Pipe rod dragging method and device

A technology of dragging device and pipe rod, applied in drill pipe, drill pipe, casing and other directions, can solve the problems of high labor intensity of workers and large weight of pipe rod, etc., to improve the reliability of locking, reduce labor intensity, and facilitate the removed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

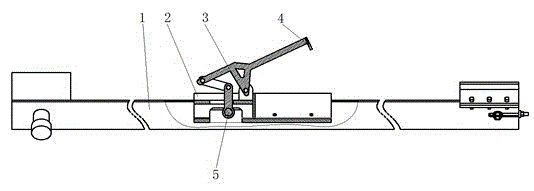

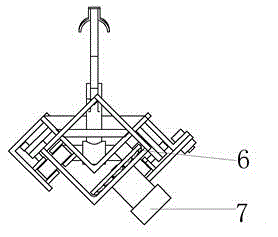

[0016] according to Figure 1-2 , a pipe rod dragging device, including a slideway 1, a trolley 2, a locking mechanism 3, a gripper 4, a sliding pin 5, and traction and power components. The trolley 2 is installed in the slideway 1 and can slide freely relative to the slideway 1. Wherein traction mechanism is sprocket wheel chain mechanism 6, and it directly links to each other with sliding pin 5, and sliding pin 5 is installed in the middle groove of trolley 2, and can have relative motion with trolley. The buckle-lock link mechanism 3 is respectively hinged with the slide pin 5 and the trolley 2, and can complete the snap-lock action through the relative motion of the slide pin 5 and the trolley 2. The gripper 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com