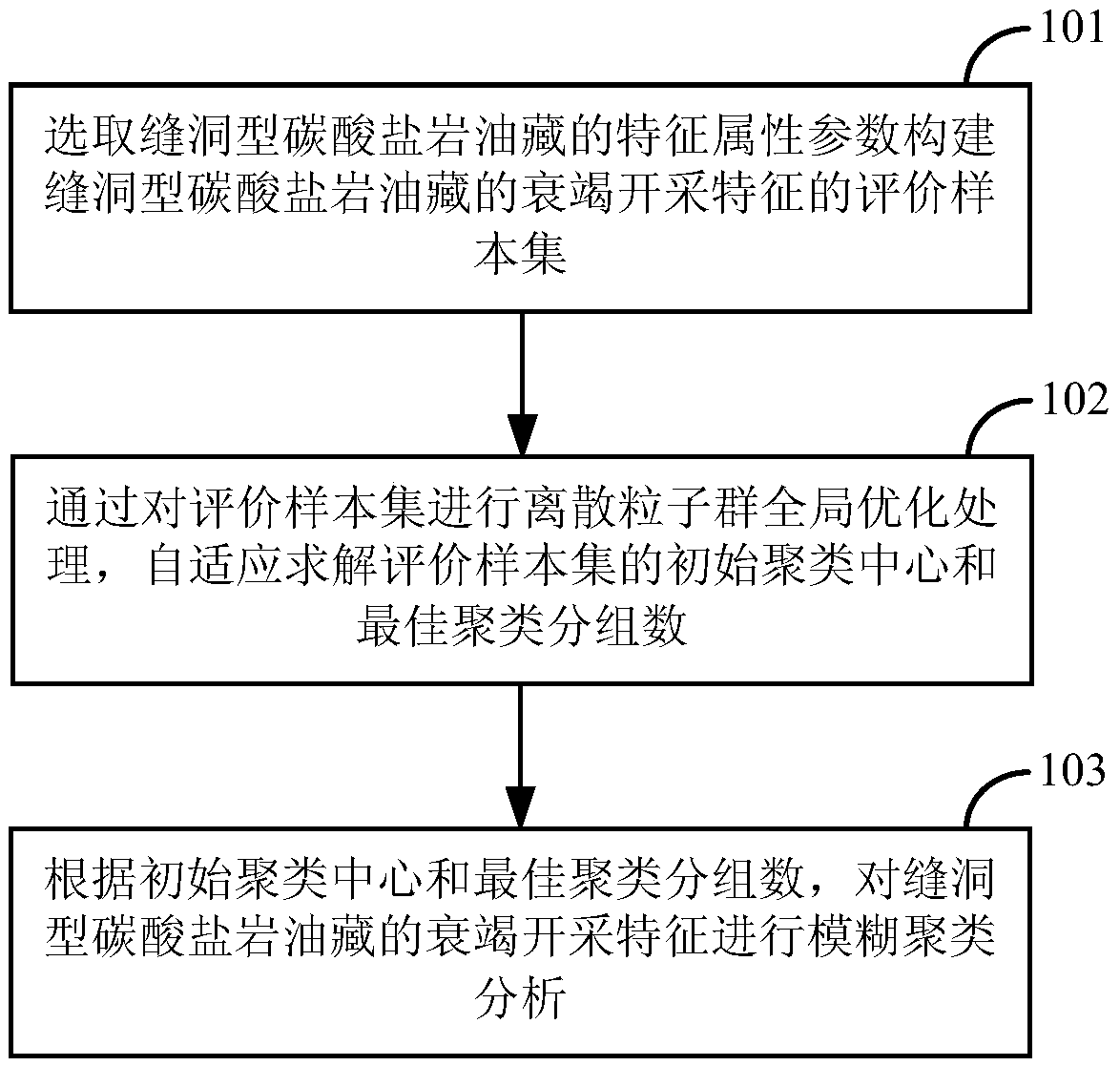

[0026] In order to solve the above problems, the embodiment of the present invention provides a comprehensive analysis method for the depleted production characteristics of fracture-cavity carbonate reservoirs. figure 1 It is a flowchart of a comprehensive analysis method for the depletion and production characteristics of fractured-cavity carbonate reservoirs in the embodiment of the present invention, as figure 1 As shown, the method may include:

[0027] Step 101, selecting characteristic attribute parameters of fractured-vuggy carbonate reservoirs to construct an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com