Seven-shaft robot with transverse moving mechanism

A technology of lateral movement and robotics, applied in the field of seven-axis robots, which can solve the problems of narrow control range, difficult horizontal linear movement of the gripper and suction cup, and easy shaking of the manipulator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

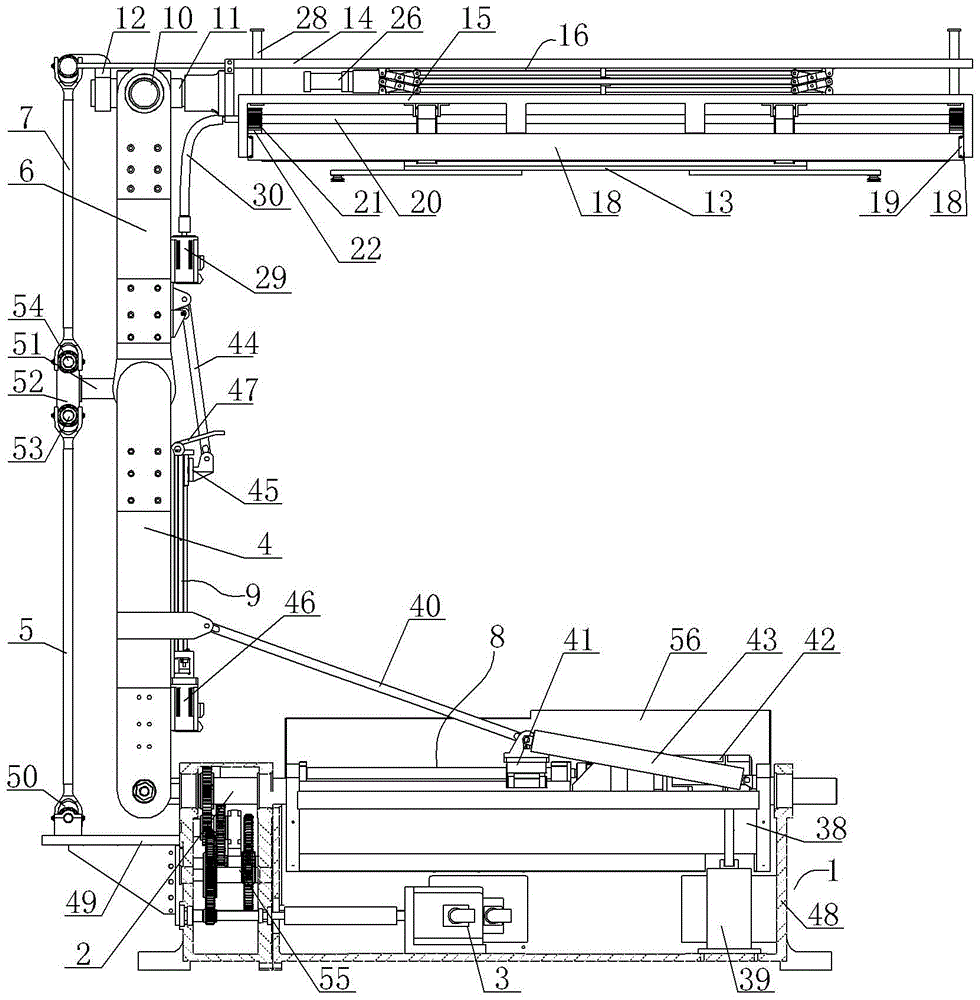

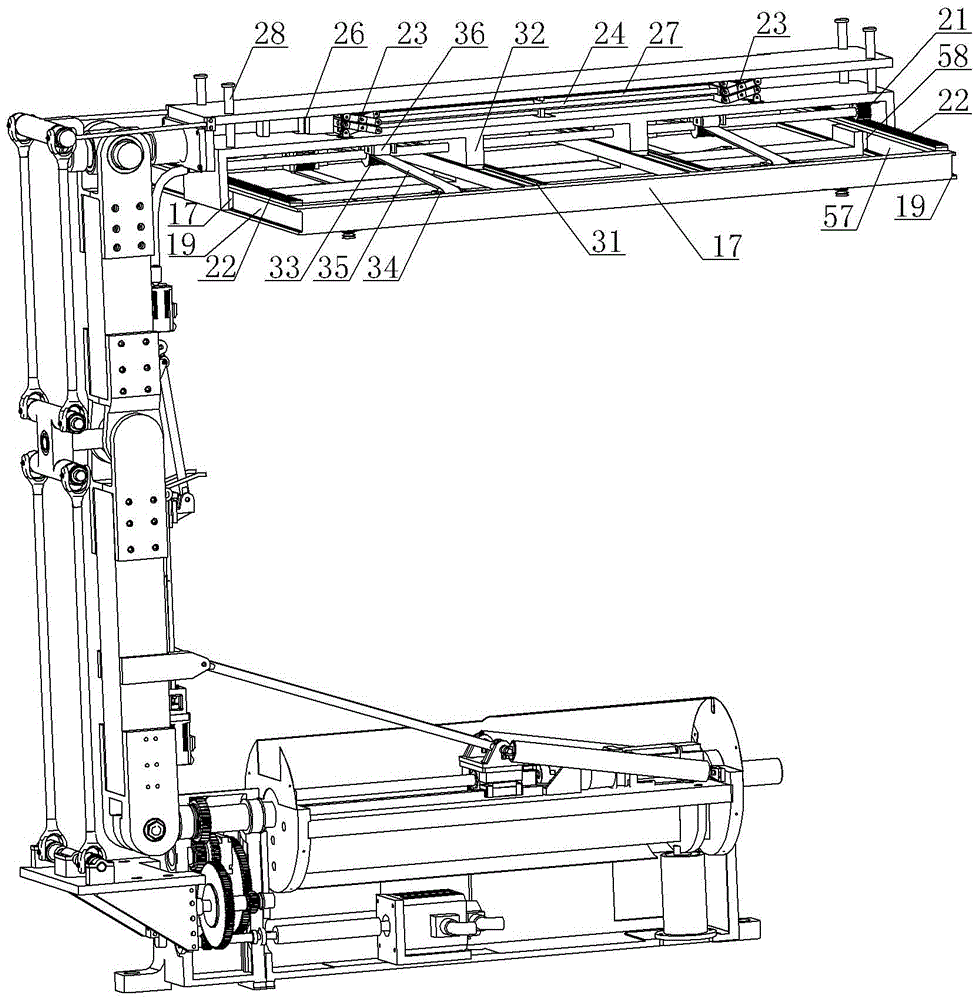

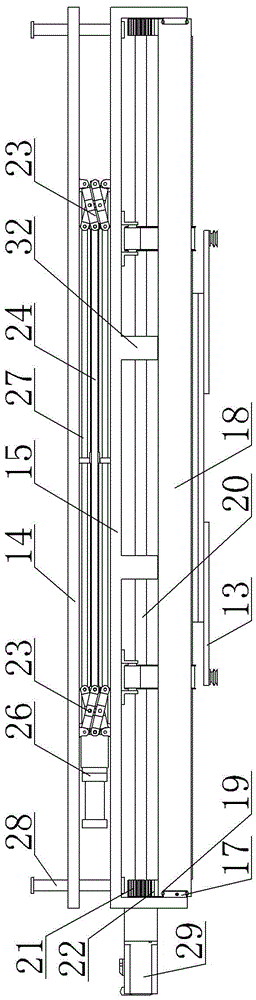

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0038] A seven-axis robot with lateral kinematics, see Figure 1 to Figure 7 : It includes a base 1, the base 1 is provided with a horizontally rotatable first shaft 2, one end of the first shaft 2 is provided with a first shaft servo motor 3 that drives the first shaft 2 to rotate, and the other end of the first shaft 2 is connected to There is a swing arm assembly, the first shaft servo motor 3 drives the first shaft 2 to rotate and then drives the swing arm assembly to swing around the first shaft 2 in the circumferential direction, the free end of the swing arm assembly is connected with a gripper for grabbing workpieces, The swing arm assembly includes a first swing arm assembly and a second swing arm assembly hinged together, the first swing arm assembly includes a second shaft 4 hinged at the end of the first shaft, one side of the second shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com