Shaking type wood polisher

A polishing machine and wood technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve the problem of reducing the control accuracy of the lifting frame, the inability to perform multiple times of repeated polishing, and affecting the polishing effect and polishing efficiency and other problems, to achieve the effect of force balance, fixed structure stability, low precision and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

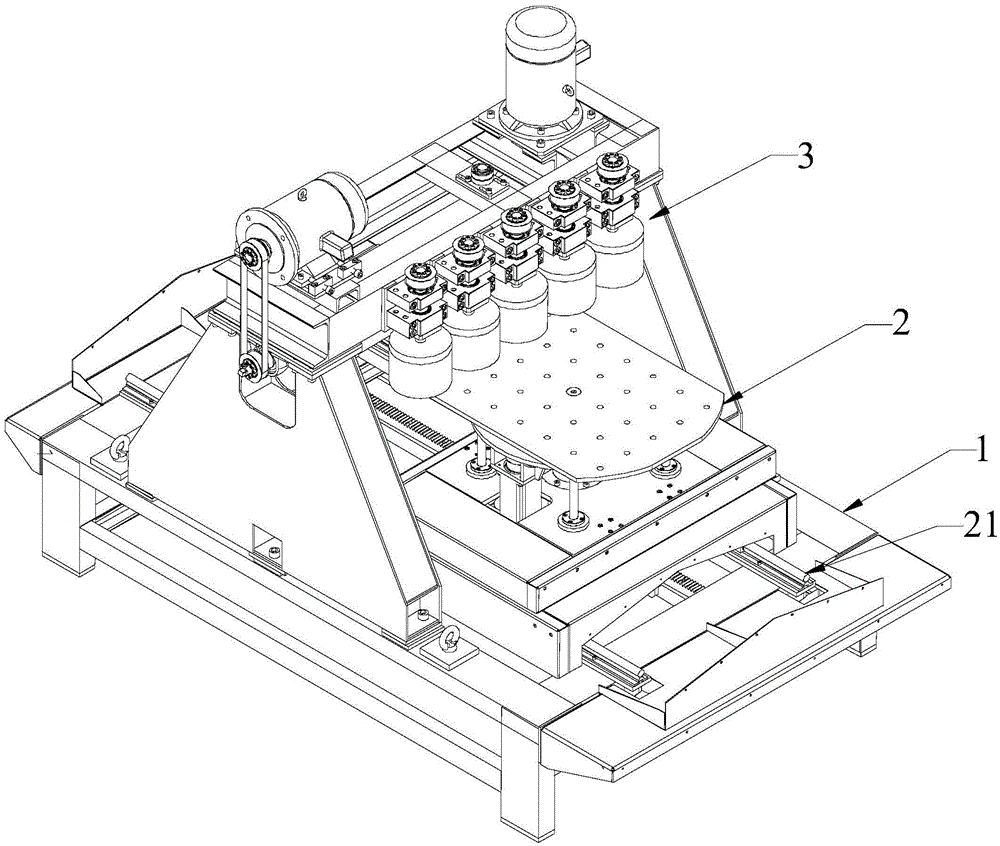

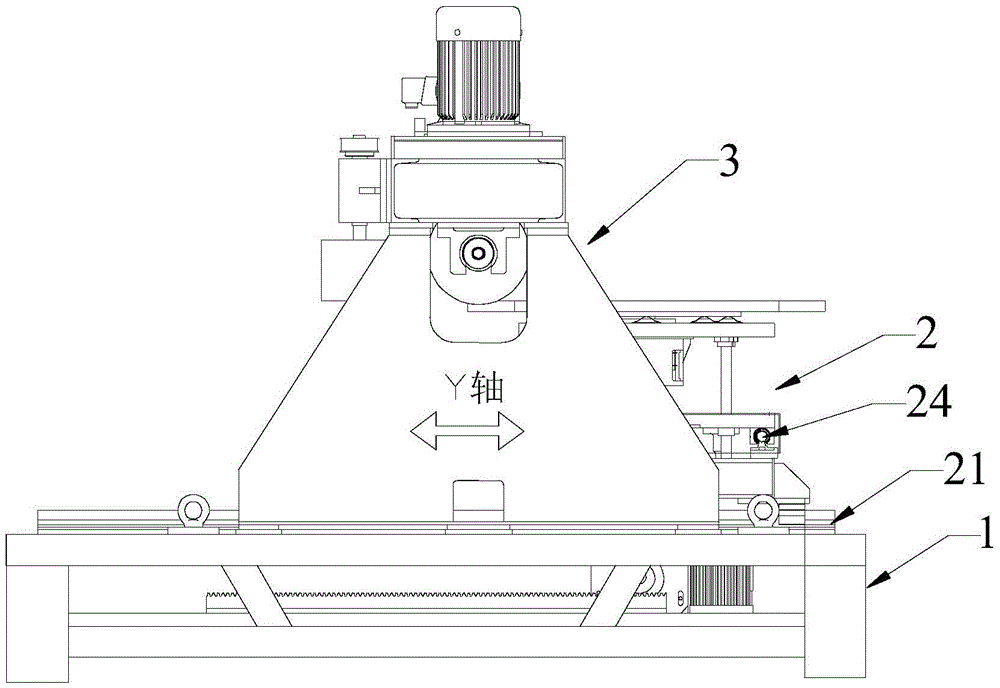

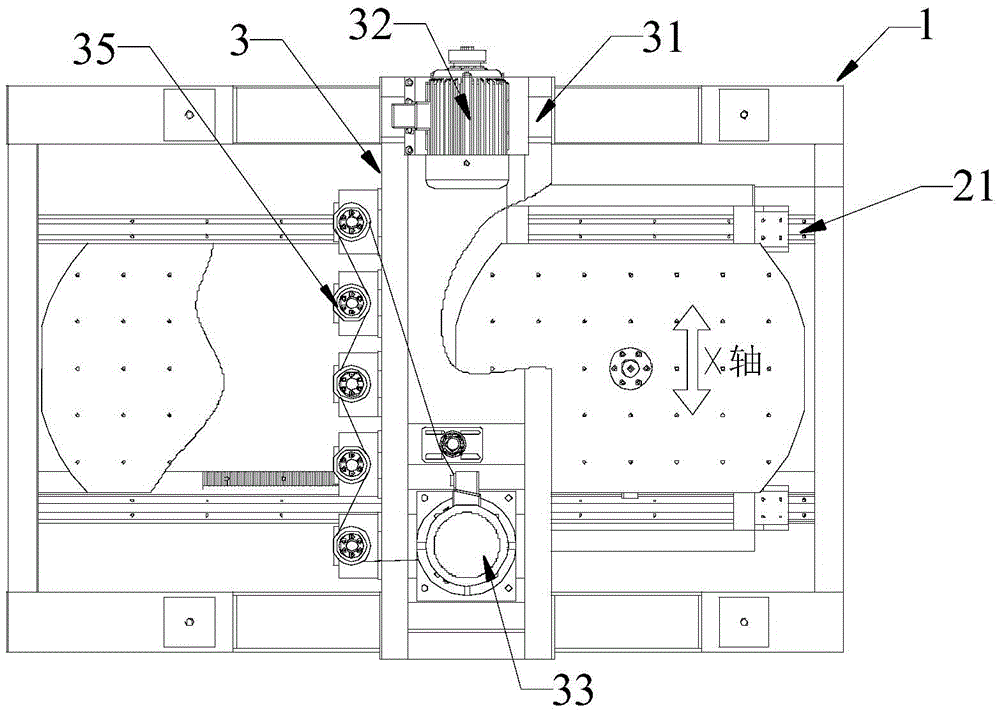

[0040] see Figure 1 to Figure 4 , the embodiment of the present invention discloses a rocking type wood polishing machine, which includes a frame 1, a polishing wheel module 3, a workbench module 2 and a numerical control device, and the workbench module 2 and the polishing wheel The module 3 is arranged on the frame 1, the polishing wheel module 3 is located above the worktable module 2, and the numerical control device is electrically connected with the polishing wheel module and the worktable module respectively, and the numerical control device is used to control the polishing wheel mold groups and workbench mods for polishing. The position and height of the polishing wheel module 3 are fixed, mainly to control the rotation of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com