Apparatus used for turning over blocky objects

An object and block technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of low work efficiency, high work intensity of workers, and large space occupied by the turning device, so as to reduce working time, save turning space, and reduce occupied area. area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

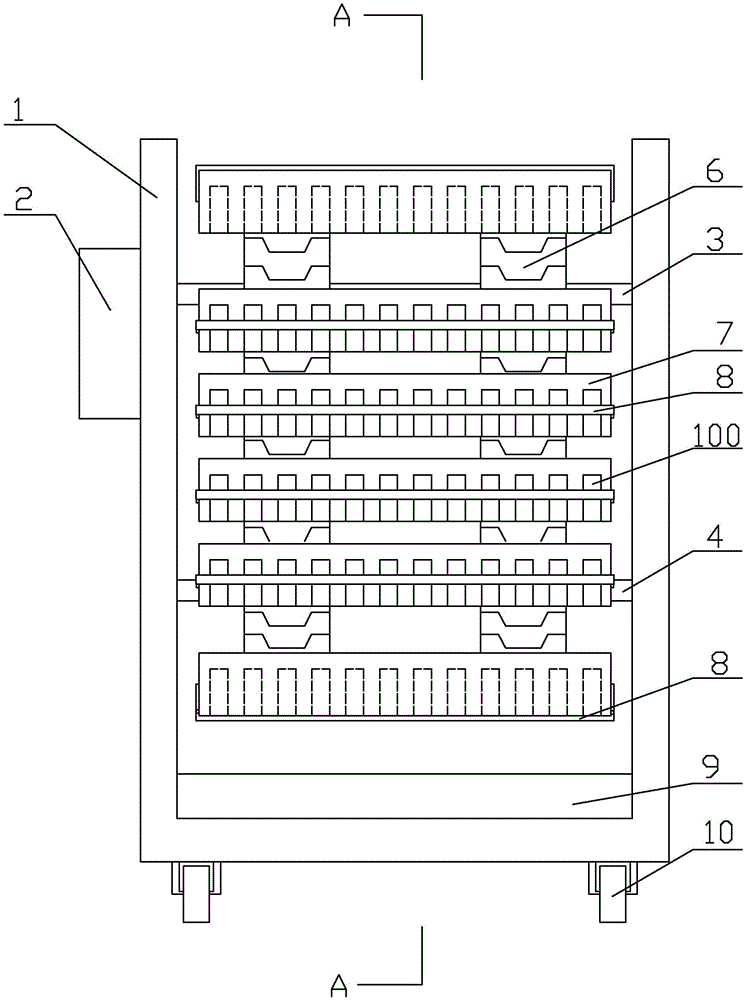

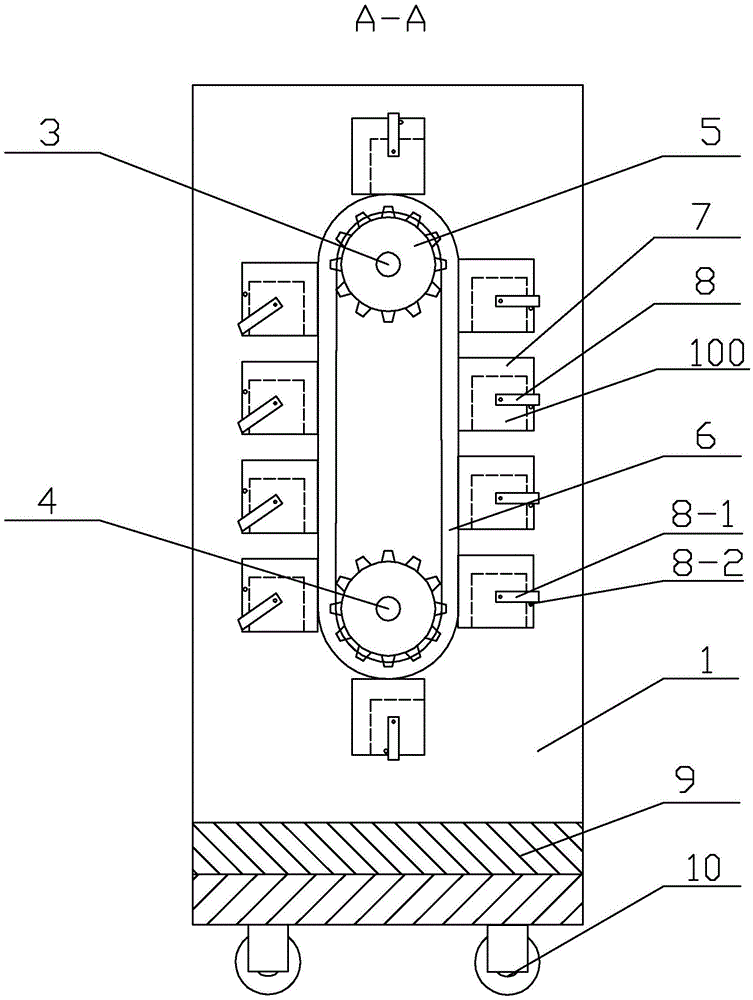

[0012] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a device for overturning a block-shaped object in this embodiment, including a frame 1, a driving device 2, a rotating shaft 3, an optical shaft 4, four gears 5, two guide chains 6 and several storage units 7,

[0013] The rotating shaft 3 and the optical axis 4 are installed in the frame 1 and the rotating shaft 3 and the optical axis 4 are arranged in parallel up and down. The driving device 2 is fixedly connected to one end of the rotating shaft 3. The two guide chains 6 are all meshed with a gear on the rotating shaft 3 and a gear on the optical axis 4. The two guide chains 6 are arranged vertically and parallel to each other. Several storage units 7 are fixed on the guide chains 6 in turn. The objects 100 are located in the storage units 7 , and each storage unit 7 is provided with an anti-falling device 8 .

[0014] The frame is U-shaped, and the baffles on both sides ar...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 with figure 2 To illustrate this embodiment, several storage units 7 are evenly distributed and fixed on the guide chain 6 . Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, each storage unit 7 is fixedly connected to two guide chains 6, and the storage units 7 are arranged horizontally. Such a design increases the stability of the storage unit 7 when it is overturned, so that the block-shaped object 100 inside will not fall due to the instability of the storage unit 7 when it moves around the gear. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0021] Specific implementation mode four: combination figure 1 with figure 2 To illustrate this embodiment, the anti-dropping device 8 includes an anti-tripping 8-1 and a positioning pin 8-2. The anti-tripping 8-1 is rotatably fixed on both sides of the opening end of the storage unit 7, and the anti-tripping 8-1 1 is arranged horizontally, and the positioning pin 8-2 is located on one side of the anti-tripping 8-1 and is fixedly connected to the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com