Anti-explosion sprinkling truck

A sprinkler and water pump technology, which is applied in dust prevention, fire prevention, mining equipment, etc., can solve the problems of untreated waste gas, inaccurate measurement signals, and substandard water level in large water tanks, and achieve simplified structure and accurate measurement signals , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

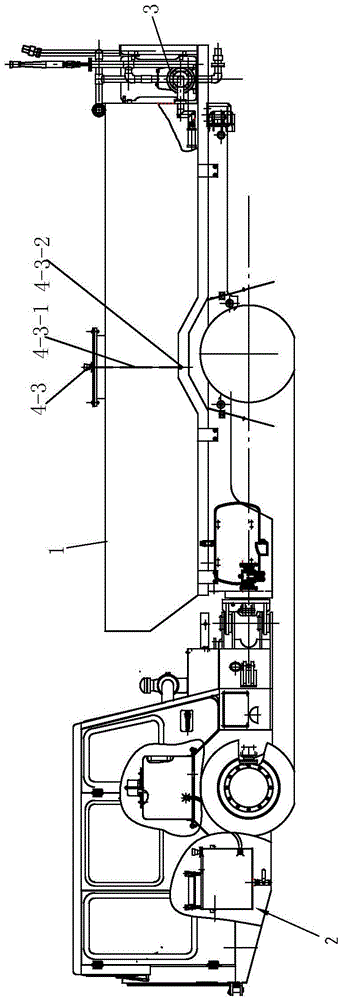

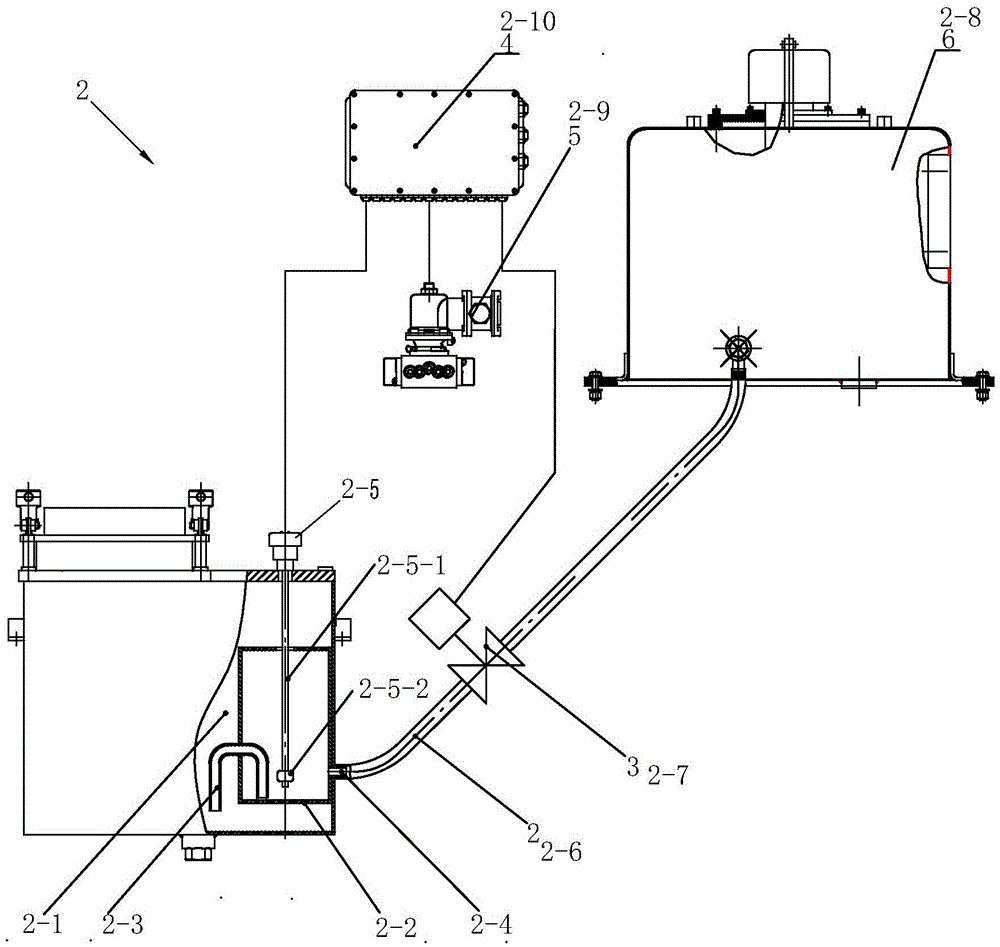

[0013] See Figure 1-2 , this embodiment includes a front frame, a rear frame, a main water tank 1, an exhaust gas treatment device 2, a water pump 3 and a water pump control system 4.

