Exhaust gas treatment device

An exhaust gas treatment device and exhaust gas treatment technology, which are applied in the electrical control of exhaust treatment devices, exhaust gas treatment, gas treatment, etc., can solve the problems of untreated exhaust gas, inaccurate measurement signals, and cumbersome structure of exhaust gas treatment boxes, etc. , to achieve the effect of simplified structure and accurate measurement signal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

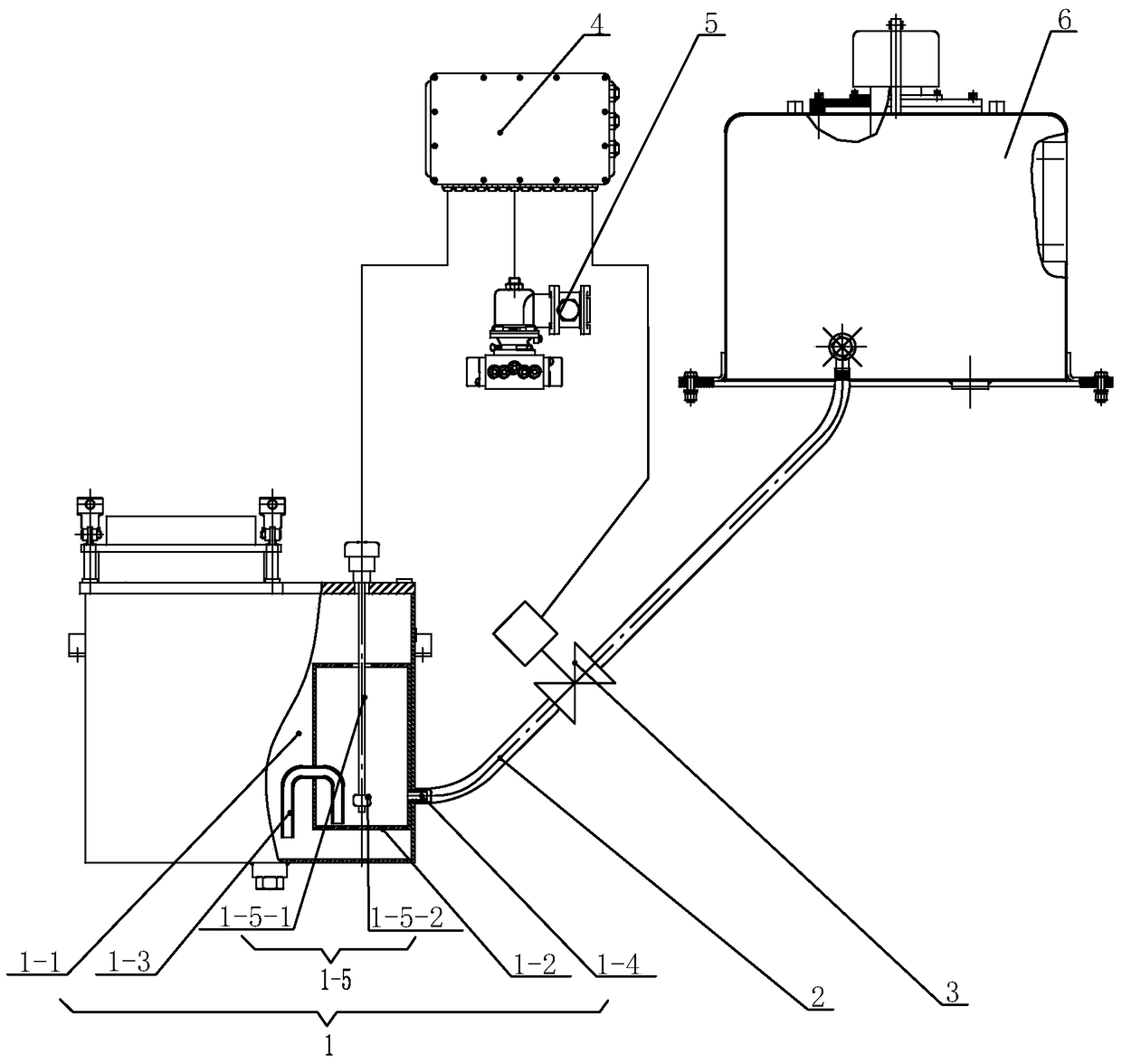

[0009] See figure 1 , an exhaust gas treatment device, comprising an exhaust gas treatment box 1, a water replenishment pipe 2, a water solenoid valve 3, a monitoring host 4, a flameout cylinder solenoid valve 5 and a water replenishment tank 6. The exhaust gas treatment tank 1 includes a large water tank 1-1 and a small water tank 1-2, the small water tank 1-2 is located in the large water tank 1-1, and the small water tank 1-2 and the large water tank 1-1 are connected by a siphon 1-3, When the water level in the small water tank 1-2 is higher than the water level in the large water tank 1-1, the water in the small water tank 1-2 is filled into the large water tank 1-1 through the siphon 1-3, and the top surface of the large water tank 1-1 is fixed A water level sensor 1-5, the detection tube 1-5-1 and the float 1-5-2 of the water level sensor 1-5 are inserted in the small water tank 1-2, and the float 1-5-2 is inserted into the small water tank 1-2 The water level slides u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com