Positive and negative pressure coupling foam jetting device

An injection device, positive and negative pressure technology, applied in the field of foam fire extinguishing, can solve the problems of incomplete foaming, good fire extinguishing effect, poor foam stability, etc., and achieve the effect of saving gas consumption, low gas consumption, and good foam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

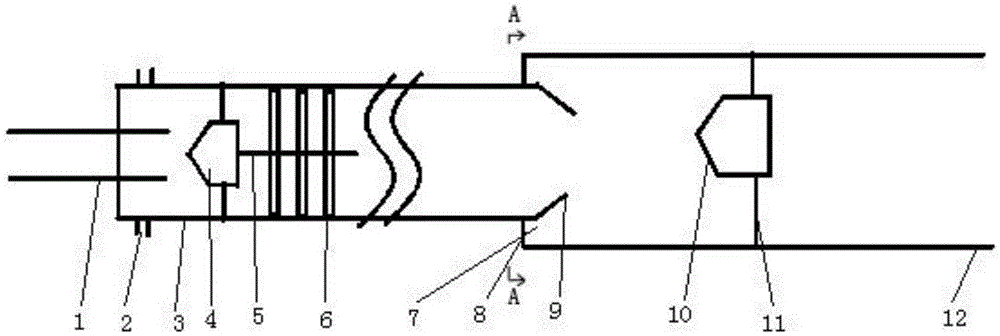

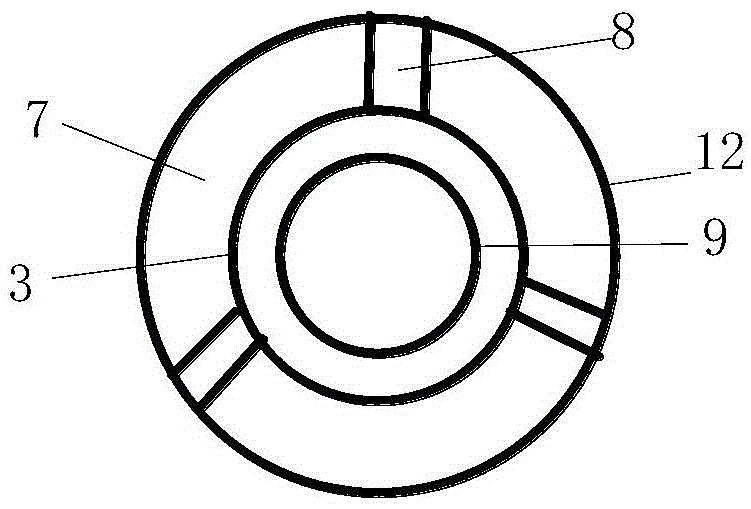

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0020] Positive and negative pressure coupling foam injection device, including liquid suction pipe 1, gas injection hole 2, gas-liquid mixing pipe 3, primary spoiler 4, secondary spoiler 6, positive pressure foam injection port 9, foam injection pipe 12 and three times Spoiler 10. in,

[0021] The diameter of the gas-liquid mixing pipe 3 is smaller than that of the foam injection pipe 12 .

[0022] The liquid suction pipe 1 is connected to the rear end of the gas-liquid mixing pipe 3; a foam mixed liquid fire pump is arranged behind the liquid suction pipe 1 for injecting the foam mixed liquid into the liquid suction pipe 1.

[0023] The gas injection hole 2 is arranged on the circumferential side wall of the rear part of the gas-liquid mixing tube 3 . This gas injection hole 2 can have one, also can have a plurality of. When there are mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com