Cleaning machine structure

A cleaning machine and machine body technology, which is applied to cleaning machines, carpet sweepers, carpet cleaning, etc., can solve problems such as deficiencies, and achieve the effects of reasonable structure, good cleaning effect, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

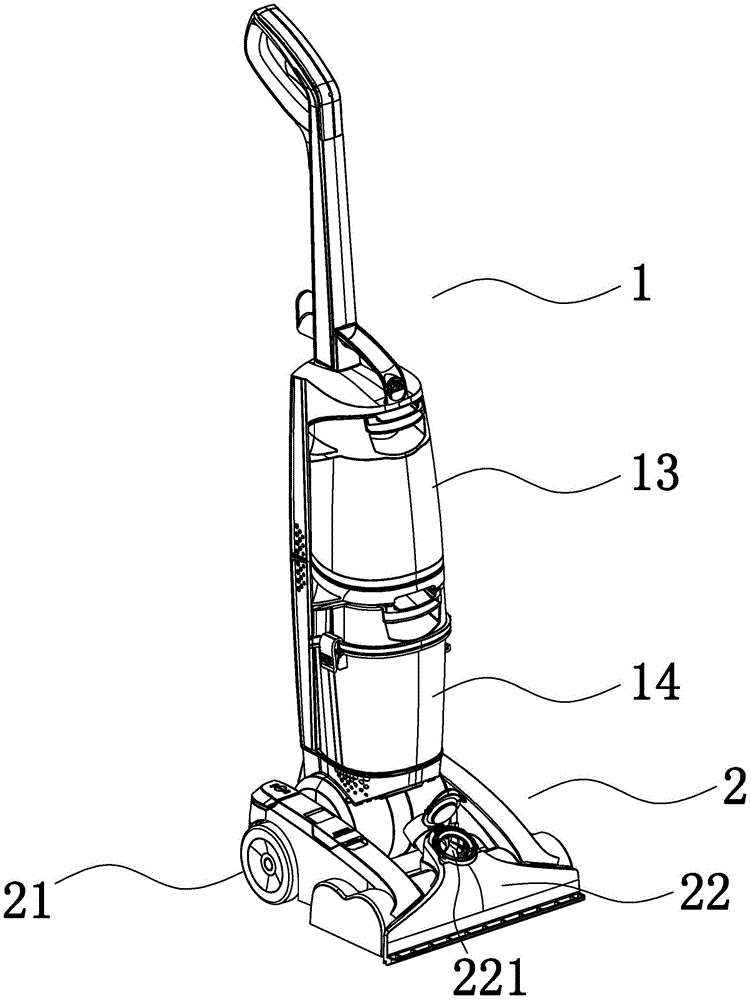

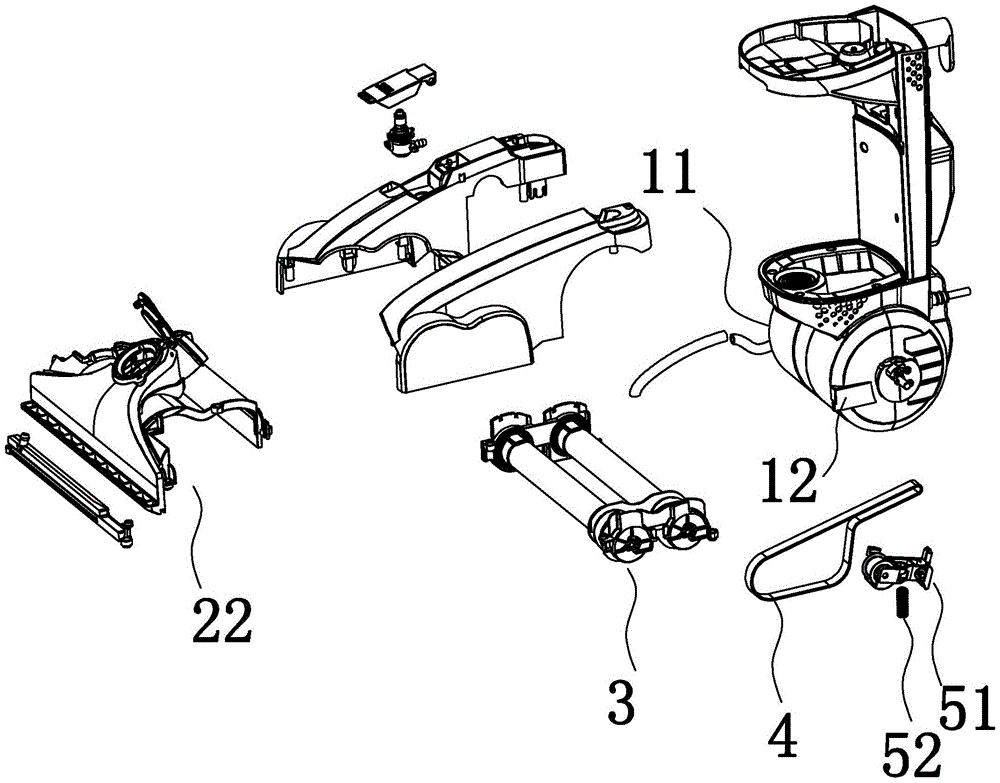

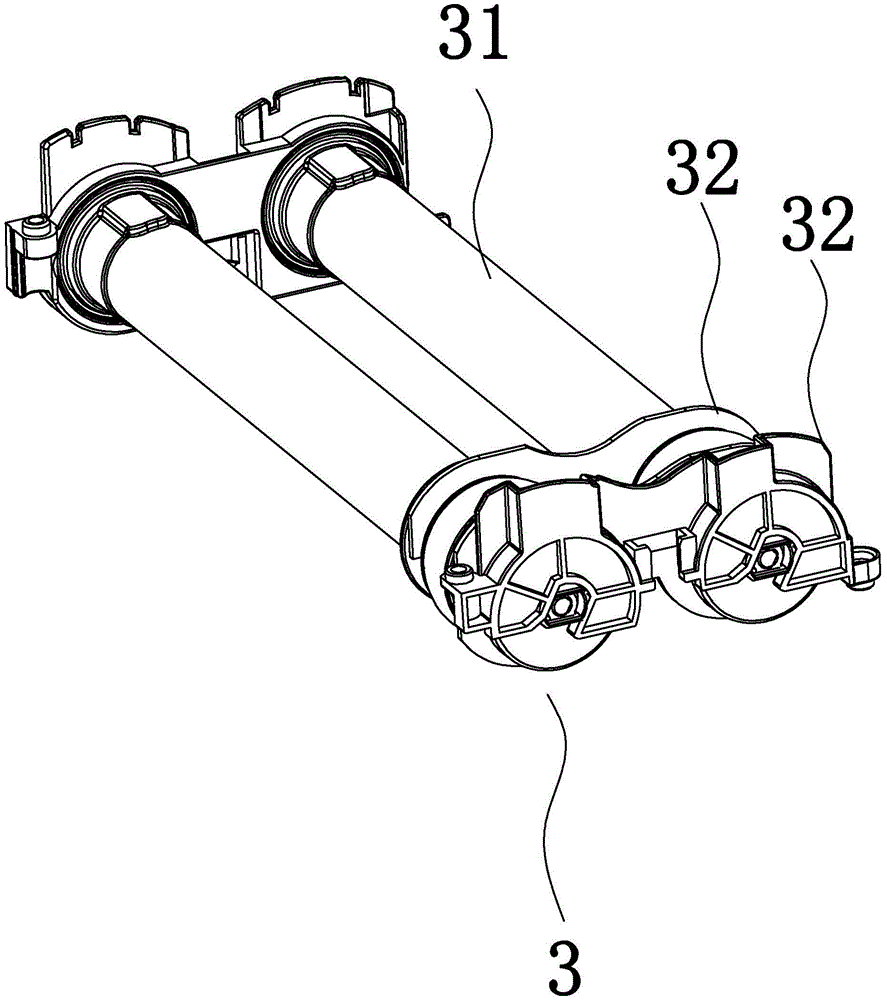

[0026] Example 1: Such as Figure 1 to Figure 6 In the illustrated embodiment, a cleaning machine structure includes a main body 1, a floor mop 2, a clean water bucket 13 and a recovery bucket 14 are provided on the main body, a sewage suction nozzle 22, a pair of ground wheels are provided on the floor mop, and the main body The lower end of the body is rotatably connected to the ground mop. The ground mop is provided with a double roller brush structure 3, which includes two parallel roller brush shafts 31. The roller brush shafts are provided with bristles and the lower part of the main body There is a motor shell 12, a power motor is arranged in the motor shell, and an active pulley driven by the power motor is set on the ground mop. A drive belt 4 bypasses the active pulley and two roller brush shafts. The drive belt is closed end and end A belt loop is formed, the inner loop surface of the belt loop is an inner belt surface, the outer loop surface of the belt loop is an o...

Embodiment 2

[0033] Example 2: The basic structure and implementation of the present invention are the same as Example 1, the difference is that Figure 7 , Figure 8 As shown in the above, the barrel body is provided with a baffle 145, a vertical pivot arm 146 rotatably connected with the baffle is provided on the baffle, a pressure block 147 for contact with the float is provided at the lower end of the pivot arm, and the upper end of the baffle is provided A locking rod 148 that can move to the float arm and a compression spring 149 that abuts the lock rod against the upper end of the swing arm, and the upper end of the swing arm is provided with a contact portion against one end of the lock rod. When the water surface shakes violently, which makes the float swing larger, the float will contact the pressure block to push the rotating arm to rotate. The upper end of the rotating arm acts on the locking rod, and the locking rod is pushed out to the float arm to lock the rod end. The part ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com