lLithium battery negative material prepared by compounding spherical nano silicon and graphene and preparing method

A graphene composite, negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the structural basis affecting the high capacity of lithium-ion batteries, the inability to form the ideal gap energy of multi-dimensional stacks, etc., to achieve easy migration. Shuttle, improve the effect of charge-discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

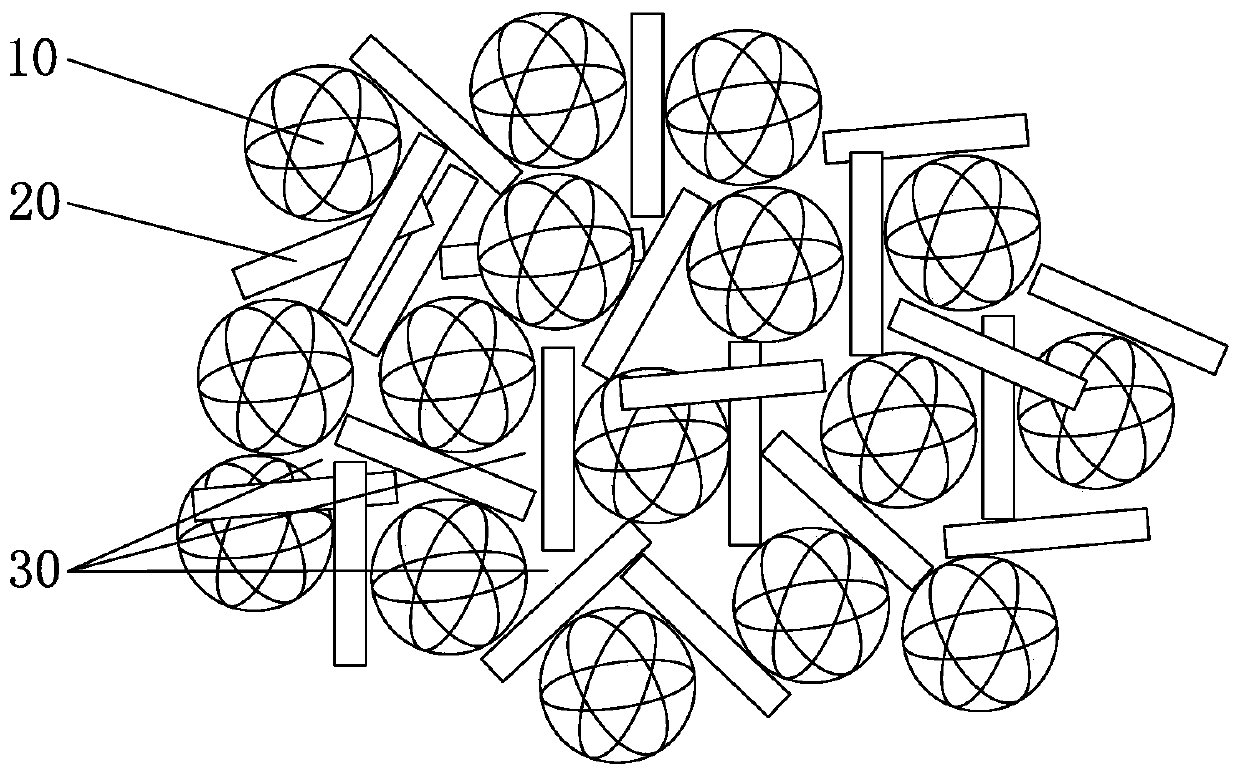

[0020] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 :

[0021] Spherical nano-silicon-graphene composite preparation of lithium battery negative electrode material, spherical nano-metal 10 or spherical nano-metal alloy and 65-97% graphene flat sheet 20, 0.1 Stirring and emulsification of 15% conductive high molecular polymer and 0.1-15% water-soluble adhesive to obtain a lithium battery negative electrode material with laminated multi-dimensional interstitial composite.

[0022] The above-mentioned nano-metal 10 or nano-metal alloy has a particle diameter of 30-300nm, a spherical shape, and a purity of more than 99.95%.

[0023] The graphene flat sheet 20 above is a non-oxidized graphene flat sheet prepared by mechanical ball milling and exfoliation equipment, the thickness of the graphene flat sheet is 0.37-5nm, and the average length is 100-5000nm.

[0024] The above-mentioned conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com