Preparation method and application of a cigarette filter additive

A technology of cigarette filters and additives, which is applied in applications, e-liquid filter elements, tobacco, etc., can solve problems such as the influence of tobacco aroma and uncoordinated cigarette smoke, reduce production costs, solve the problem of smoke coordination, tobacco The outstanding effect of this fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

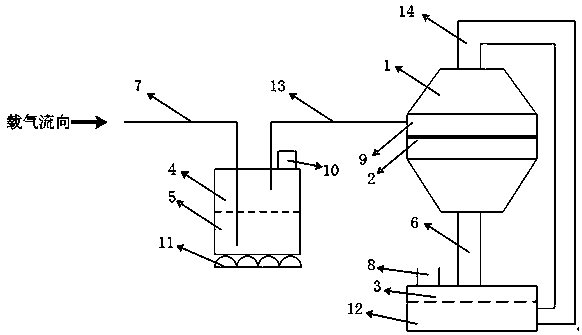

Image

Examples

Embodiment 1

[0030] (1) Put 20g of Zimbabwean tobacco leaves into the pyrolysis reactor, and place 500g of 40-mesh activated carbon particles on the deposition bed below;

[0031] (2) Select nitrogen as the carrier gas flow, control the flow rate of the carrier gas flow to 120ml / min, and pass through the reservoir containing geraniol, wherein the temperature of the reservoir is controlled at 50°C, and use the nitrogen carrier gas flow to bring geraniol into the cracking reactor;

[0032] (3) Turn on the pyrolysis reaction furnace to carry out synergistic pyrolysis reaction of various substances in the furnace, control the pyrolysis temperature to 800°C, the heating rate to 300°C / min, and the pyrolysis reaction time to 5min;

[0033] (4) After the cracking reaction is completed, take out the activated carbon granular material in the sedimentation bed, add it into the cigarette filter after cooling, and the dosage is 10mg / cigarette.

[0034] The final cigarette product has outstanding tobac...

Embodiment 2

[0036] (1) Put 10g of agarwood chips into the pyrolysis reaction furnace, and place 700g of activated carbon particles with a size of 50 mesh on the deposition bed below;

[0037] (2) Select nitrogen as the carrier gas flow, control the flow rate of the carrier gas flow to 60ml / min, and pass through the reservoir containing rose essential oil, and the temperature of the reservoir is controlled at 60°C. The rose essential oil is brought into the pyrolysis reactor by utilizing the nitrogen-carrying air flow;

[0038] (3) Turn on the pyrolysis reaction furnace to carry out a synergistic pyrolysis reaction of various substances in the furnace, control the pyrolysis temperature to 700°C, the heating rate to 200°C / min, and the pyrolysis reaction time to 10min;

[0039] (4) After the cracking reaction is completed, take out the activated carbon granular material in the sedimentation bed, add it into the cigarette filter after cooling, and the dosage is 10mg / cigarette.

[0040] The f...

Embodiment 3

[0042] (1) Put 30g of crushed tea leaves and Zimbabwean tobacco leaves (each accounting for 50%) into the pyrolysis reactor, and place 1000g of 40-mesh activated carbon particles on the deposition bed below;

[0043] (2) Select nitrogen-oxygen mixed gas containing 10% (volume fraction) of nitrogen as the carrier gas flow, control the flow rate of the carrier gas flow to 300ml / min, and directly enter the cracking furnace after passing through the empty liquid storage tank;

[0044] (3) Turn on the pyrolysis reaction furnace to carry out synergistic pyrolysis reaction of various substances in the furnace, control the pyrolysis temperature to 600°C, the heating rate to 400°C / min, and the pyrolysis reaction time to 10min;

[0045] (4) After the cracking reaction is completed, take out the activated carbon granular material in the sedimentation bed, add it into the cigarette filter after cooling, and the dosage is 5mg / cigarette.

[0046] The final cigarette product has outstanding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com