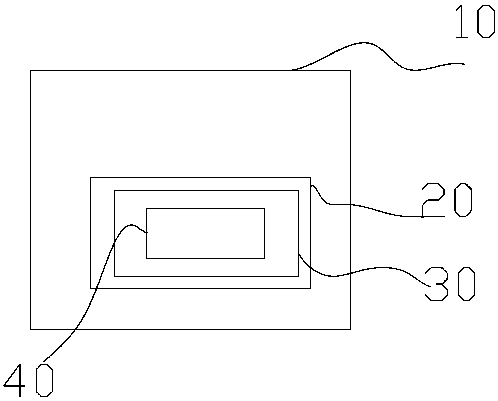

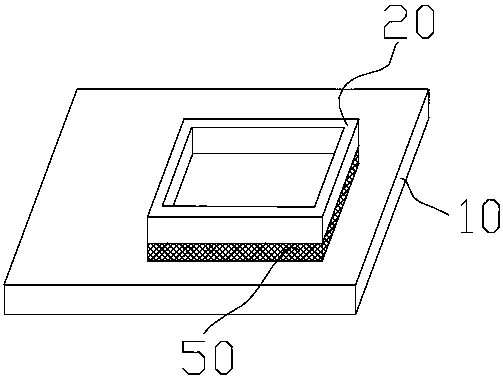

Method of Opening Holes in Convex Ladder Thickened Steel Sheets and Heightening Reflow Soldering Spots

A reflow soldering and ladder technology, applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve the problems of poor accuracy and consistency, high defect rate and rework rate, and the inability to achieve 0.5mm height solder joints, etc., to improve The effect of qualified rate, reducing heat treatment process and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 0603PAD, the target PAD height is 0.30mm, the thickness of the bottom steel mesh is 0.13mm, and the thickness of the convex stepped steel sheet is 0.15mm.

[0057] 1) Calculate the enlarged side area S=2.01mm 2

[0058] 2) L:W=L':W'=0.83:0.8=1.03

[0059] 3) Take W: 1.40mm, then L=1.43mm

[0060] If the equal width method is used to enlarge, then the first enlarged length L1=the second enlarged length L2.

Embodiment 2

[0062] 0805PAD, the target PAD height is 0.50mm, the thickness of the bottom steel mesh is 0.13mm, and the thickness of the convex stepped sheet is 0.15mm.

[0063] 1) Calculate the enlarged side area S to be 8.48mm 2

[0064] 2) L:W=L':W'=1.4:1.2=1.17

[0065] 3) Take W=2.69mm, then L=3.16mm

[0066] Because there are other devices on one side of the 0805PAD, if there is not enough tin printing area, the one-side enlargement method is adopted, and the first enlargement length L1>the second enlargement length L2.

[0067] As can be seen from the above, the method for increasing the height of the reflow solder joints by opening holes in the convex stepped thickened steel sheets of the present invention, and the method for increasing the height of the reflow solder joints by opening holes in the thickened steel sheets of the convex steps, through the thickened steel sheets of the convex steps, Changing manual tinning to machine tinning improves production efficiency and produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com