[0014] The front and rear frames are hinged, the exhaust gas treatment device 2 is arranged on the front frame, the main water tank 1 is arranged on the rear frame, and the water pump 3 is connected to the outlet pipe of the main water tank 1 .

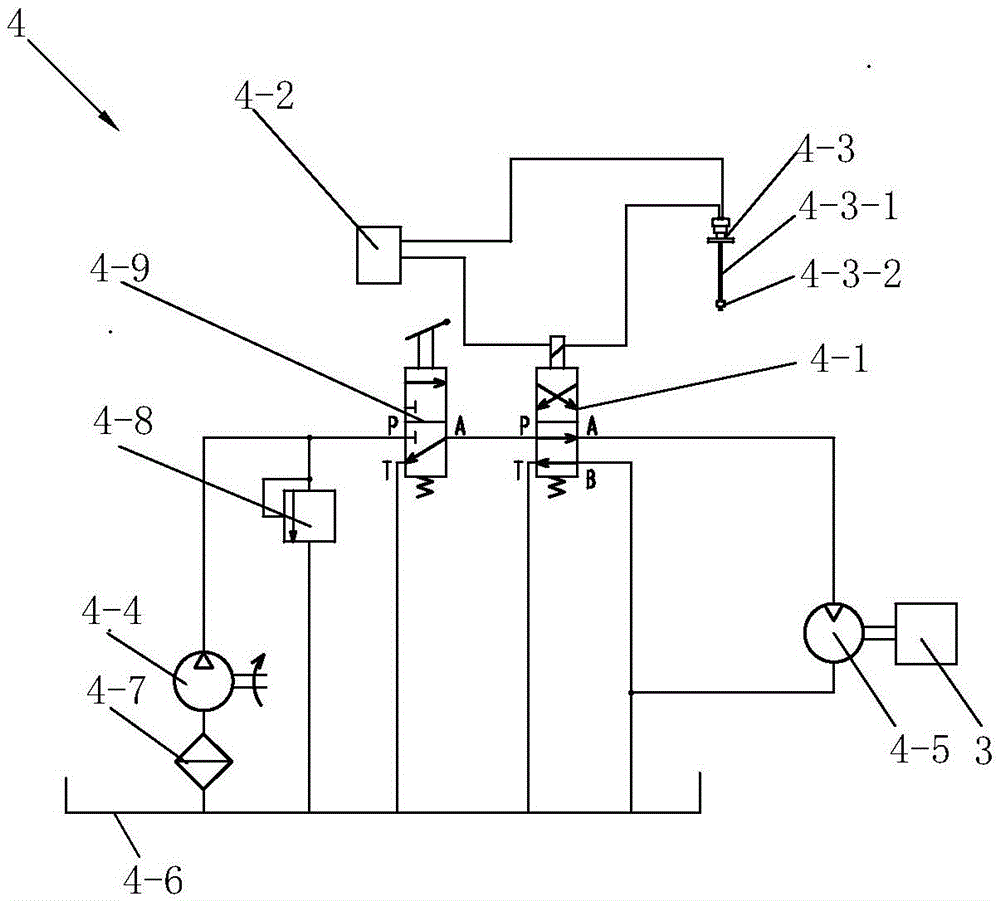

[0015] The water pump control system 4 includes a water pump solenoid valve 4-1, an explosion-proof power supply 4-2, a liquid level switch 4-3, a hydraulic pump 4-4, a hydraulic motor 4-5, an oil tank 4-6, a filter 4-7, an overflow Flow valve 4-8, manual reversing valve 4-9. The liquid level switch 4-3 is installed in the middle part of the top of the main water tank 1. Since the manhole of the main water tank 1 is generally arranged in the middle part of the top, the present embodiment just installs the liquid level switch 4-3 on the manhole cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com